-

Posts

39 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Metalsculptingben

-

I have the opportunity to move into an old railroad depot. The floor is is cast concrete, but raised. It is supported by cast concrete beams and concrete post. The floor is two feet thick, but with a crawl space below. Would it be possible to put my LG 100# in there? With that being said does anyone know the force made by my power hammer against the floor?

-

Thanks guys. I have found the glass epoxy bulbs and anchors. That seems like the route to go.

-

Would putting epoxy in the hole before inserting the sleeve anchor be beneficial?

-

I have a client that wants a wall mounted rail. The design that we have talked about will use a decent amount of metal making it quite heavy. Normally I would just make sure that all the wall brackets are on the studs. However, this wall is brick with plaster and I have never mounted to that before. Would I use sleeve anchors in the brick to mount it?

-

Spring Swage Improvement

Metalsculptingben replied to JNewman's topic in Power Hammers, Treadle Hammers, Olivers

I have an idea of what you are talking about, but pictures definitely help. -

25 lb Mayer pics

Metalsculptingben replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

I found that it is best to call. -

25 lb Mayer pics

Metalsculptingben replied to lloe01's topic in Power Hammers, Treadle Hammers, Olivers

Roger Rice helped me loads on making my hammer run correctly. -

Help with a shape

Metalsculptingben replied to Metalsculptingben's topic in Blacksmithing, General Discussion

SmoothBore you are exactly right. Thank you for your input and I'll try to make it out of cardboard now. -

Help with a shape

Metalsculptingben replied to Metalsculptingben's topic in Blacksmithing, General Discussion

-

I am trying to make a shape and I need some help. I want to make a trapezoid, but with the sides curved in. Yesterday I cut four sides to make the trapezoid. They were four inches on the bottom and two inches at the top. Then I placed them in the forge to get them to temperature. Once they were hot, I hammered them into my swage block. After they were cool, I tried to fit them up and nothing fit. Does the original shape need to be more like an hourglass instead of a true trapezoid side?

