-

Posts

202 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by john_zxz

-

-

Hello

I have this leg vise tant I bought yesterday for 80$ CAD. Perfect condition, nothing is missing, 4" jaws. I was able to read St-Paul Works and there is a crown logo. There is also S&W beneath the crown.

I would like to get more info about this company. Around what years did they make these. I think it comes from Minnesota but I'm not sure.

Any help would be much appreciated.

Thanks

-

I just figured out the brand stamped on it. It is a Henry Van Wart Best Scrap warranted anvil. I saw on another anvil the same stamp but more readable.

Thanks for your help anyway. I don't need this anvil. I was only curious of what brand it is.

Thomas, It was when you mentioned Warranted that I was able to do a better research on google. Thanks!

-

This is not my anvil. The pictures are from an ad. I want to know the brand to get a better idea of it's true value before investing on it.

-

Hahaha that would have been awesome then! It is not mine though.

-

Hello everyone

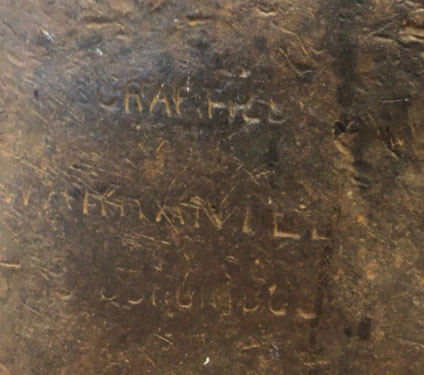

Is there someone who can help me identify the brand of this anvil please?

It looks like the first word is crafted but the rest i can't read it. It is not mine. Only an anvil on an ad.

Thanks

-

Hi, I have forged 1" thick and little over for hardy tools on a 110 lbs anvil. I think that a minimum of 100 lbs would be good for you. Heavier the better but only at a good price. I have a 500 lbs anvil that is waiting for a stand since a year so for now, i take my small anvil. I'm forging all my project on my little 110lbs czech anvil and it's doing very fine. If you can buy a 165 with double horn then go for it as the double horn can be very handy for some pieces. Do you have a picture of the anvil you are looking for?

-

This is my very first commercial made coal forge. It is in very good shape and the blower works fine too.

The forge and the blower are Canadian Blower & Forge Co. Kitchener Ontario.

I bought this forge to make some expositions this summer. It was the perfect size. I'll just clean it up a bit and maybe open the blower to clean it and to put some oil.

-

Oh well nevermind. I misread "round" trip. I just realized that round trip means back and forth... lol English is not my primary language...

-

i am paying $30cdn/50lb bag of good coal, $25/bag for coke, i like the coal better... it is about a 7 hour round trip

I pay 27$/100lbs of coal (bagged in 50lbs). It is south-west of Montreal. It is at H. Riendeau Inc. I think it's less than 7 hours from Norwood. Maybe you could get a try. He said that he tried almost all of the mines in USA and that he found the best quality coal now and stick with the same place. I use this coal an it is very nice. Very little clinkers and easy to control the smoke. Upper Canada Village's blacksmith shop in Morrisburg used to buy their coal from him too... at least, the last time I visited the place.

Where do you take yours?

-

Nice one there. What steel did u use?

-

I tried a bag this summer from profarriersupply (L brand refered me to them as they are their supplier in Canada) I like it. Hot, no smoke, no smell and low clinker for this bag. The size was from 0 to 1". That was the first time I used it and I was surprised with it. I can't say if their coke is consistent in quality and size though.

-

We make a lot of hammer products down here in the South. But I am interested in forging a spring plate onto a face for a tool also. Somewhere in an old manual it was stated that a slot was formed on one piece or the other to help "hold" the other piece steady while performing the forge weld.

I am going to try this next week for one project and then I am going to try placing a little bit of a tack weld (electric) on another. Of course that will be after all the prep cleaning is performed. The tack weld is to only hold the two into a common dimension as the forge weld deforms the two pieces into one, allowing the other material to squish out the crack along the side. Maybe there will be a picture or two taken.

Carry onGreat! I would like to see the result, if you took any pictures of it...

-

Nice! Your hammer looks really good.

-

Thanks all for the comments.

I did not know about the chrome content in the spring... I just took it because I knew it was a hard steel. I learned something new today!

-

Thanks Thomas.

You are right about the mark, I forgot to stamp my initials and the year... I'll do this tomorrow. How could I possibly forgot that... :blink:

I read a similar article for the hammer face in "Blacksmithing Basics for the Homestead" by DeLaronde. I tried to put some spurs in the back of the face to "grip" on the body but they flatenned as soon as I put the hammer head on them... Maybe they were not sharp enough and not raised high enough. I just put the body in fire and when it became yellow I put the high carbon steel near to get the same temperature. Then with my poker and tongs, I placed the face on the body and they stick together just enough to lift the "package" to the anvil. It's the only way I was able to join these 2 pieces together. Before that attempt, I tried the "drop the tongs" method but the face was never hot enough to weld when I arrived to the anvil.

