KJack48230

-

Posts

18 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by KJack48230

-

-

On 10/24/2014 at 3:31 PM, Glenn said:

DO NOT build the stand until you find out the height of the anvil face that you can use comfortably.

Any arrangement of materials such as cinder blocks, bricks, boards, pallets, etc so you can raise or lower the anvil can be used for testing. You will want to start with the face of the anvil about knuckle height when standing erect with a closed fist. From there raise or lower the anvil until you do not have to bend over and allows you to feel comfortable when swinging the hammer.

My suggestion is to NOW place a piece of 3/4 inch thick wooden sheeting on the anvil face. Hit it 3 times with the hammer with the same swing and impact you would use while forging. Notice the crescent moon marks. 12 o'clock and the anvil face is too low. 6 o'clock and the anvil face is too high. 3 o'clock or 9 o'clock and your hammer is tilted. Adjust as needed until the indentations from the hammer are full circles meaning the hammer is hitting the wood flat and square. Use this height for a period of time and be sure you are comfortable with the swing, impact, and overall height. Adjust as needed to YOUR forging methods, keeping in mind you want a full circle imprint of the hammer.

Measure the height of the anvil face and build you new and permanent anvil stand to this height.

This has been covered in other threads and discussions on the site. You may want to look them up for additional references.That makes perfect sense!

On 10/27/2014 at 12:44 AM, Glenn said:Think of the wood as carbon paper (you may have to google carbon paper , grin)

I'm thinking anyone under the age of 40 may have to Google that! LOL!

-

8 hours ago, jlpservicesinc said:

very nice.. Congrats.. This past weekend there was an auction for a passed away smith .. 200kg southern german went for 2100.00.. I would have bid on it had the hardie hole not been 1.5".. I refuse to by an anvil with a hole larger than 1" now.. Though my 368 HB has 1.375"..

One can always make an adaptor for the larger holes.

-

Hate to say it but just north of 2G's. Impulse buys are the worst but I've never seen one so clean.

-

-

It's a shame we can't figure out the age. Is there a guide out there that could help?

-

7 hours ago, MotoMike said:

I don't see a plate on the face. Is it cast steel?

Yes there is, you have to look very closely but its there. The more I look at it the more I love it. I'll probably get rid of my other one's except my 205# Peter Wright. I think 2 200+#er's are enough.

-

Thanks, it just didn't feel right to take off metal that was put there over a hundred years ago.

-

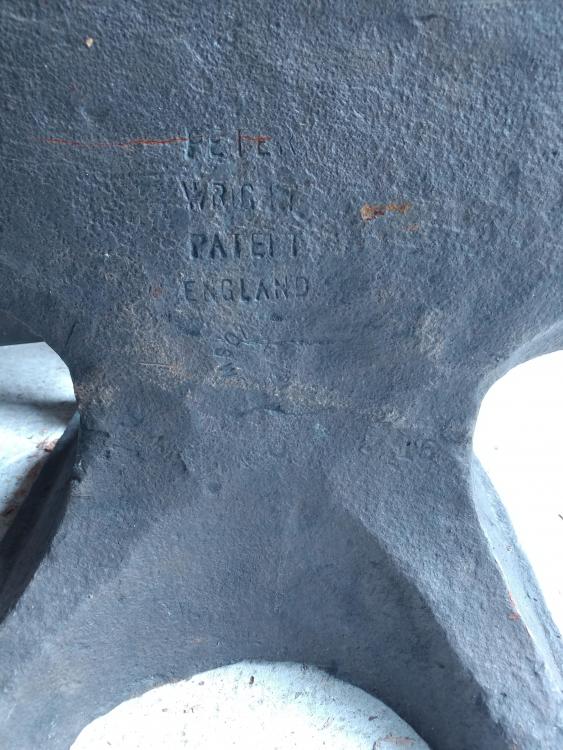

Good afternoon gents. Today at lunch I went to see a 340+ lbs Fisher anvil I was planning on purchasing but instead saw this and bough it instead. He thought it could be a very early example of a Peter Wright but because of the overly pitted surface from most likely decades of outside exposure there is no outwardly signs of who made it.

The weight markings are still visible as you can see so I'm hoping by the shape and style of the markings maybe it can be clues to the maker. The numbers dictate that it's 221 lbs and I'll confirm when I put it on the scale when I get home, it does feel like it's that much if not more.

The top surface is almost as pitted at the rest of the body but is amazingly flat. My 1" ball does a nice bounce of the pitted surface, nearly 80% return, and it has a very beautiful ring to it.

I'm hoping you all can help solve the mystery of what this is. I'm toying with the idea of milling the top surface smooth but a part of me says to leave it as is. What is your thoughts.

Thanks in advance to all that reply!

-

Hello, not sure where to put this topic so I guess I'll start here. Please direct me to another if it's available. I live in Grosse Pointe and would like to get some formal training before I kill myself. Any suggestions? I thought of on-line but having an expert on hand would make me feel a LOT better. Thanks in advance.

