Savlaka

Members-

Posts

57 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Savlaka

-

What did you do in the shop today?

Savlaka replied to Mark Ling's topic in Blacksmithing, General Discussion

I have 1117 in hex bar, and some 1215... along with some 1141/44. I have seen 1018, 1045, 4140, not including the Lead bearing steels (like 12L14) from one of the places I get metal. -

thanks y'all, I thought it was the simplest method of both storing and being able to feed the forge (or grill). while the studies I read show autoignition of charcoal does happen, normally it requires a very large pile (I was seeing #'s in the range of 20-50 cubic meters), and it needs to get soaked. the autoignition happens at the interface of the dry and partially wet (drying out) charcoal. usually more of an issue for industrial situations... But even with that, I tried to ensure that there was some airflow available from the sides. this bunkers sides are not fitted super tight, the fence pickets were left as they were and just placed close and screwed into place. on the other hand I knew the top would get rain spray on occasion so the top is multiple layers in alternating directions and the edges were jointed to make it fit tightly. then glued and screwed together to make a sort of plywood. I did not find any water inside after the afternoon rainstorm despite the top being wet from spray.

-

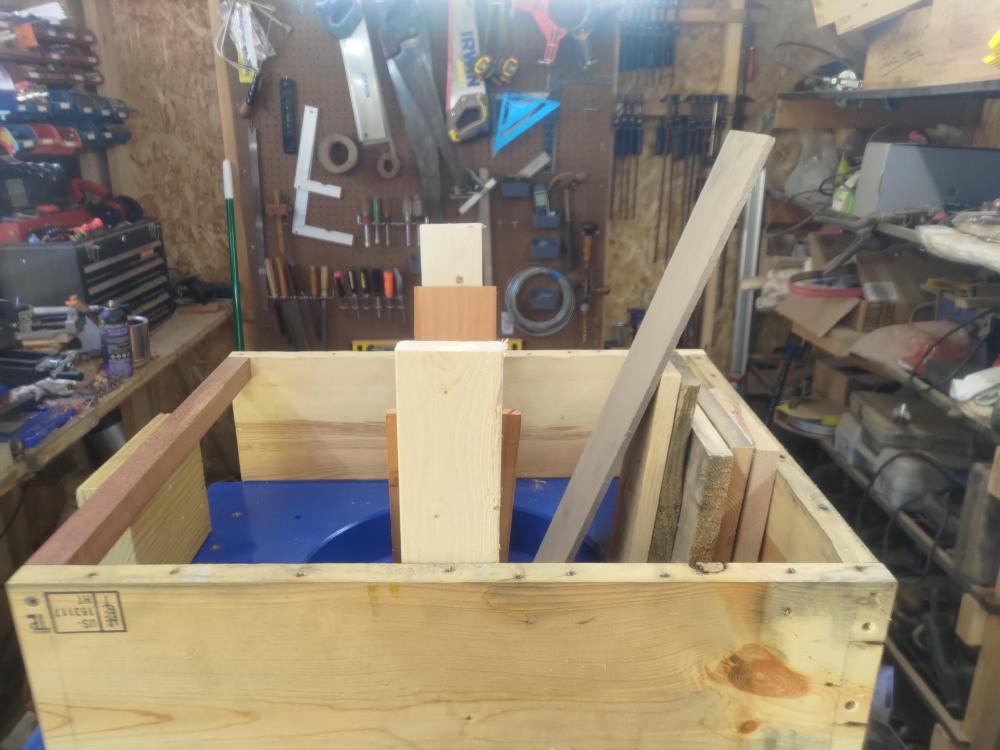

I got the rain cap on, lucky for me the day before it started raining again. and a bit of flashing (not done in the photos) seems to be enough to keep out the majority of the water during the rain. And then I moved over to the other part of this project, the charcoal bunker. I made the charcoal bunker from old fence parts, and a few small cut-off's from making shelves. this design allows me to just take a scoop of charcoal out the bottom and dump it into the forge as I need more fuel. I break the big chunks coming out of the bags down to size and then dump it into the bin., and my guesstimate on total capacity is 250+lbs of 1-2" charcoal pieces - at least. 50lbs just barely covered the sloped section. now I can pick up charcoal when it goes on sale and not worry too much about storing the bags somewhere.

