railingspotter

Members-

Posts

11 -

Joined

-

Last visited

Profile Information

-

Location

Edinburgh

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

@BIGGUNDOCTOR no the cast iron is the spear shaped spindle+finial units that are one continous vertical unit. But they've been slotted into the holes in the horizontal steel rail, and then each (oversized) hole has been welded shut, filling the gap and forming a joint with each spindle. If we could ditch the rail and start again that'd be ideal, as the spindles aren't even fixed in the stone yet. But the only way to do that would be hacking away at the welds joining each spindle to each rail hole. That would cause a lot of damage to the spindles and it'd be very time consuming anyway. See pic. @Stash you're right in a sense and tbh I want to avoid blame anyway. It's my job so the buck stops with me and if I want a fix I have to chalk it up to experience & pay for it. My aim has always just been to replicate the Victorian originals as closely as possible (including the gate), which is just why I'm struggling with this one. They just didn't do it this way unfortunately (and I can see why, as personally I think the finials look best as 'toppings' rather than continous elements of the spindle).

-

biggundoctor That isn't possible sadly. Each spindle has been welded in place in its respective hole in the 20mm rail. You could cut off the rail at either end but you'd then have to cut into each hole to separate it from each spindle. That'd then cause damage in the spindles that would be visible when you eventually drop them down. We tried cutting out the welding on one spindle but it's deep into the 20mm hole - just not budging. (The spindles aren't fixed to the stone yet btw) George N. M. I hear ya. For sure no one else would notice the mistake, but it's all I see when I look at them now. I know my personality & I feel like the money would be well spent to remove the mental irritation! You're not wrong though... the best fix would be mind over matter.

-

I don't understand - the horizontal rail is welded to each spindle. If he chopped off the rail, he'd be taking 20mm of each spindle with it. Then he'd have to lower the rail fixing accordingly & there'd still be the alignment issue - i.e. making sure that each finial is positioned perfectly above each vertical (correct placement & correct angle - they're not standing perfectly vertical - the spindles seem to slope slightly down with the road, albeit at a much shallower angle)

-

@Purple Bullet Sorry yes it's one continuous vertical - the finial & spindle came together as one unit, all cast iron. The rail is steel. @BIGGUNDOCTOR I don't think removing the rail would achieve anything as the spindles would still need to be separated from the finials (as just clarified, they're one continuous vertical). Thanks for walking me through the process though - that explains a lot!

-

Take your points @Frosty, but in my defence I'm a customer - not a blacksmith - and my only mistake here was assuming that they'd opt for the *standard* height. I literally can't find any other examples of such a large gap between the rail and the finial - and you won't be able to either if you look online. They've made a bad choice and I'm just trying to work with them to fix it, even at my own expense. This wasn't a subjective judgment though - there's a single, correct, standard height for these finials to sit (visible all over the Victorian city I live in - Edinburgh) and they've just not followed it. Should I have double checked the height to rule out any possibility of a mistake being made? Yes. Am I the one who actually made the mistake? No. This is an objective restoration project - not a custom project guided by personal preference. But I'm not interested in a fight so I just want to move forward. From the replies & wider reading it feels like this is definitely fixable, but the quality of the repair will vary based on methods used & time taken. That's why I'm biting the bullet & I'm willing to spend more - even though I obviously feel a bit annoyed at their poor judgment. My big concern is alignment. I find it hard to see how they will align each finial perfectly above each spindle (it's complicated by the fact I'm on a hill, and the coping wall / rail slopes with the road). JHCC mentioned using a board and I've also seen a post-to-post string mentioned elsewhere. There's 50 spindles in total... does anyone have an opinion on how long it'd take to execute this repair to a high standard? Is tacking in-place an option before the final weld? And does the weld set solid immediately or can it be adjusted slightly while cooling if necessary?