-

Thanks for the input, I'll be working on it this weekend and post some new picts afterword.

-

I was thinking that as well, use the chips as rads. Can you suggest how I should clean it? it has some rust on it and would like to remove it and coat it with something to keep it nice. Thanks.

-

Yup, scored this from that craigslist. Ended up giving him $250. Almost had him taking $200 but I started to feel guilty so I said $250 and he jumped on it. I was amazed that it was still available, it was on craigslist for almost two weeks. When I was on craigslist for other things I just tossed in anvil to see what popped up and up came this beauty. I threw out an email half expecting it to either say sold or no reply. When they said it was still available I moved like my a$$ was on fire. I am not sure of the second digit, it looks as if only the bottom portion of the number made it's mark, most likely the guy had it tilted when he struck it.

I live in Grosse Pointe, not the typical place you would find someone into forging but I'm not originally from here. I'm currently building my Monster Garage, 2 story 3 car with the man cave in the upstairs with 10ft ceilings. Thank heaven they recently changed the building codes to allow me to build this thing. I'm setting up the downstairs for wood working as well as forging. It'll be completed by the end of August. I'll have to take some pics to show what I've done.

Thanks for the feedbacks. I did think I stole this one. I'll have to do what Fatfudd suggested. How do go about doing that, just hit it with a grinder? I want to make sure I don't screw this thing up. I've been out there every day hitting it just to hear it ring... it's so beautiful.

I'll be posting a lot of questions over the next few months. I want to make sure I setup my shop just right. Thanks again for all your help. -

-

Hello all,

I, like I assume a lot of newly registered posters are, am a new kid on the chopping block. Although, the word kid doesn't fit since I'm already toying with mid 50's. Anyway, I found the idea of playing with hot metal fasinating and I'm diving in to the world of forging.

First thing first, you need an Anvil. I purchased this just yesterday and feel I did ok although I want some expert opinions. Don't hold back, I can take a punch or two. I'm also currious of its age. I'm not going to ask "What's it worth" because I wouldn't have bought it if I didn't think it was useable. It has a great ring and a real nice bounce. The top surface is as flat as I would suspect an anvil of this age to be with somewhat limited use.

I did purchase a 150# Vulcan anvil earlier and will post those later but I wanted to do this one first. There is an interesting story behind this Vulcan though.

Enough talk, on with the picture show! Thanks for any and all feedback, especially you Thomas. I know you won't hold back.

![20181026_154512_HDR[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/497963413_20181026_154512_HDR1.thumb.jpg.6867a079482d240ac36266853fa054ec.jpg)

![20181026_154438[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/1706132722_20181026_1544381.thumb.jpg.fc6426c8a8579f45b4c0d9b12c413b51.jpg)

![20181026_154358[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/598189603_20181026_1543581.thumb.jpg.81f67f7910310e0e43c76d3dd93dbdfb.jpg)

![20181026_154827[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/1871310272_20181026_1548271.thumb.jpg.3182ed99adb715195094f944cdfd0129.jpg)

![20181026_154630[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/638158706_20181026_1546301.thumb.jpg.a6ca39648c9d3c745403ed840bff920f.jpg)

![20181026_154525[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/968185368_20181026_1545251.thumb.jpg.f3424c11420a51c1d983e190332630b4.jpg)

![20181026_154447[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/1910267435_20181026_1544471.thumb.jpg.32bfdd00bcc83374d69b59affdc40aec.jpg)

![20181026_154339_HDR[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/1259319017_20181026_154339_HDR1.thumb.jpg.0da831bc50397e783827ddd435696457.jpg)

![20181026_154647[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/873733751_20181026_1546471.thumb.jpg.2d6aec12e07e0ef18ac60fa2200242d1.jpg)

![20181026_154542[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/1938293305_20181026_1545421.thumb.jpg.2731e20e137e85ca9cf4e3e67456d029.jpg)

![20181026_154610[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/1042478248_20181026_1546101.thumb.jpg.62a703c29d47495ebed4e2412df30547.jpg)

![20181026_154537[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/491635710_20181026_1545371.thumb.jpg.80e3e2970c9939ba2c4c1b097b8df494.jpg)

![20181026_154431_HDR[1].jpg](https://www.iforgeiron.com/uploads/monthly_2018_10/425582960_20181026_154431_HDR1.thumb.jpg.1889c4bc58fdf91a425a401d96720a13.jpg)

My new aquisition, 351# Peter Wright.

in Anvils, Swage Blocks, and Mandrels

Posted

After doing some info digging and extremely close examination of this anvil it appears that this one hasn't seen any use. There is an ever so slight convex shape to the top plate which by all accounts was Peter Wright's attempt to reduce the swaying effect from heavy use. I wonder if this was a display for a store for most of it's life. You would think they would use a small one as a display.