Darlhim

-

Posts

29 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Darlhim

-

-

No there isn't.

The hole the burner actually goes into is almost the exact size of

The tube. Less than 1/8 gap. It's being used fully outdoors anyway not really concerned with CO? -

-

I'm just painting the outside black. Plenty of forges are painted as far as I can see.

-

Just an update.

I did in fact succeed with my forge build. Its almost done at this point, I put the rear plate with a 2.5" x 1/2" cutout on as well as the front plate. (neither is on in these pics)But it does make that steel yellow hot in a matter of a 2-3 minutes at max temperature.

I have the burner tube about 1/4" above the refractory and I achieved a really nice swirling flame. I added a larger bell to the end of the burner. Between the Reil Burner and oliver upwind burner, both performed but the reil burner was the clear winner.

Side note, I picked up 2000 degree spray paint. Is that necessary or should I just go with BBQ paint?

Thanks for all the help.

-

So apparently my problem was simply lighting the burner from the rear and not the tip

It works great now.

My LAST questions and id really appreciate help because I can't find the answer. Does it matter if the reil burner tube is the full 8" or will making it slightly shorter be ok?

Would I be better off with a 1.5" to 3/4" bell then a 1" to 3/4" bell. -

How does it perform in the forge?

Not at that point yet. I don't want to cut a hole into the body of the forge until I know i have a working burner. Everyone else seems to get them working in open air I don't understand why I cant.

-

Today I built the Reil burner following instructions I found.

3/4" pipe 8 inches long. #57 hole for the propane.

It still isn't getting me that jet flame I see everyone has. What am I doing wrong here? I'm about ready to throw in the towel starting to get pretty bummed over this. Just throwing money away making these burners.

This is the new burner from 0-20psi.

-

I apologize I should have stated I am now using a 0-20 psi regulator.

-

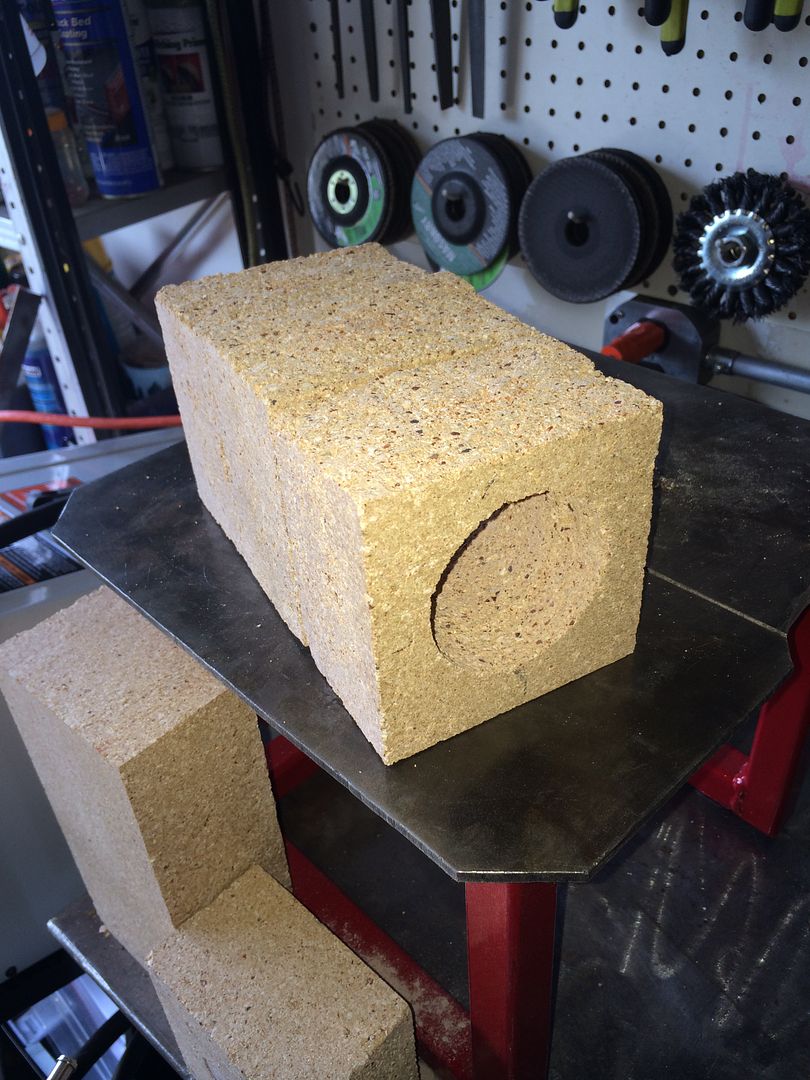

So I have the actual refractory structure completed.

My burner seems to be not how it should. I think I am going to salvage the brass and build a replacement Reil style burner which seems to be the most popular.

The issue with my burner is that randomly the flame will shoot out the air holes near the base which is very dangerous and if I turn the pressure up, the flame escapes the tip of the burner and just becomes extremely violent and not any more effecient.

My final question hopefully someone chimes in, what do I do about a flare? Does it need a flare inside of the actual forge? Should I care a flare shape into the refractory where it meets the burner?

