CWest

-

Posts

26 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by CWest

-

-

-

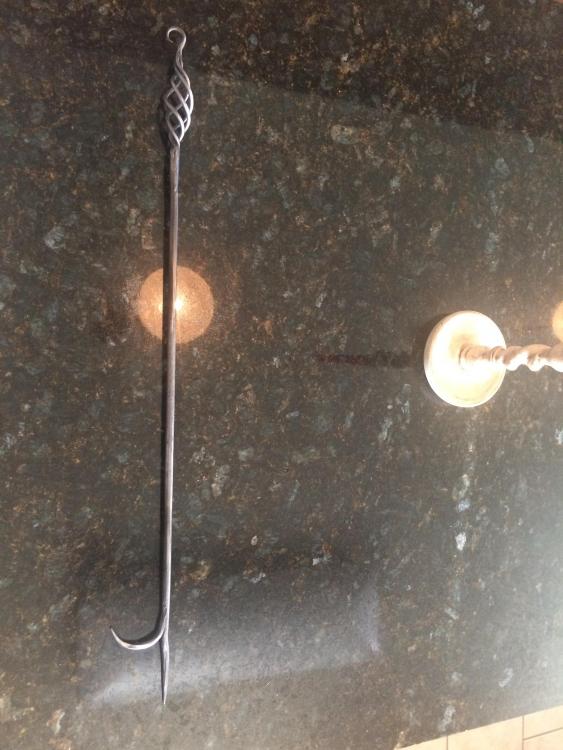

This one was a great learning experience, a lot of forge welding practice.

The twist is borrowed from John at Blackbear Forge. I wanted to see if I could do it, plus wanted another opener.

Take away was to make sure the twists are even, and try to add more material for the opener end. I grew worried I would split it as I drifted it larger.

-

I have a Sears anvil just like yours. I have been using it for 2 years now, along with a smaller Fisher anvil.

I love the Fisher, but the Sears anvil has it’s uses. It has much better edges for when I need to isolate material.

I wouldn’t fret, you have a usable anvil. However, like others have stated, keep the missed hits to a minimum, be careful when cutting, and definitely work your matieral hot.

-

JHCC, Aus, and JLP thank you for the suggestions. They will be put to use soon.

-

-

I have been using tie rods to make top tools with. I have not heat treated them. They have held up so far, granted they are not used every day. Should make a very serviceable drift, depending on what it is you are drifting.

-

-

1 hour ago, arkie said:

fishtail finial usually works fine for coat hooks

I haven’t tried those yet. I have been playing with John Switzer’s technique for ball ends and have done an angled type ( not sure of the name). My ball ends are no we’re near as nice as his, but just more excuse to practice. I’ll have to find the other hook and take a picture to illustrate.

-

21 minutes ago, Foundryman said:

everything looks very neat and uniform, good job, one to be proud of!

Thank you! The two biggest learning points were to slow down and pay attention, and reference marks drawn on the anvil are a huge help in keeping things uniform.

It is suppose to hold the kids school bags. My wife asked for something to help keep them organized. I agree that the hooks are too sharp for coats. I have been playing with different finials for those.

-

-

-

Knocked these out recently. The tomahawk(ish) is 4.5” OAL with 2.75” edge lenght. Second one I have done, I like this ones shape much better than the first. Made from 3/4” sq mild steel with leaf spring forge welded for the cutting edge.

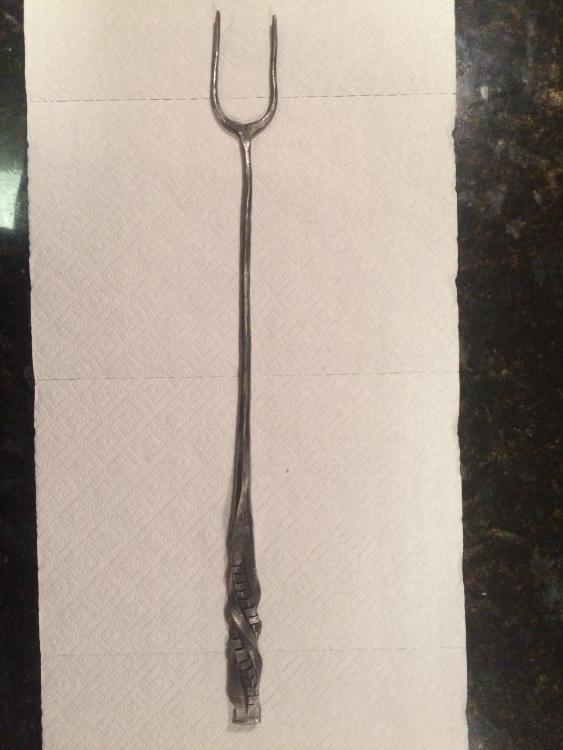

The second item was made for my wife to help hold up her hair. I expect it will see more use when my two boys are older ( pointy things and young boys usually don’t mix well in my experience).

-

-

-

Very true sir.

The hub also has two holes were a 5/8" bolt (IIRC) passed through. I am thinking of slicing through the center on the long axis in order to have a short round swage. Then I am planning on drill varying sized holes in the section where I cut my "flatter" from for a bolster. If I have enough area, I want to drill 3/8" through 3/4", stepping up in 1/8" increments.

-

I would not have thought of that. Thank you for the great idea.

-

A buddy of mine has a 1966 Ford pickup that he refurbished. In the process he bought a 67 Ford frame and used the transmission in his truck. He stored the 67 frame in my barn and last weekend we set out taking the front end components apart. We took one of the hubs off the front end and as I was inspecting it I saw a tool I've been needing. Sliced a bit off on the porta band and ground it flat. It is 2" in diameter, should serve as a decent flatter.

-

Almost too much fun. Hammer arm was a little sore after swinging my heavy hammer on the jack hammer bit. Good exercise for sure.

-

Started Friday evening with the little hooks. We use them in our storage room. Then grabbed a jackhammer bit I've had for a while and made a cutoff hardy for my Fisher. It's not pretty but it works well. Today I was home early and my daughter asked me to make her another leaf, she "helped" in it's making. I then had 6" of 3/8" rd left over and made my first chain link. One down, many more to go.

-

That is the type of gift he will hopefully pass to his grandson someday, along with it's story.

-

-

I.P. and Frosty, thank you for the kind words. I really like the marble idea. I will give that a go once I become more proficient at the twist.

-

-

I have been using a stainless steel sink for the past year. My tuyere is a brake rotor from my car. I filled in around the rotor with 50/50 red clay/sand mix. The clay/sand mix insulates the sink well enough that I can touch the sides of the sink with my hand while a fire is burning. My only complaint at this point is that it is heavy, moving it is a two person job.

Tooling direction... need advice.

in Tools, general discussion

Posted

I really like that brazier. I had never heard of one until your post, now I have to make one. Thank you!!!

As to your question, I think you could benefit from Mark Aspery’s third book on traditional joinery. He shows many tools and techniques, so it may help you to narrow your focus on what tools you may want to make in the near future.