-

Posts

7 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by BuchananFire&Iron

-

-

No sir, only the top rim with the brake rotor used as the fire box.

-

It may be crude, but it gets the job done.

I still have a few modifications to make, it's a work in progress project.

-

19 hours ago, Michael Cochran said:

I don't find my way out there very often but I know where you're at. If I can ever get things straight around here I'm supposed to have jwilson over and I'll let you come by too if you want.

Are you a member of the Alabama forge council yet? I would suggest joining if you haven't.

Just let me know Michael, if it's where I'm able I'd like to.

No, I'm not a member of the Alabama Forge Council. Actually, I have just started doing smithing as a hobby, like I needed another "iron in the fire".

I'm a life long metal worker, complete from machinist to welding to Certified Welding Inspector. Currently working in the design engineering department as a design/detailer. It's in my blood so I thought I'd give blacksmithing a try, so far it's ADDICTIVE!

21 hours ago, jwilson645 said:WOOT! Another local!!! Welcome to IFI.

Thanks jwilson!

-

4 minutes ago, Michael Cochran said:

There's plenty of us on here from Alabama. One of us might be pretty close by.

I'm currently in the Horton area in Marshall County.

Hayden is just down the road a piece from me.

-

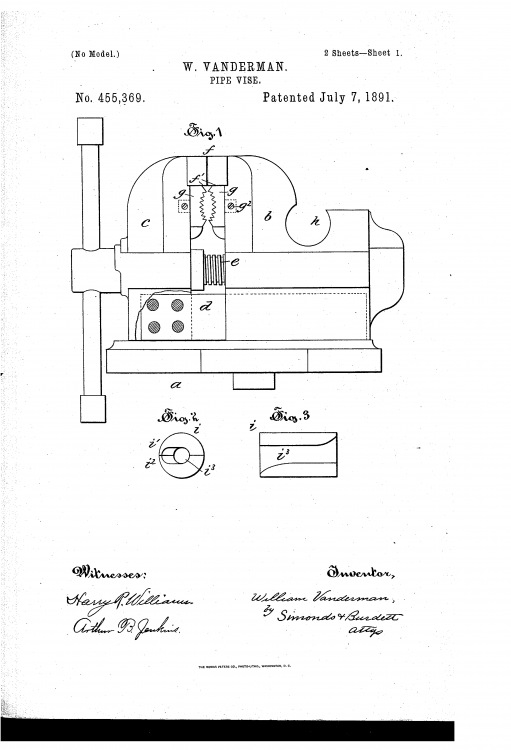

A little information I found on the vice.

Vanderman Manufacturing Co.was established in 1878 by William Vanderman and was located in Willimantic CT. The company manufactured heavy steel tool chests used by railroads and construction trades. Some of the smaller chests were used by The Wells Fargo Express Co. and were used as boot-boxes on stage coaches. Vanderman Manufacturing also made combination bench and pipe vises used in the steam fitting trade and was considered the best vise ever made. Vincent Nesci purchased the plant in 1966 and moved it to its present location in East Hampton CT. Nesci Enterprises, Inc. makes Concrete Saws, Welding Fixtures and prototype parts.

W. VANDERMAN' PIPE VISE.

N0. 455,369. v Patented July '7, 1891.

UNITED STATES PATENT OFFICE.

The main body of the vise is provided with an open bending-socket h, that is located back of the main jaw, and is adapted to hold the removable bushing 'i, that is preferably made in two or more sections 2" 1', having the tapered and rounded openingz' therethrough. These bushings fit into the bending-socket h in the vise, and are held against removal by the overhanging upper edges of this open socket. A pipe of considerably less diameter than the bending-socket may be placed therein and the sectional bushing slipped into place and the pipe then bent to form an offset in the pipe, or it may be bent in opposite directions upon opposite sides of the vise, the sectional bushing being slipped out in parts, so as to enable the pipe to be removed from the hold of the bushing and socket.

REFERENCE PHOTO

-

My forge

in Solid Fuel Forges

Posted

Thank you for the suggestion. Actually that's my next modification in conjunction with a fuel table built around the notches while at the same time cutting down on the depth of the firepot because as it is, it's to deep for my likening.

Thanks for the compliment. Right now the perforated grate is working well. I do already have a coal burning stove cast iron grate on hand for a backup plan.

Living in the south does have its advantages. I don't have to much to worry about snow and extremely cold temperatures. But I do have plans in the works to have my work area completely covered before winter gets here.

Thanks for all the comments and suggestions, they are all welcome.