-

Would I be better served by a square cutout for the forge way or circular?

I assume the circular tunnel would allow Better heat flow but reduce forging space.

The bricks will be 4.5" square. I was going to go with a 2.5" square or hole. -

How does it perform inside the brick? Many good burners only work inside the forge due to lack of back pressure outside the forge

Honestly I am not fully certain yet. I haven't cut the real brick to fit inside the forge yet. I put it inside of 3 of the hard style firebricks I had and it didn't improve. But I just kind of had it on a table pointing into the tunnel so I don't really think it would count as a conclusive test.

Does everything about its design look like it should work?

Heres where I am at so far with the actual body.

-

Ok so I don't know where I am going wrong that the burner in the post above works so well. Mine doesn't seem to have the same effect.

What do you guys think I need to change?

This is my burner.

#57 hole. 6" long, 3/4" pipe

I realize it has no flare but I did try it inside of a round tunnel of bricks to try and simulate it being in a forge and it didn't really improve. In the video its probably at around 7 psi. If I crank it up any more the flame starts to become turbulent and pull away from the tip.

-

Thanks for the advice. I changed my plan I decided to get a 5" steel tube that will perfectly fit the bricks and it will be cheaper.

-

Honestly what I want to use is a stack of soft fire brick. Casting is way more unnecessary work.

My problem is that I cant find a local supply of soft fire brick on Long Island or NYC and shipping for the only place I've found is $17 for 3 bricks. -

Honestly No I was not.

I was trying to copy the design of the "atlas mini forge" which appears to just be brick on the inside.

Would I be better off just dropping the casting and putting inswool on the inside with a brick floor? I'm only looking to heat treat but forging temperatures would be nice. -

Honestly couldn't find any info on the manufacturer to call them. Googling Kast o lite only results in vendors sold by the 5lb bag and up.

The volume I'm working with on paper should be a 225 cubic inches. That's after subtracting the area of the forging space down the middle. -

I searched around for a while and came up empty for this question so I apologize if I somehow missed it.

I decided to go wjth a 6" square steel tube as my shell for my forge and was thinking casting a refractory inside it would be my best bet.

My issue is, I have no way of knowing how much refractory to buy. I'm looking to keep the price as low as possible.

For a 6" x 9" square tube with a 3" tunnel down the center, how many lbs of casting material would I need?

I found this stuff on amazon that would work but it is only rated to 2000 degrees which may not be enough? -

For some reason I have to post in tiny one sentence edits. I can't post an entire post in one shot.

Ok so I need something more like this

http://www.amazon.com/Bayou-Classic-Adjustible-Regulator-Assembely/dp/B007PS0938/ref=sr_1_4?ie=UTF8&qid=1403378881&sr=8-4&keywords=high+pressure+propane

Could anyone offer some insight as to how the atlas forge burner works? I feel like it couldn't be that hard to make. It looks like its just the outlet tac welded to a piece of pipe?Why does that burner function so well without a flare or large air inlets?

-

Can't post reply? Its telling me I don't have permission if I try to post what I am trying to ask...XXX

Is it an issue if the propane line im using is a pre-set BBQ regulator hose? I'm feeling like it doesn't permit enough gas flow.

Right now I have basically achieved a bunsen burner on steroids.

How is this burner built? It seems substantially simpler than any other design but is there some secret to it? The main thing I notice is the 20psi regulator. Which is technically double the 10psi output fixed one I purchased at home depot.

Also, did I get the wrong bricks? The mason supply yard said these were the fire bricks they carry. They aren't as soft at all as the other bricks it looks like everyone else uses. I had to use a carbide grit hole saw to get through them....

-

So, to make this burner am I just putting a 1/2" T together with a 1/2" pipe, and attaching a propane source

To a mig welding tip? -

I'm on Long Island I have plenty of BBQ tanks, il just use one of them.

-

If I build a burner, will it work fine with camping cylinders or do those burners need a large cylinder?

-

I'm only looking to make a small 2" or so chamber maybe 6" long.

Would putting a 2" steel pipe inside the 2" tunnel in the fire brick benefit me at all or will bare brick be ok.

This is just going to be for knives and maybe some random stuff here and there. -

Also if I built my own burner, will I get more pressure/volume out of a camping cylinder as I would 20lb cylinder or would the heat output be equal?

Does aluminum really need a full foundry?

in Smelting, Melting, Foundry, and Casting

Posted

I looked around a bit on the forum and don't really such much pertaining to the idea im thinking of.

Essentially, I just want to be able to melt down aluminum (probably from cans) into round ingots for turning on a lathe.

Is it really necessary to make a full enclosed foundry or could I just get a crucible that would fit whatever I want to melt down, and build a stand that holds it above a large propane burner?

I see videos of people on youtube melting aluminum in ceramic pots and just heating the pot, but that doesn't seem all too safe. I was thinking of a steel welded frame that would hold everything snug.

Really all I need to know is will using a large propane burner directly fired at the bottom of a ceramic crucible effectively melt aluminum?

I'm talking a small contraption here, cheap and usable. Probably would use a crucible like this one