-

Posts

52 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by EduBacha

-

-

One day I hope that I can buy or make one belt grinder like yours, they are really clean shaped and appears to be very comfortable for knife making.

I do almost everything with my Bosch grinder, the shape, grinding... only the finishing, that I do by hand with sandpaper. This Bosch is mine:

In the beginning it's a bit difficult to evenly remove metal from the knife blanks, but with some practice you can do a lot of thigs with few tools.

Bacha. -

Oh my god this is the most beautiful knife I've ever seen :wub:

Thanks for sharing, It's really stunning.

Bacha. -

Thank you!There is no tungsten. http://metallicheckiy-portal.ru/marki_metallov/stk/SHX15

oh it's very high carbon, really nice link, thanks!

-

That is nice... Those ball bearing are high on tungsten?

-

Hello Steel lovers,

I brought to you some photos of my last finished knife.

It's a kitchen knife made from SAE 1070 steel and cedar on the handle.

Hope you like it, it's very simple for my own use and I remove material of only one side os the blade, here we call it "unilateral grinding".

Photos:

Hope you like it,

Bacha. -

Nice!! I didn't know this material, very nice work, thanks.

Bacha. -

I liked both!

But I prefer the balance of the short one... The design seems to be very comfortable too.

I think that the short one with Tero Tuf finish would be very pretty!

Thanks for sharing,

Bacha. -

I need to try something like this... It's a pretty cool knife. Reminds me the Muela Kodiak! I love the shape of these knives.

thanks for sharing

Bacha. -

NICE one! I would carry one of that... Beautiful quench line.

Thanks for sharing.

Bacha. -

That's a beauty!

John

Thank you very much John!

Beautiful knife, nice shape and very elegant. If you don't mind me asking, why only one pin in the scales?

Thanks JME1149, the alone pin appearing is just a case of esthetics. There are 2 other pins under the wood and some pits on the internal part of the handle and scale wood. I used 10min epoxi to glue everything together, I think it's very strong but only time and use will give me the answer!

That is one great looking knife. I imagine it will do a lot of work for you and last your life time.

I do appreciate your words, thanks! It was made to be

abused ;)

that's purrty!!!

Thanks Jimmy!!

-

That's all for today, hope you like it.

I made this one for myself, so it's very simple and useful.

Thanks,

Bacha. -

Hello steel lovers,

It has been difficult to find find time to make knives. This one I've finished today:

Steel: SAE 1070

Handle: Canafístula wood

28cm of total lenght: 16cm of blade and 12 of handle.

The difference of color was made by eletrocorrosion and the darkness was made with perma blue.

Photos:

-

Perfect folding knife.

I saw 3k US$ knives for selling that were not a fraction of yours.

Thanks for sharing,

Bacha. -

This is fantastic!

I am trying to make one lockback folding kinfe in damascus steel... Soon I post the results, but your knives are a goal for everyonw here.

Thanks for sharing.

Bacha. -

That's amazing!

I think that make one of these knives is the target of almost everyone here.

Thanks for sharing!

Bacha. -

Bautiful blade and handle!

The blue color gave it a very attractive look,

Thanks very much for sharing with us,

Bacha. -

Hello,

Thanks again for the comments!

There is something that I find very entrancing about that knife. It's very crisply executed. I like it a lot.

Is that a Walther Alutec in the background?

Thanks for the words! That is a Walther LG 400 Exp. Alutec in the background, I am/was an olympic shooter but I had to stop it for a while because of the studies. So I mounted my Leapers scope on it while I am too busy to shoot on 10m Air Rifle.

Bacha. -

I want to say a BIG Thank You for the comments and support! I do aprecciate the writing of yours and it's a way to see if my knives are getting a little better with time and practice.

How does wax quench work? For my damascus, I quench in canola oil.

Kayakersteve, it's a simple process, I used the term "wax"but it's paraffin! (I will edit my post by the way).

I just bought some 7days burning candles and melted it on water bath, then I let it cool down for some hours.

To use for the quenching is very simple too: you let the metal reach the temperature that you need and carefully buries the blade into the paraffin.

It's nice to control the depth that the blade will dive into the paraffin, because with this process you can harden the edge od the blade and keep the dorse of the blade soft to make some file work later.

I do warm the paraffin before the quench, I just let a thin layer of the paraffin gets melted (with a small torch).

Doing the quench using paraffin, you have less chances to get your blade warped too.

Hope that it was enlightening enough, If don't, I can take pictures of the process.

Thanks again for everyone that commented on my topic,

Bacha. -

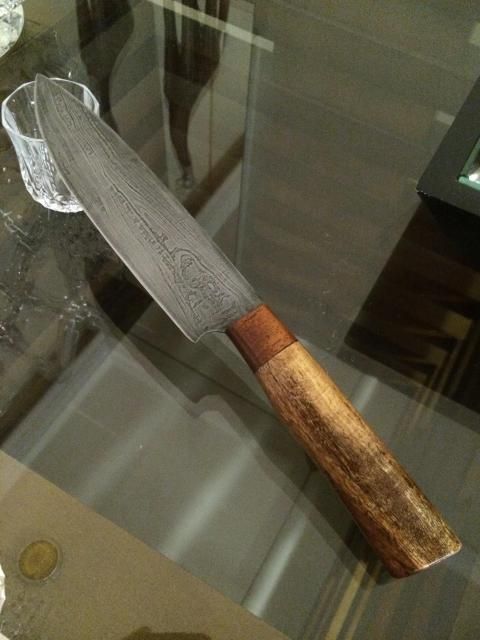

Hello steel lovers,

I brought for you one of my recent finished knives, hope you like it!!

Steel: Damascus 1080x15n20 twisted pattern.

Blade lenght: 7,5cm

Handle lenght: 8,5cm

Thickness: 4,5mm

It was quenched on wax and placed for 45 minutes at 250ºC to temper.

Photos:

Hope that you like it as I liked to make this small necker knife.

Thanks a lot,

Bacha. -

That's sweet!

Thanks for sharing,

Bacha. -

Hello,

I feel glad to read these comments, Thanks very very much!

It's good to see that steel lovers more experienced than me liked my knife.

Bacha. -

More photos of the handle:

That's all for today,

I just fell in love with this wood, It's some kind of Ambrosia made by brazilian nature... :D

Hope you like,

Thanks,

E.Bacha. -

Hello,

Long time no post... But I brought something that you might like to know: an exotic wood from Brazil that I used on this handle. Let's take a look!

Steel: Damascus 1080x15n20 396 layers twisted pattern

Wood: Sibipiruna (and something that I would call it as a bolster, made from Imbuia).

Forged knife with 15cm lenght blade and 12 cm of handle.

Finished with cyaniacrylate

Quenched in oil

1 cycle of tempering at 240ºC during about one hour ( till the blade gets light yellow color).

It's good to mention that, as I did on my other BBQ knife posted here, I grinded it on just one side, so one side of the blade is completly flat, like the edge of sushi knives.

And the thickness of the blade is 3mm (0.117')

I know that you like: PHOTOS!

-

Beautiful knife!

Loved the quenching line and the handle.

What did you used to put the dark color on the blade? Mn3(PO4)2? FeCl3?

Thanks for sharing this very good looking knife.

EB.

Show us your knife grinder

in Grinders, Sanders, etc

Posted

SJS thank you very much! I never tried to make the hollow grinding on a knife!

Actually I am using a 14' file to remove more material and keep the grinding flat, working with files is very nice despite the time spent...

And argentina has very good prices, I buy deer horns from there ;)

Bacha.