-

Irondragon - I was cranking on it much more than needed to make as many fire fleas as I could to see how it would handle them. Jason - Thanks. The hood is completely over the forge but is offset to the rear a bit. Almost there... I got the rain cap for the chimney started, I need to make the mounting legs for it - it'll bolt onto the top of the chimney using the 5/16" threaded holes already there. All of the major work on the hood itself is done. the front of the baseplate decided to warp some when I fitted the front panels on... some percussive persuasion convinced it to go back to where I wanted it :). I did use some of the red paint... just only on the inside. it's only for rust prevention I know it'll be black eventually. I got the rest of the metal stripped and clean and repainted it's a semi metallic grey. once it was dry enough to move I put it in place. after these photos were taken I got the roof panels cut and put back in place, though I still need to make some flashing to get it mostly watertight. I also still have a bit of sheet metal work to do for the rain guard... I'm not trying to get all of this sealed up 100% waterproof just to block most of anything that makes it to the forge.

-

So I got some more work done on the hood. I cut the opening out and made the top extensions for the opening, I have the side panels roughly cut, I'll fit them after I weld the base frame to the tank and cut out the front section of the frame to fit. But I decided I needed to give this design a quick test to make sure everything was going to work the way I wanted. So I dumped in some 1/2 rotted pine sapwood and the dusty dregs from a bag of charcoal to make the most smoke and fire fleas I could... I definitely need the extension (perhaps visor is a better term?) on the top of the opening - without it I was only containing about 60% of the smoke and 75% of the fire fleas. But with just that top piece it worked almost perfectly - at least 90% of the smoke and better than that for the fire fleas. I'll be working on the roof panels and chimney cap later, and once it cools off again I'll get to welding up the parts. The final bit will be the rain guards and painting all of it... Though I need to pick up some more high temp paints all I have left is red, don't think I want this thing bright red...

-

I've been working on the better hood design. - Sorry Frosty not a side draft, but for my needs I think a full hood will be better for my installation. the roof is only about 4 foot above the forge table and next to a main beam, so I have to think about radiant heat management. I've got the base frame partly assembled, and the tank cut to size. and I've started fitting the remnants of the old hood as a rain guard for the table - while it's under the roof it's right at the edge and will get spray and sometimes even direct rain depending on the wind. I still need to cut and build the front opening, I'll start on that tomorrow most likely. I found some metal to make the chimney from some metal table braces they are a bit under 7 foot long 6" wide made of 1/8" steel. trimmed and fitted up they will give me a solid (if a bit heavy) 6x6x37" square tube, currently I have the tube just tacked together, I'll run solid welds once I've got all the upper mounting decided on. I made a square mount on the top of the tank from some 2" 3/16" bar stock, and the chimney bolts onto that using some stainless 5/16" bolts. I still need to design and build a Rain cap for it, and finish cutting the roof panels to fit.

-

What did you do in the shop today?

Savlaka replied to Mark Ling's topic in Blacksmithing, General Discussion

Made some gate hinges today. Still gotta make the handle and latch, but these seem to work good. The strap portion is made from a 3/8 wall 1026 DOM tubing. 2x 1" sections I cut, flattened, and shaped before welding on another smaller 11/16" ID tube for the hinge point. 1026 DOM tubing is nice since I can be hardened somewhat to increase it's resistance to bending. - not a lot but noticably springy after treatment... The hinge pin plates are entirely fabricated with the MiG welder, mild steel plates and a section of 1060 11/16” rod. All the parts were cleaned up and then tempered / colored to get that nice somewhat dark bronzy color. And I sealed them with a clear enamel paint. On the subject of forums and asking for information: I looked a a number of different forums before deciding on this one. All forums have their spats of "experts" with different ways of doing something, that's one thing you can't get away from. It happens in person as well as online... One of the reasons I decided on I forge iron vs others is that their is a wide variety of smiths on here. With that you'll inevitably end up with some pissing contests, But there's likely someone who is closer to your style of work, or is easier for you to understand their methods - and that can be priceless... A Method, process or style one person does for getting a project done might be viewed as backwards by another person, but if it gets the results that they are looking for then that's the right method for them - Even if their methods are technically inferior in some way. There's some chasing "perfection" and others just after "Good enough" neither are right or wrong, just different goals. -

Irondragon- the dragons breath from this ribbon burner forge is quite small- I've worked to keep it tuned so it only runs just on the rich side so I don't scale things up inside... at welding heat I get 6-7" at most, and at normal operating temps I only get 3-4" - and this is with the doors only open an inch or so, if they are fully open 1/2 that distance or less is there. also it Immediately is heading Up and away from the porch so a small section that's insulated like the forge but not under the burners would allow me to Low heat items a lot easier than trying to hold them in just the right spot to keep it in the flames.

