Gerome

-

Posts

5 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Gerome

-

-

A different approach would be to find a local laser cutting works and ask them to cut out a male and female die out of plate matching the width of your strip, include a 'notch' in the back to suit a 'vice grip' and them just 'press' them. I hope this 'makes sense ' . As the shape is quite simple it would not be that difficult to 'hand make ' the dies using a fret saw and a file.

Depending on the hardness your stock it might help if you aneal it first by heating and quenching in water.

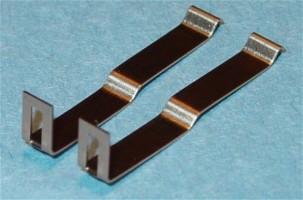

I have seen a one off tool that can do this, pictured, but I was looking for something simple. I have heated the quenched but did not try to flatten while heated but it is worth a try.

-

Okay, that's a whole different thing than we thought you were asking and a perfect example of wanting a specific answer to a vague question.

What you want to know is how to form the brushes and keep the contact area flat. This is easy peasy. Cut two pieces of smooth wood the same width as the flat contact area of the brushes. Measure and cut the stock and use a C clamp or vise grips to clamp the strips between the wood with the 90* bends on one side the the step bends on the other. Bend the 90*s then bend the other end close to the wood and clamp it to a table top or steel plate, etc. with a piece of stock, wood, steel, etc. the thickness of the step bends flat on the plate against the up bent strips. now just bend them flat against the bottom die. Forming the hinge/hook end is as easy as using a piece of steel wire or a nail and driving it against the copper on a piece of end grain wood.

Keep it straight and or flat is WAY easier than flattening/straightening it afterwards. It's easier to NOT make mistakes than correct them.

And don't tell me you needed me to tell you to unclamp the brushes from between the first two pieces of wood before clamping it to the large flat piece to make the step bends. Awe heck you can do it all clamped to a table top if you like. Seriously there are so many different ways of making this simple piece I'm in danger of getting seriously sidetracked by different methods and mixing them up.

No rolls, special shears, nothing special needed at all, just a bit of basic technique and care. Heck, the last set of slot car track brushes I made was what 50 years ago? I stopped playing with slot cars a couple years before I got my driver's license. I'm almost afraid to ask my sister if my old slot car box is in the piles of stuff my Parents kept. Pack rats, the whole darned family.

Frosty The Lucky.

I plan to give this technique a try.

I took left slots behind when I got my DL AND discovered girls. When I turned 50 I decided to get back into them as a hobby to keep me from running the streets. Seems to be working pretty well so far.

-

All,

Thanks for the quick replies. I race toy Aurora slot cars from the 1960's. The pick up shoes are copper and to get good contact on the rails you need the shoes as flat as possible. There are bends on both ends so a rolling press would be difficult to use. Below is a picture of the shoes and the portion that runs on the rails is the flat part just behind the slotted front opening.

I have a flat surface that I use to try to flatten them on but I need them really flatter than .020".

-

Hello all,

I'm trying to com up with a war to flatten thin copper strips for a hobby of mine. The strips to flatten are about .020" thick, .425" long and about .060" wide. I have several devices I'm trying to use such as a hammed and a iron anvil but can't seem to get them as flat as I want. I can provide pictures later.

Flattening thin copper strips - what would work best?

in Copper Alloys

Posted

The picture are of pieces already from but not necessarily flat on the contact patch. The .020 is the thickness of the shoe and it is actually closer to .015" when I checked it with calipers. They do get twisted sometimes but that is an easy fix as it is typically on the "hanger" which is at the far end of the picture.

Below is a picture of how they hook up with the springs providing tension. Notice the are actually disconnected from the slotted front end. And a picture of them connected.

I want to flatten the to improve the widen the contact patch to make the car run smoother and improve electrical contact. When not perfectly smooth you get arching which produces a blackened are on the contact patch thus further reducing the electrical contact. I have used 400 grit sandpaper to polish and you can actually flatten the patch in the manner is you sand long enough and have the patch flat on the sandpaper.

I have asked fellow racers what they do and some are quite about this and some forthcoming with information. Racers are always looking for an edge and that's what I looking for.

Thanks again for all the replies and suggestions.