-

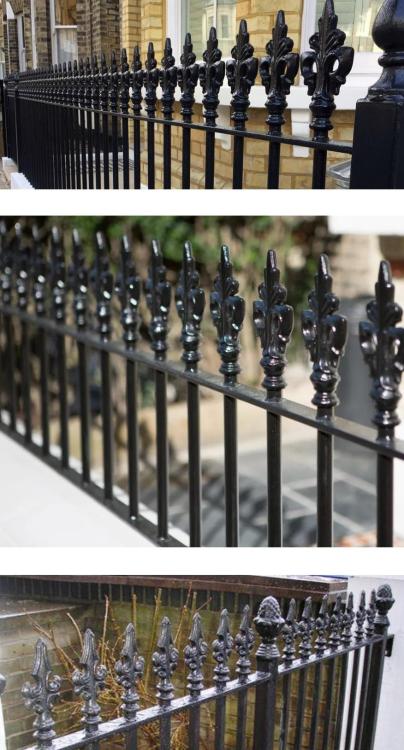

Hello - I'm having some cast iron spindles installed in my front garden and they've been welded at the wrong height, so I need to decide what to do. Can anyone offer their opinion? The first attached picture shows the issue. The spindle finial bottoms sit about 55mm above the rail, and the tops are perfectly level with the (original Victorian) post finial. At first I didn't notice anyone wrong with this, but now I can see that the spindle finials usually sit much closer (~25mm) to the rail & a step below the post finials (see second attached pic for examples). I didn't specify the height before welding & my blacksmith is being patient with me, so I'm not annoyed really. I just want to make the right call now - before the gate is forged at before I paint them etc. I have just two options: do nothing; or have the finials cut off and rewelded at the correct height. (Removing the spindles isn't an option as they're welded solidly to the rail, albeit not fixed to the coping stone yet.) My blacksmith is happy to do either, but he's warned me that because these are cast iron the weld won't be as strong as the original base metal (seems to be true: https://www.twi-global.com/technical-knowledge/faqs/can-you-weld-cast-iron ). He couldn't give a precise estimate for the strength, but said it might be about 70%. Basically he said snapping off is a potential concern if they were hit with heavy force (though he added that the same holds for cast iron generally, as it's quite brittle). Separately, I guess there's also a risk of slight misalignment when the finials are re-attached (there's 60 of them!) What would you do? How concerned would you be about reduced strength Vs aesthetics? I can be a bit OCD so I'll find it hard to 'unsee' what I now know is a mistake in the placement. And I really did want these to look as original as possible. But at the same time, I'm worried about pursuing a fix that actually causes more problems... I'm all ears if anyone can offer an opinion! Cheers

-

Wow, so I walked past these wrought iron gates dozens of times when I lived in London https://en.wikipedia.org/wiki/Jean_Tijou#/media/File:Gates_to_Kensington_Palace_(24156107225).jpg Great to know who made them! The "heavy massive look" sounds right for the surviving cast iron railings in Edinburgh's late Victorian suburbs. I'd say 90% of these railings are gone thanks to the war effort, but they were left in situ around basement flats & other areas where removal would be dangerous for residents. (They must indeed be brittle, as you quite often see finials snapped off.) In the posher centre of the city there's some real monsters, my personal favourite (wrought?): https://www.google.co.uk/maps/@55.9482095,-3.1919821,3a,21.1y,243.89h,86.94t/data=!3m7!1e1!3m5!1s1nQKOx4k0H6FehpRSUdncQ!2e0!6shttps:%2F%2Fstreetviewpixels-pa.googleapis.com%2Fv1%2Fthumbnail%3Fpanoid%3D1nQKOx4k0H6FehpRSUdncQ%26cb_client%3Dsearch.revgeo_and_fetch.gps%26w%3D96%26h%3D64%26yaw%3D148.41814%26pitch%3D0%26thumbfov%3D100!7i16384!8i8192 Anyway a simple but substantial fleur design will fit perfectly in my area. I definitely want the cast iron 'look', and it sounds like that should be achievable with either material - cast iron or galvanised steel - just as long as the dimensions are correct & I opt for paint & find reputable tradesmen. Will be interesting to see if there's a big price difference between the two.

-

Haha well I'm 38 and if I'm going to spend a few grand on this then I certainly want them to outlive me! Edinburgh is full of so many stunning railings that have lasted 200 years. I'd just like my railings to be consistent with them (if not as grand) and to look like good-quality, long-lasting replicas. There's a lot of cheap tat in this city as well...

-

ThomasPowers: I live in Edinburgh so crappy weather is the norm, but it sounds like I might be under-estimating steel. Re the setting material I hadn't thought about this & as long as the modern resins are a good substitute I have no problem with them (although https://www.buildingconservation.com/articles/lead-fixing-ironwork/lead-fixing-ironwork.htm warns that it's a "relatively recent technology ... and there may be difficulties associated with this system which have yet to come to light"). Asking a mason to do the mounting sounds like an excellent idea. I already have one coming over to quote for re-rendering my sandstone facade (butchered in the '70s) - maybe he'll fancy an extra job Glenn: It sounds like you're a bigger fan of painting then, even for steel? That suits me fine as I had presumed (maybe wrongly) that paint will look less 'polished' than powdercoating, which is great as the imperfections / lumpiness make it look more authentic. I'm very willing to apply a new coat every few years as required - seems well worth the effort to keep it tiptop. Thank you both for replying

-

railingspotter joined the community

-

Hi - I'm looking to get period-style garden railings installed and I want to see if anyone can tell me the truth about this... I absolutely love original Victorian railings. And I hate how almost all modern replacements use a lower rail to link up the spindles, instead of having each one individually set into the coving stone. It just screams "not as good as it used to be"! I've asked two blacksmiths if they'll set the rails individually and both tried to convince me it's not worth it / not structurally beneficial. Really?? Surely the railings are much, much stronger when there's 30-odd fixings instead of just 3 along a stretch of wall? And if I notice the aesthetic difference, then surely others do too? Am I just being a difficult customer or am I right to hold my ground with this? Be honest as you like (And while I'm at it... will powder coated galvanised steel really "last a lifetime" like I've been told? I know cast iron is expensive but I reckon it's gotta be for a reason...)