-

I was doing some yard cleanup and rearranging of stuff, and I found I still had my old compressor. I'd replaced it when it's motor died and set it outside the fence to deal with later and it seems I promptly forgot it was there. after cutting the tank off just below the handles i have a 16" dia x about 18" tall section I can use to make a better hood... now I just have to come up with something to make the chimney from.

-

What did you do in the shop today?

Savlaka replied to Mark Ling's topic in Blacksmithing, General Discussion

White fox- that's a nice tomahawk,I like the Damascus plug I don't see that a lot .. one of these days I should probably try my hand at an axe, hatchet, or tomahawk. Wandering rogue- looks to be a good knife you've got there. I understand about finding the best heat treatment method for something, I don't have a heat treatment oven, so it's often a bit of a game of test and see to figure out what works best for me and my tools. Even if you know the exact prescribed method for a given steel, getting those results with the equipment you have usually requires a bit of testing. -

So I figured I'd come back here after about a year of use and pass on what I've liked or not, and what worked and what didn't. I'll start with the burners: I've played with the tuning and hole count for the burners a few times, but it was all basically fine tuning and getting the best efficiency I could... Both burners are holding up VERY well and working great. If I built them again I'd make the slots a bit shorter as they're definitely longer than needed. And I would cast "ears" on the sides of the ribbon burner blocks instead of using the ceramic board strips to seal up the top. The forge itself: The size is decent and the length hasn't really been needed often but it's definitely nice to have, I've found I can run both sides and put different projects in each side which has been useful for lots of small projects that lose their heat quickly. And for heating a big item while working on a few small items. If I was doing it again I'd have gone to 5x5 instead of 4x4.5, the tiny bit of extra size would have not done much to effect the ability of these burners to heat the forge, but would allow a little more flexibility in work size. I've learned that the center baffle was basically a waste of effort. If the back doors are closed time to heat up to normal operation is basically identical. Though because Florida is so humid I typically need to run both sides at a low output to boil off the moisture the first time I light the forge for the day anyway. If I don't the unused burner will fill with water from the steam. At this point I don't use it at all, I just leave the T shaped plug in place. The tabcast 94 is awesome as a forge floor, it's basically been totally impervious to anything I've done, it ignores Flux's and scraping steel against it. Though I would do a better job casting it smooth and flat the next time I need to do it. The heat guard refractory and the satanite I used as surface coatings haven't faired very well. Where they are on ceramic wool they did well, but they eventually just crack and peel off the tabcast walls. I should have built a "porch" on both sides, and it should have been 2x the size of the one I did. I also should have built a short insulated "dead" section on each end of the forge (a 3-4" or so section not under the burners). This would give me a bit of a gradient for heating things up to lower heats - like temper coloring an item. As it's built anything inside the door lines will get to full heat after a bit. Overall this forge build has done very well for me, especially in the last few months it's been run for a few hours at least a few (3-5) times a week, and is holding up well.

-

What did you do in the shop today?

Savlaka replied to Mark Ling's topic in Blacksmithing, General Discussion

wirerabbit- thanks, it's not entirely unwelded I just didn't squish it to a full round. I welded about 1 inch of the ends solid, then twisted it all and did a light weld for a few inches on each side of where I wanted the "grip" and then untwisted the handle section. Though nowadays I do cheat a little, I tack weld the ends of the rods with my mig welder to keep it all in place while I get things started. for flux I use common borax like you get from the supermarkets laundry section (20 mule team brand in my case). But I also keep lab grade boric acid for when I need something with a stronger cleaning action... I'd like to get some powdered metal to add in, but haven't gotten around to it. You can use all kinds of things as flux, powdered glass, fine sand, and plenty of other things... But if your forge is running slightly on the fuel rich side and you clean everything well before it goes in you can weld without flux... But if it doesn't take the first try usually you gotta reclean all the scale to try again - at least in my experience -

What did you do in the shop today?

