-

Posts

52 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by PHDforge

-

I have a portable forge setup that I bought from Centaur with the sheet metal hood. The hood was rather thin sheet metal and rusted through pretty quickly and I patched it here and there. It only lasted a couple of years. Instead of buying another one, I decided to make my own with thicker sheet metal. This second hood I also painted both inside and outside with a heat resistant paint. I work outside under a pop up during the warmer months in NH. After breaking down my setup for winter, I inspected the hood and it doesn't have any rust that I can see yet (two years old now). I was surprised that the paint has held up too. I will probably give it another coat when I setup in the spring.

-

I bought the 5” Kanca vise a few years back when I first started getting into forging. It is a good rugged vise. The only complaint I have is that the jaws have deep serrations. I have to use sheet metal jaw covers to not mark the work. I’ve since picked up two other older vises. Funny that once you get your first one of something, others happen to become available.

-

I came up with an idea to mount various pipe sizes to a hardy shank I can change to different pipe sizes to form different radii with the adapters. What I didn’t include was a stop to hold the piece close to the pipe. if I had holes in the plate, I could mount an adjustable stop- like ones used on milling machines. I may grind out the welds holding the plate to the tube to be able to bring the plate back to the mill for extra holes someday.

-

I happened upon 12 x 12 x 1 inch plate and decided to make a stand for it. Have access to a milling machine and milled a 1” square hardy hole. I set the height lower than my anvil to make it easy to use with my guillotine tool. (Lowers hammering height) Only problem is that I wished a drilled some additional holes in the plate before welding it to the stand.

-

TW Got your Christmas card a few days ago. My wife and I liked the decorations on the image(don’t want to give away the theme). I take it that it was Max approved. I had never thought that I would actually like to get coal until taking up this blacksmithing hobby. Bob

-

TW- I haven’t been able to get back to the forge lately with other chores keeping me busy. Finishing my ghost (or bird) letter opener will have to wait for another day. Great work everyone! This was a fun challenge and many excellent ideas emerged. There is much talent in this group!

-

Good pieces for a demo

PHDforge replied to BayardStrachan's topic in Blacksmithing, General Discussion

Doing simple things with a twist. Kids seem to like seeing a twist. I do S-hooks with a twist in the middle. -

What did you do in the shop today?

PHDforge replied to Mark Ling's topic in Blacksmithing, General Discussion

Jennifer, that bolt header vise is an interesting piece. I can see the idea now. There is so much to learn about old tooling. -

What did you do in the shop today?

PHDforge replied to Mark Ling's topic in Blacksmithing, General Discussion

Jennifer, Excuse me for not knowing but what is a bolt header? Is it a similar tool like a rivet header? -

What did you do in the shop today?

PHDforge replied to Mark Ling's topic in Blacksmithing, General Discussion

Jennifer, that vertical holdfast is a fantastic idea. I see in your video that you do not take credit for the concept but you state that you have not seen another one. How did you come up with this idea? I have a background in design engineering and after watching the video, I tried to think of other ways to accomplish what this item can do. All other vertical clamping ideas I came up with would not let the work piece lie flat against the anvil. Great design! Bob -

What did you do in the shop today?

PHDforge replied to Mark Ling's topic in Blacksmithing, General Discussion

JLP: I did stop by your trailer, and watched you working. You make it look so easy. You showed me your vertical hold down hardy clamp tool. Watched your video on how to make it too. I may give it a try sometime. -

What did you do in the shop today?