-

For a couple of weeks, I seek the Internet and local shop to find a 2 to 2 1/2 pounds hammer for forging and I wasn't able to find one. All local hammers are 3 pounds and the shipping for a hammer is more than the price itself when I check on blacksmith supply websites. So I decided to give it a go and make myself one. I didn't have any big high carbon steel so I made it the old way. Mild steel body and high carbon steel face. All I had was a piece of 2" round mild steel and spring steel flat bar from a car's suspension.

I slit the eye and then drift it, tapered the pein end and then forge welded the spring piece to the face. It was a really good practice for forge welding. I don't do it very often and I learned much with this hammer. I had diffuculty to reach welding heat on the hammer body and I have tried at least 15 times to do the forge weld. Putting the small face plate on the right place and at the same temperature as the body was real hard. For those of you that say that if your weld did not take after 3 attempt, don't try anymore it is worthless... then it is not true. As long as you don't burn the steel it is okay to continue. I finaly succeeded when I started the forge weld in the fire directly. They stick together when they were at the right temperature and I was able to lift the whole thing to the anvil and set the weld then put it back in fire and do this 2-3 times to make sure the weld was good. Once the weld completed, I forged the face to shape and then I did the hardening in oil and then the tempering. I tempered it to a purple color because I was scared that a missed blow would damage the hammer or the anvil if it was too hard so I feel more safe with purple on the face. I did not tempered the pein as it is mild steel. The handle is red oak.

So far I'm really impressed with this hammer, not because I made it but it happens that it feels very comfortable in my hand. It's like I have nothing in hand, my arm is never tired like with my other hammers. I used to forge with a 3 pound hammer for a long time but now I'm getting the same work done in the same time with a smaller hammer. I can hit faster but with no fatigue. It seems that I found the right balance and weight for me. I was scared of doing all this hard work and then realize that it is not good at all, but it was the inverse totally. Plus, it is very satisfying to forge a good forging hammer like they did in the past.

Give me your impressions guys or your own story with your first hammer, I'm curious to read yours.

-

I'm pretty sure it is fiberglass. I know a blacksmith that did work for movies like 300 and Nouvelle-France (Battle of the brave) and he said to me that almost everything was made of fiberglass. Even the houses!

-

Never heard of a hardy hole in the middle, yea pic would be great.

-

Very nice beast. I like this pattern.

-

If you're using something like A36, it could be anything and not necessarily mild steel.

A36 is a structural grade which means it need to meet certain criteria for strength not for composition so it may have alloying elements that make it air hardening or hot short or just completely unsuitable for forging.

And that may just be a 6 inch section in 5 foot worth of bar or it may be most of a bar.

Since there is a lot of recycle in structural grades they become a crap shoot, sometimes you get a lovely to forge piece, sometimes you get a section that falls apart no matter what you do.

ron

Thanks for the explanation on A36, I didn't know that this steel can be different in composition from batch to another batch.

-

I know this is an old post but I ordered a month ago a Smoosh-O-Matic from Mojave Southern Machine Work too. I waited 2-3 weeks and didn't receive any email for the shipping price, so I wrote them an email and they said that they will get the post office flat rate price in the next days and that they will get back to me with this.... still no email after 2 weeks. Now it's been a month, I ordered the 5th of June and no answer from my email. Is it normal that it is so long for a small object? I think if next week I don't get any answer, I'll want a refund. Paying for something you don't get is frustrating.

P.Bedard, did you finaly receive your blacksmith helper? If so, after how many month or weeks?

Thanks

-

Aww... Sorry for your loss Pete. I know it's tough to live with at the beginning but they are young and they will get through it. How old was she? My 2 cousins (same age range) lost their mom recently too and they are getting better and better. It was hard but now I can see a smile on their face, that means they are in peace now. I hope you the same for your family.

-

I like them. Well executed! They look as ancient as the chest itself.

-

The steel is 44W (A36 for US I think?). Is there any issue with working it at yellow color? This is the only mild steel they sell at my local supplier and I'm a total newbie with the differences in mild steels.

It think it may be because of my new light bulb (fluo compact) I must have misread the color of the steel.

If I grind it to remove enough of the cracks it will be too thin, so I'll cut the bad part and weld a new rein (the jaw is still in good state)

Wilkinson's anvil info needed

in Anvil Reviews by brand

Posted

Hello guys,

My friend have this Wilkinson's anvil with markings on it but I can't read them all. I see on one side:

(disappeared Wilkinson's)

Emblem

Queen's

Dudley

And on the other side I think I can read:

Patent

Solid

(R or B)un & En(I or T) ------ This is the part that I can't read.

Does any of you know what it can be written please?

Thanks