Savlaka replied to Mark Ling's topic in Blacksmithing, General Discussion

Mostly been cleaning up and getting things ready for the next projects, but I finished up a bigger straight peen hammer - this ones 2.25lbs. And I made a simple bending fork for my hardy hole - this one is 3/4dia x 3/4 gap. Not perfect but it works. And I made a fire tool for my charcoal forge, basket handle with a simple hook on the end... And a quick rack for a pair of firebricks... JHCC- I use the same stuff for my punch lube, messy but it works well. -

Yep, the "hood" is quite janky ... I've been looking for metal buckets for over a year now, nothing seems to still come in them. The shop I used to work at got their grease, specific oils and solvents in 5 gallon plastic buckets. We'd actually had to replace our air grease bucket since it didn't work with the plastic buckets... I checked at paint and auto shops and even there basically everything comes in plastics now, only a few types of solvents didn't and they were normally 1 gallon cans or 35 and 55 gal drums that they wouldn't sell or give away. Everyone in my neighborhood is on a well system so there's a good chance someone will have a failed pressure tank around. The biggest issue is the "chimney" is too small and not mounted in the right way, finding anything better will be a bit of a challenge, there's nothing in the way of fireplace, wood stove, or similar supplies readily available down here. I'm sure you can go into your local home center and find basic stuff for all of those kind of items, but none of that is stocked in Florida - it's all special order, at best. As to a passthrough, Nope. If I needed to I can place work on diagonal across the forge. But realistically I'd just heat a long bar in the gas forge. I don't do the fence, window and railing type work so it's not too likely I'll have a need for anything like that. This isn't the kind of forge many would build, it's bigger than is economic to run all the time, and it isn't configured the best for general work. But it'll do exactly what I need it to and so far out of pocket I've only spent about $20. Everything but the sand and clay was stuff I had laying around - left overs from other projects or salvage materials...

-

I Got the air supply and ash dump fitted up, and gave it a test burn... Heated up a 1.25" bar ok, wasn't really trying too do more than test things out and give the fill an initial baking... in the photo It's in full daylight so it only looks a bit reddish orange. The hood mostly works, but I'll definitely be building something better when I can find the materials to do so. It fully works as the heat shield I wanted, less so for the dust and sparks. Though of course the wind had to start blowing directly into the chimney opening... I'm thinking an old water pressure or compressor tank would work.

-

Jason- I do have a chimney on there, it's not as big as I'd like, as I was running out of sheet metal. It's final size came out to 2.5 x 7.5 x 30" that gets it a bit above the roof. Eventually I'll probably build a better hood and a 6-8" diameter chimney for it, but this is what I have on hand at the moment.

-

This morning saw me fitting the parts for the front of the forge in place and packing the clay/sand filler into shape. I used a section of the bag the sand came in and some rounds I cut out for the shape of the firepot... I was only after a rough form and did the final packing by hand using a hunk of 2x2 as a packing stick. Took me about 125lbs of fill in the end, I shaped the work entryway to accept firebricks so I could adjust the depth of the fire and work piece as needed. At it's lowest I have just under 5" of depth to the grill, and with 2 bricks I can get 7.5".

-

I've gotten a bit of work done on this project. I've put on the wood rim, and legs, and moved it into place in the pole barn, I have a part to make for the front still but I'm still working out exactly how I want it to be shaped. I have a section of thin sheet metal from the casing of a water heater that I'm turning into a Heatshield / hood and smokestack. it's almost too thin for my welder to work, and after trying for way too long I finished up with sheet metal screws. this is not a full hood since I just didn't have enough of the material to do that... and I was really mostly after keeping stray rain spray out (its still under the roof, but right at the end) and giving a bit of a heatshield to the post and the fence that are close by. I'm also working out exactly how the fill will be mixed up this tub is currently about 15lb of clay and 50lbs of all purpose sand, lightly wetted and mixed. I'm going to let it set overnight then check it's consistency, I'm looking for it to be able to be formed into a ball, and not crumble when I roll it between my hands but still be as Dry as possible. I think that will let me pack it Very hard and let it keep it's form well. I may add some ashes to the mix since I plan to smoke some meat this weekend and I'll have some to use then...

