-

Posts

9 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Charlie Eberhardt

-

-

I got some cracking but I'm dealing with it.

-

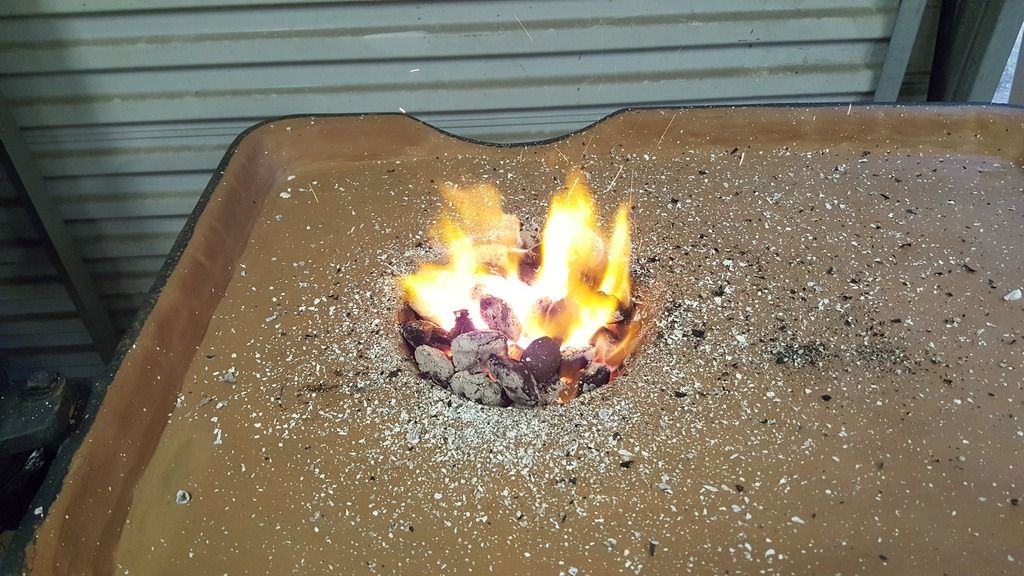

I finally fired up the forge today and threw a railroad spike in. I got to beat on it a little and learned a lot of things.

-

Hello. I am an aspiring blacksmith. I haven't even started yet but I have enough stuff now just looking for time. Too many projects. I'm in NE Florida.

Other interests include air-cooled VWs mostly...I have a few. I also have a Jeep, a camper, a pontoon boat and a few atvs so not much spare time.

I welded for a living for a number of years, then spent six years as a manufacturing engineer then moved into management. I'm currently a Plant Manager for a local manufacturing company with about 100 employees reporting to me.

I'm not sure why I decided to get into blacksmithing. I guess it seemed natural after working with steel for the last 25 years. I also have a number of hammers so I want to make my own. I bought a small Mouse Hole Forge anvil from a dealer and that started me on my way. I started to build a forge but then a nice one popped up on craigslist so I bought it. Right now, I have everything to get me started so...more soon. Somehow I ended up with three anvils and four post vises. I plan to restore the vises and then sell two of them. I also have about eight machinist vises. I need to put Sanford & Son above my garage door...lol

-

I started claying my forge today. I am using regular construction clay given to me by a buddy. It is basically some grey and red clay with some sand mixed in. I may try to add some more sand in the final layer.

The clay was a little too wet due to rain but it dried pretty quick as I worked it. I spread out a layer about half an inch thick and worked it in by hand, then with a small piece of RR track, then with the mallet and dead-blow. I let it dry for about five hours and the came back and pounded it again. I had some cracks and some soft spots. This layer is probably 1/8" - 3/16" thick now after pounding it in four times. Tomorrow, I will add another layer and make it a little thicker.

Comments and suggestions welcome.

-

Awesome...just what I was looking for. I bought a forge from a semi-local "dealer" and it has "Clay before using" cast into it. I have some clay/ sand mix from a construction buddy that I will use. It's in a plastic tub outside so right now it's mush but I will pull some out to dry a little before I need it.

-

10 hours ago, ThomasPowers said:

There are about 200 english anvil makers not in AinA as different ones keep popping up; Postman has mentioned updates to A&A as he learns of more. I'd contact him directly to see if he has info on that maker. Web searches suffer from the black swan problem of inductive reasoning.

What does the bottom of that anvil look like?

I will try to get pics tomorrow. I haven't turned that one over yet.

-

9 hours ago, Frosty said:

Welcome aboard Charlie glad to have you. Please don't take a mill to that fine old lady you'll do more and permanent damage to it that the pitting represents. every .0001" steel you remove from the face is decades of life. More anvils have been ruined by excellent machinists and expert welders than "repaired or restored" by same.

All it needs is some hot steel and a hammer to shine it up. If for some reason you need a pristine face make a bottom tool by welding a hardy hole size shank to a piece of heavy plate and you're home free.

Okay, that said why are you asking us about these anvils. Are you a dealer or looking to have them appraised for you?

Frosty The Lucky.

OK, milling the top is out. I was pretty sure it was a bad idea. Thanks. I'm asking for identification help just for my knowledge. No, I'm not a dealer...just a guy that became interested in blacksmithing and in the course of looking for an anvil ended up with three...and looking for more. I welded for a living for 17 years before engineering and management roles so I think blacksmithing is a natural progression for me...lol. I can appraise them myself if I should want to sell them by doing comps on the area I'm in. Prices are pretty high, in my opinion, right now for all anvils. I read somewhere that there is a TV show about blacksmithing so I'm sure that has a lot to do with it. I know Barrett-Jackson has everyone thinking that rusted pile of project car in the back yard is made of gold...lol.

13 minutes ago, ThomasPowers said:What is the evidence that points to William Foster? My WF is squatter and marked in CWT and stamped william foster with the date.

Maybe I didn't write my question correctly...it doesn't look like a William Foster to me at all and it says Williams & Co on it. When I search, the search results always take me to William Foster. On the AIA page, I didn't see Williams & Co on the list. I'm just looking for some info if anyone knows anything about this anvil.

Thanks

-

I have three anvils and a couple ASOs.

Anvil 1: Mouse Hole Forge 132 lb - ring and rebound both good, surface is a little pitted. I haven't used it yet. I have access to a vertical mill and would like to shave 0.060" or so off of it but I know enough about anvils to know I don't know how to fix one so I'm hesitant to mill it.

Mouse Hole Forge and blue no name

Anvil 2: No name anvil - around 150 lbs or so. I haven't weighed it. It had blue paint on it when I got it. I hit it with a wire wheel trying to find some markings but I haven't found any. This anvil has a lot of dents in it and looks like someone intentionally punched "divots' all over it. There were some red painted lines on it. Excellent rebound.

Anvil 3: Bought as a "225 lb no name anvil", I hit the sides with a wire wheel and found "Williams & Co" (I think) and "235" on it. It is in nice shape overall. Excellent rebound. I can't find any information about this anvil. Everything points to William Foster but I'm not sure if that's the same.

Hello from Florida

in Introduce Yourself

Posted

When I search craigslist they are all over in the northeast. Upstate NY and CT are loaded with blacksmith tools. Florida...not so much.

Take the family on a Florida vacation and buy one on your way home...lol. I am going to keep two and sell two.