-

Posts

3 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Espen E

-

-

Hi Mike,

Thanks for the reply!

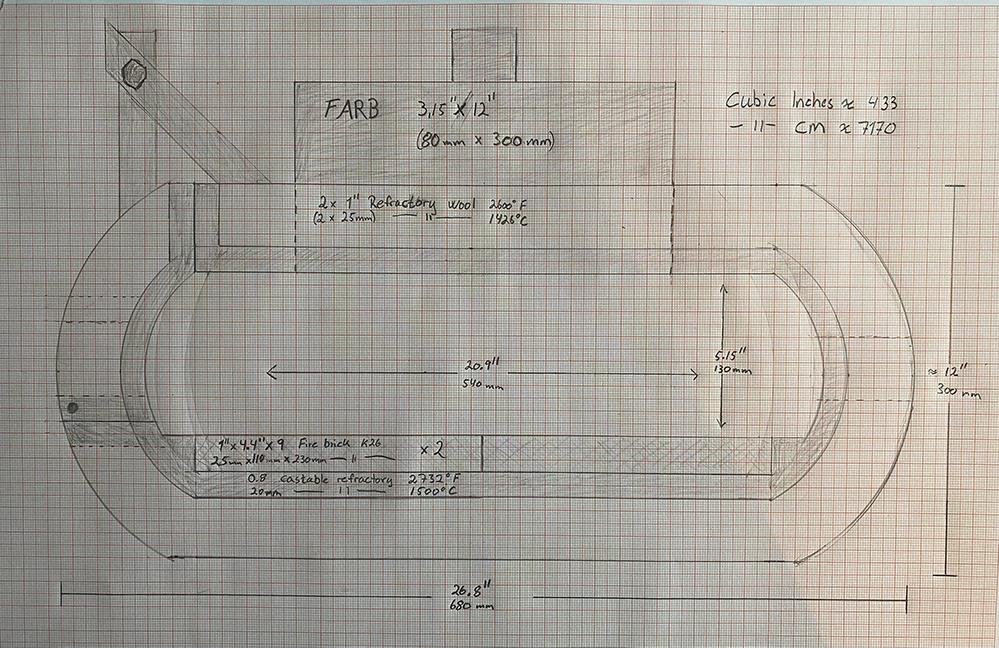

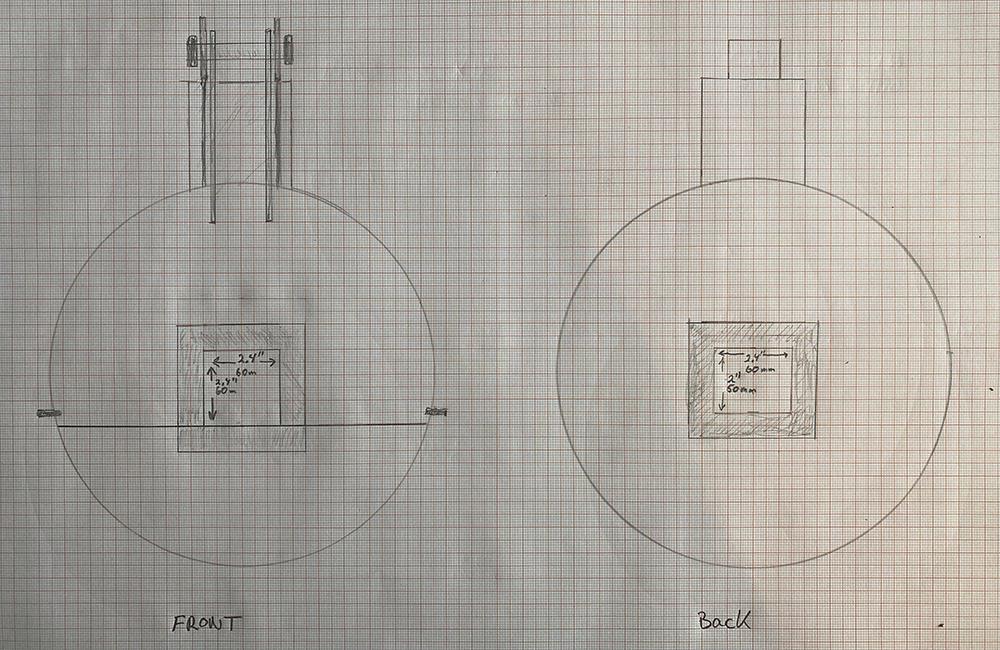

The drawings are made of the same forge. the first picture is a cross cut of the propane tank.. the other drawing is the front and back of the same forge.

I will do a search for a better alternative on the refractory. What about the exhaust outlets?

-

Hi,

I have been reading and tried to get some pointers on how to build a propane tank gas forge and have now made a concept drawing. I would really appreciate some feedback on my idea before I start building it.

Some background: I have been forging for some years and already have a smaller two burner gas forge but I´m now planning to get into the larger production of pattern welded knives. I like to make large billets so I can get 2-4 knives out of it, hence I want a larger forge to speed up the process. I´m in possession of a 50# machine hammer so I can move a decent amount of steel and want the whole billet warmed up to welding temperature throughout the whole process.

I have a larger propane tank that I will retire and use for this project and the dimensions are on the drawings.

Living in Norway it is hard to get all the stuff mentioned on this forum, but I have ordered insulation wool, Kaowool Rigidizer and ITC 100 HT from Canada.

I have found one manufacturer of castable refractory here in Norway Rated for 2730 Fahrenheit / 1500 centigrade with the following composition:

Borgcrete 50:

AI2O3: 50%

SiO2: 38%

CaO: 7%

Fe2O3: 1,3%

I told the manufacturer what I intended to make, and he claimed that he would not be worried to use it as a liner and for the ribbon burner.

I plan to make a FARB as instructed on Wayne´s site. I can only get 80x80 mm ( 3.15x3.15”) square tubes and plan to make it 12” long. Will that be enough on the size of forge I have planed?

Any feedback would be greatly appreciated!

Forges 101

in Gas Forges

Posted

Thank you Frosty,

I was planning to form the ends by hand, but if the round shape don't add anything I will make them flat.

Regarding your answer to the refractory I'm a little confused, are you saying that you thing it will hold up?

I know that the kiln wash is not the best, but I could not find the ones you mentioned. Guess it will have to do until I need to redo it.