-

Wirerabbit- I actually started with charcoal. my first "forge" was a dug out trench in the ground with a side blast done with a small electric blower fan through a 1" pipe. me and a friend in high school built it and tried to learn how to smith in a lot next to my house, our "anvil" was a Press block from a truck repair shop's old hydraulic press a 2.5 x 6 x 14" hunk of steel we bolted to a stump... it was a few years later when I had my own house that I built my first gas forge. as to being alterable - the only things "fixed" in place right now is the parts I welded. I expect to need to play with things to get it all to work the way I need it to... i'm only using cat litter / floor sweep and sand at first and all the wood is "reclaimed" lumber and is only screwed together nothing fancy... Frosty- Yeah, I assumed that this thing would be a charcoal pig... and I actually already read through the JABOD thread, if this was to be my main forge I'd be aiming for about 1/2 the size... I'll probably only fire this thing up once a month or so in the long run... The exact size that I make the pot is still to be determined, but after reading through a few old papers on charcoal vs coal forge design and looking at the offerings of the (fairly few) commercially available forge designs that list as designed to use charcoal what I'd seen is that I'll need at least 1-2 inches of space wider than the largest items I want to heat - so 8-10" is the size I'd need in the smallest dimension. I was looking at 9x12 at 8 inches deep total... the 8 inches deep was coming from many, many places where smiths built 4-5" deep (like most commercially made Coal forges are) and needed to add bricks to get the depth to heat stock over 2-3" when using charcoal. The biggest single item I have to do is 5.5dia x 2.5" but I need to heat a 3.25dia x 3" piece (both are 1045 steel) at the same time as these are to be forge welded together, then some shaping and a simple heat treatment to harden the finished item. Though I do hear you, and I'll aim on the smaller end of the size range I've researched. IronDragon- I have a basic hand crank blower I intend to use for this, nothing great mind you but it should be sufficient for this project. that and that old brake hub is actually why I looked a bottom blast for this project since those things are just taking up space at the moment, be nice to find a use for them both.

-

so I've decided I want to build a charcoal forge to expand my options for projects. I can currently heat anything up to about 3" or so in diameter and basically any straight length I want in my propane forge, and about 85-90% of all the projects I've got planned or likely to want to do can be done in my propane forge, so this project is to do those 10-15% of things I just cannot fit in the gas forge's 4.5x4x24" interior... also I'm trying to do this for As little out of pocket as I can, using whatever I can lay my hands on around the shop. this means I'm not aiming for everyday use efficiency, I'm after something to handle bulky or large items. And after looking through a LOT of different info on solid fuel forges this is what I've come up with: I started with a brake hub form an old M149 water buffalo and a hunk of old metal shelving that I cut and welded together. then fitted a 2x3 frame under the edge of the shelf section. and finally welded on a 2.5 to 2.25 exhaust pipe adaptor into the bottom for the air piping to fit to. The metal was painted to prevent rusting. next I Made a grill type air diffuser, the ring is a hunk 1/2" car spring I made into a ring to fit the bearing seat lip. Then I welded on 3/8 bars (well 13/32") spaced 3/8" apart. this lets me have a removeable grill in case I ever need to replace it. next I attached wooden sides to it to extend the depth so I can form the firepot tall enough and big enough to fit the types of projects I intend to use this for. the stacked wood is me trying to decide how I want to shape the firepot and if I've got enough depth... Right now it's 8" from the grill to the top of the wood sides. and I'm looking at a firepot in the range of 9-11" x 12-14" and between 8 to 10" deep. I think that will get me a fire big enough to heat up the biggest item I need to do (a 5.5" round 2.5" thick). I intend to add about a 2" rim to widen the sides to match the distance from center that I have at the back. I'll be filling the box in with a sand (2/3) and clay mix (1/3) to build the actual firepot. the clay will be bentonite from floor dry / cat litter, sand I have easy access to, it's Florida that's all we have for "soil", though I may buy a few bags to ensure its not limestone sand. I tried to get some fireclay but none of the possible suppliers around here carry it. One told me they could get it, but as a special order I'd have to buy 10 bags- yeah that's not happening. I do have about 10lbs of Satenite sitting around and wonder if I could use it as a top coat over the sand/ clay base at least in and around the firepot. I'll update things as I get to them.

-

What did you do in the shop today?

Savlaka replied to Mark Ling's topic in Blacksmithing, General Discussion

Goods - that's a nice pile of cutting tools, they are very consistent in finished size and style. I especially like how that middle tomahawk's handle came out. JLP- Thanks - though honestly it was starting to get funny when the second person was replying to you about the post, I was wondering how far it'd go . I looked at doing a solid one, but since I was planning on putting it down below my anvils I figured it'd just get filled with scale flakes eventually. for longevity the two plates I drilled are both hardwoods. the only pine is the plywood on the bottom and the standoff's that should help it last a bit... but it was just scraps anyway. Chad- those are some great scoops! -

What did you do in the shop today?