-

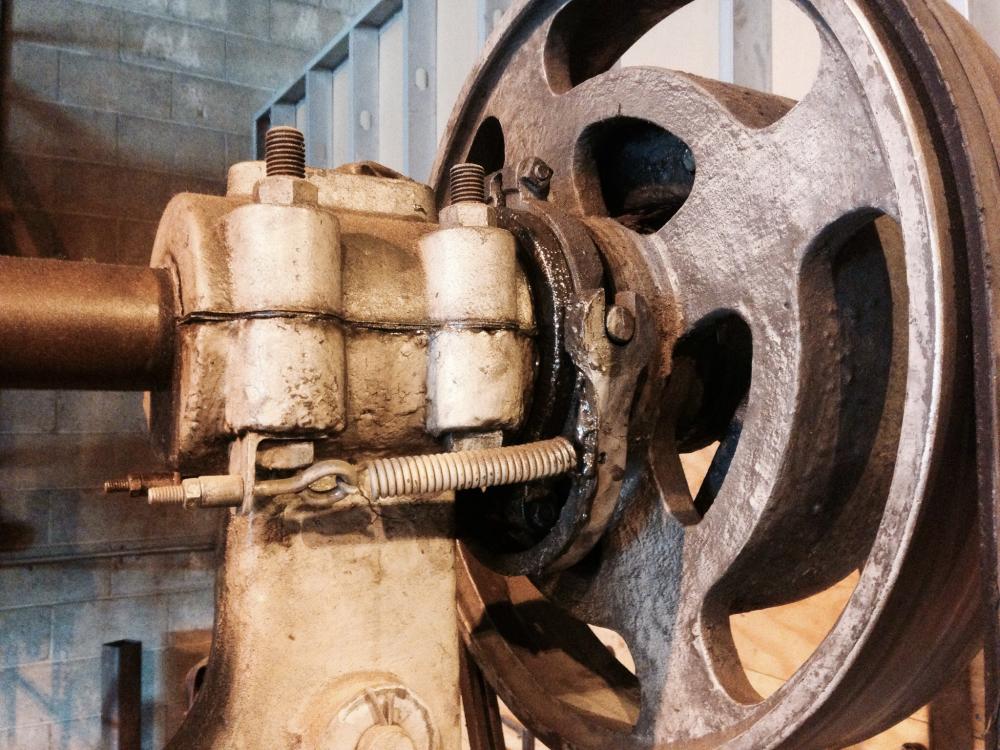

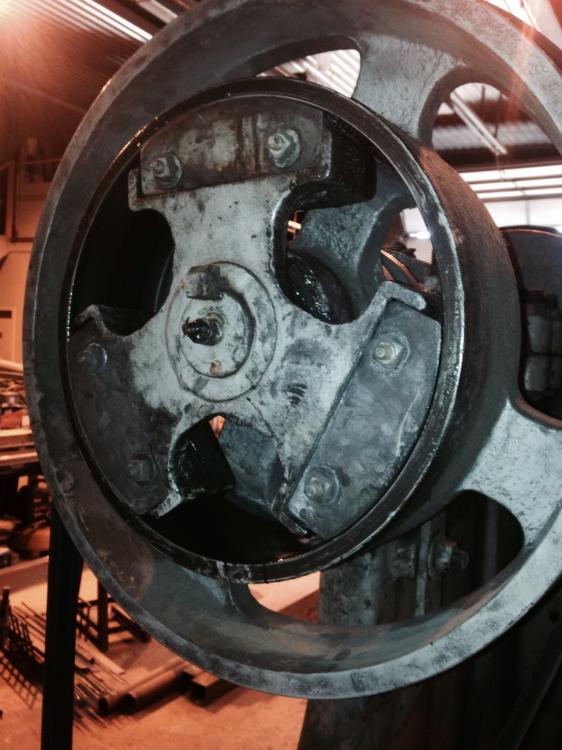

Ok here is a moment of truth. I bought my 100# LG 8 years ago. While owning it I have worked in shops that had power hammer, not mechanical though. So, why should I put wear on mine when I didn't need to. I was just collecting equipment for the day that I would go out on my own. That day came last October and I am not looking back. Once I got my power hammer on a pad I could not get it to work properly. Seeing that I did not have much time on a mechanical hammer, I could not figure out for the life of me why. Yesterday, I figured out the problem. The person that rebuilt the hammer never used it, they just rebuilt it and sold it. I am very grateful of the work they did, but they didn't work the machine to figure out any bugs. So, I noticed yesterday that the brake that they installed wasn't on correctly. Basically it was applying the brake on the side of the wheel while lifting on the top. My machine was trying to go and brake at the same time. When I noticed this, I took the brake off and my LG ran better than it ever has before! I am going to just take it off for now until I know how to install it correctly. I am wondering if anybody could show me their brake system, so I could have a better idea of how they should be?

-

This press makes me drool.

-

"Three items need to be looked at on the friction pulley. Generally only one is in bad shape. The first is the center bearing babbitt that lines the pulley. The constant pull of the belt and rubbing on the shaft have probably worn the hole oversize causing a significant rattle or vibration to be present. An oversize hole will also affect the clutch action." This is a quote from Kern. I am leaning towards this because sometimes I get a rattle that comes and goes as well.

-

42 Ton Uni-hydro

Metalsculptingben replied to Metalsculptingben's topic in Welding/Fab General Discussion

I will most likely replace it with a single phase motor. An expensive lesson learned. -

I recently added a 42-14 Uni-Hydro to my shop. I don't have three phase, so I have been adding a PhazPak to each three phase motor I have, and I haven't had any problems. I got the Uni-Hydro in the shop and I wired in a PR-3 Phazpak. I have noticed a couple things instantly. On heavy loads the motor will cut off. The first real run of the machine was shearing 100 pickets. It took about an hour to do so. When I was done, the motor was smoking. What have I done wrong, and how can I fix it?