bomlin

Members-

Posts

176 -

Joined

-

Last visited

Contact Methods

-

Website URL

http://www.xanga.com/bomlin

Converted

-

Location

Land O Lakes, FL

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

The blog can be found at http://bomlin.blogspot.com/ I have not been updating as much as I should have been. I will try and get more information in there in the future but you can look at some of the older posts. Since some of the older photos come from a previous blog site, they may not be as speedy as they should be. I have been wanting to get that stuff moved over before the old site completely shuts down. As far as resources, I will try to put together some of my information. I have quite a bit so I want to be a bit more careful on what I recommend.

-

@RogueRugger. It all depends on what kind of clock you are looking to make. The style I am making is called a "Turret Clock" and they are typically found in church and civic building towers that have clock faces on the outside. It also matters what type of escapement you are using. The escapement is what controls how fast the clock runs. My clock is using what is called a "Verge and Foliot" escapement. These were in use from about the 13th century up through the 17th century. The pendulum was first used in a clock around that time and rapidly replaced the verge and foliot. Are you looking to make a larger clock like what I am working on or smaller clocks meant to be used in a home or office? Something a bit more modern or something historical?

-

Generally, some of the options include plant oils (especially olive oil) and tallow. Plant oils were pretty selective though as some would harden and stick together. The reality is that very little oil is needed if everything is polished up. Probably once a week visit would have been enough to keep it going. Since they would have been visited daily for winding and to reset the time, it was probably just part of the regular visits.

-

The link below is the first arbor (axle) done on the new clock. A reminder that the picture above was from my first attempt in case it is confusing. :)

-

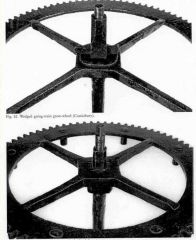

This is a photo of the max progress I made on my first attempt on the clock. The gears in the photos were more of a proof of concept then the actual gears I intended for the clock.

-

When I was researching the clock, I looked at some of the spit jacks to help me understand gear construction. On a trip to Colonial Williamsburg, one of the smiths there was actively working on one. After talking to him a bit, we went back into their break room where they had a 18th century jack that he was using to model his off of. I have probably 20 or so really good photos of it at home. I can send them to you if you like once I get home. If I remember correctly, the smith working on the spit was Ken Schwarz who I believe is the head blacksmith at Williamsburg now. You could also try contacting him.

-

Hey guys, I've been away for a while. Decided that I would start posting some stuff again as I am getting back into blacksmithing. For those that don't know me, I started blacksmithing about 12 years ago to do a dream project of recreating an all forged late medieval/renaissance clock using traditional techniques. I made my first major effort from about 2005-2009. After that time due to stuff in life and job changes, I largely put the blacksmithing aside. I have finally gotten back into it and I am restarting my clock project. When I looked at the frame I made and other parts, I decided that I wanted to start over to clean up my learning mistakes. This past weekend I made the part of the clock know as the verge and foliot. This part swings back and forth and actually causes the ticking of the clock. It serves the same purpose as a pendulum in that it regulates the speed of the clock. So this video shows the new clock frame I made over the past few months as well as how the verge and foliot swing back and forth. It still needs a little bit of work but the tougher parts of the construction of the verge and foliot are done. I still need to add little tabs that engage a gear as well as some work on the ends of the arms. Too much typing, here is the video.

-

-

-

Florida Blacksmithing Convention 2006

Images added to a gallery album owned by bomlin in Members Gallery