Savlaka replied to Mark Ling's topic in Blacksmithing, General Discussion

M3F- looks like a great workshop you've got going there. Wirerabbit- those Tongs look good to me, they'll hold the size they are supposed to and that's what really matters. I've been Doing more tooling and some odds and ends. today was the first cold day we've had this year (58 degrees - yeah it's SW Florida) so I spent most of the day out there working on stuff... made a punch holder that I mounted to the side of my anvil stands. just scrap wood I had in the wood shop. then I made a few punches and such, two for me - a square face center punch from reclaimed car spring, and a slitting / drift tool for 1/8-1/4"x 9/16" wide slots from 1060. the other two for are for a friend of mine, two center punches one med (1060 and a 90 degree point) one small (4140 and an 82 degree point). last I made a 1.5lb ball peen style hammer. it's 4130 and the flat face is Octagon and the ball was made more spherical than the commercial ones I have, as I think this will work better for my uses... all five of these are still waiting on their heat treating, I'll probably do them and anything else I might get done towards the end of the week. -

What did you do in the shop today?

Savlaka replied to Mark Ling's topic in Blacksmithing, General Discussion

Chad J.- on the round center wings just hot brush it with a brass brush and it'd definitely be a dead ringer for the golden snitch . As for myself, I made a swage bar for my anvil... It's a bit ugly but, should be functional till I can come up with something better. I made it from the center bar of a 7 ton jack stand it's an "I" shaped bar made of some kind of cast medium carbon steel (that's my best guess). It was 1.5" wide and about 2.5" tall with the center of the "I" being about 3/4" so I filled in the center with a few lbs of 7018 rods to give it a bit more mass to work with, and I cut V's into it to reduce the amount of forming I had to do by hand - and act as guides. I put rounds in of 3/8, 1/2, 5/8, 3/4, and 1" and two 90 degree V's. I was after 3/4” and 1-1/4” but I screwed up the smaller one at first and ended up going to 1" to fix it. I used various stock I had on hand as the fullers to pound in the depressions. Mostly med carbon bars I hardened to resist deforming under the hammer. And when I was done I did a partial hardening in slow oil... I didn't really do any Tempering, closest was basically me welding on bigger fillets into the hardie shank, and filling some of the gaps on the bottom side - running 165A beads got the thing showing at least straw all over it... My tests on sample pieces showed it would fully harden in water or parks 50 and get glass hard and brittle, but it would get to around 40-45 in the slowest oil I have I and stayed quite tough like that - barely bent a 3/16” strip with a hammer in the vice without any kind of tempering. -

What did you do in the shop today?

Savlaka replied to Mark Ling's topic in Blacksmithing, General Discussion

jlpservicesinc, Thanks - I asked her what knife she liked the best out of all the cheapies she had and modeled the blade after that one, though I went with a very different handle design. as to the meet - I honestly don't know anything about it, I'm not a member of any of the groups / clubs down here. I'll probably join one eventually I just haven't got around to it. LOL... Yeah Frosty it was a bit of work, the hardest part of the holder was trying to get the twists right, I eventually gave up on one of them. It seems I somehow stretched one of the 4 legs of the twist slightly longer than the others and I just couldn't seem to get it even after that. Though it was one of the tongs that took the most time, it has Asymmetric jaws one side is a large V and the other is a smaller V with teeth - I made it to fit a wide range of square, flat and round as a filler tong for specific sized ones. I've run into a number of times I needed a different sized tong due to the forging I'd done on an item... it fits 1-1/4" to 3/4" very well it'll go down to 1/2" and up to 1-1/2" if i don't need a perfect fit and it'll hold flat bars from 3/4" up to 1.5". I made the two jaws from some 3/4" 1117 hex bar and as I don't have any kind of swedge block making the larger V Jaw on the edge of the anvil was a real pain. that's actually one of my current projects is a hardy swedge block and handheld top tools for it. -

What did you do in the shop today?

Savlaka replied to Mark Ling's topic in Blacksmithing, General Discussion

Along with some more tongs and hand tools I made a paper towel holder for our kitchen, one of the twists didn't come out all that well, but they're inside the towel roll most of the time... It functions well and the Girlfriend liked it so it works. I did my first stainless steel blade, up till now I've only worked with carbon and Tool steels for blades. It's a small kitchen knife for my Girlfriend's mom. When I made dinner over at their place there wasn't a single decent blade in the place (nor a sharp one). Also first time dealing with air hardening steel - 440c from 5/8” round bar, and honestly that stuff is harder to shape than the 52100 I often use.