PHDforge replied to Mark Ling's topic in Blacksmithing, General Discussion

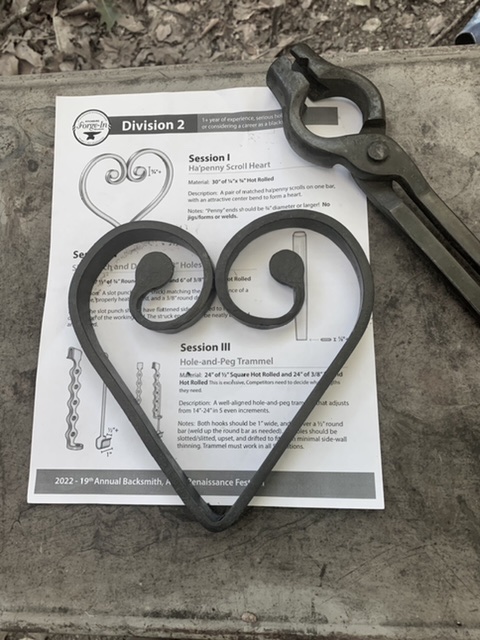

Nice work everyone. I like those pumpkins, cool idea. I went to the Fitchburg Forge-in last week. I didn’t compete because I knew I could not do the projects in the allotted time frame. So I tried one project today, it took me 5 hours (vs. the allowed 1 hr). Not perfect but I think it came out OK. Had fun anyway. Bob -

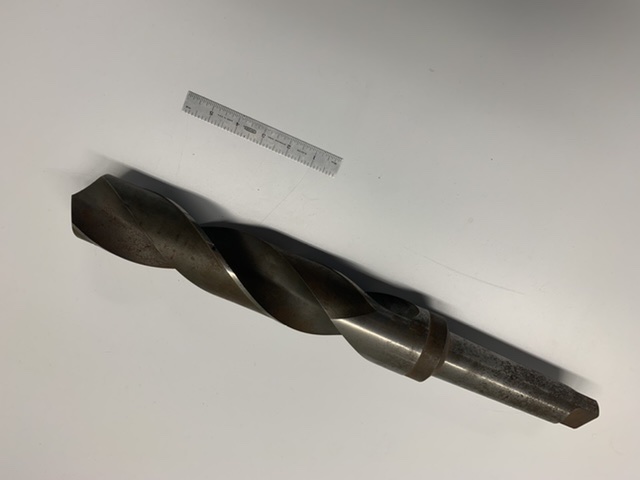

I believe it is a number 5 Morse taper. That would be a big machine to accommodate it. the cost was only a $1, so I had to get it.

-

You forgot to mention crossing the Bridge of Death over the Gorge of Eternal Peril and the questions three.

-

Scott, regarding gear cutters - IIRC each gear tooth size required a set of 8 to 10 cutters - each cutter had a range of the number of teeth which they could cut depending upon how many teeth were required on the gear you were cutting. Cutting gears also required an indexing head. You don't see many of these anymore either. CNC multi-axis machines have replaced much of the old way of machining. Our newest lathe at my college is part CNC and manual, but there is no compound rest, no thread chasing dial - single point threading can only be done in CNC program mode. Here is a drill I picked up awhile back. Can’t really use it. 2-9/16 in diameter. It’s still cool to have though, interesting conversation piece.

-

Nice work everyone, some interesting designs. Rojo, I like the design of the reversed blade. It does look like a harpoon. Cool looking!

-

I guess it does look like a bird in the photo. When I took the picture the ghost was vertical, when uploading it turned 90 deg, I wasn't able to find a quick way to rotate it. All the more reason to add an elbow bend to the arms. It is all about interpretation I guess. My round hole punching is getting much better, I can match the back and front. It the slot punches I have difficulty with, can't seem to get them to line up. More practice is the remedy. Thomas, I have another idea for a jack-o-lantern themed letter opener. Stay tuned.

-

Thanks. The eyes are not rivets. I first considered punching thru holes. I punched first from the front side and as I was punching from the back, I decided to leave the slug centered in the middle of the thickness. It looked cool and the eyes are still seen on both sides. The use of rivets as raised eyes is a great idea too. I started with a piece of 1/4in plate 2in x8in and my intention was for it be made from one piece.

-

Here’s a Halloween themed entry. Still needs finish work, also not quite decided final positioning of arms.

-

End mills are the cutters. Two main types of milling cutters- peripheral and face cutters. Face mills designed to cut surface perpendicular to axis of spindle, usually large diameter. Side cutters cut parallel to spindle axis. End mills are a combination cutter that can do both, but usually smaller than face mills.

-

Suggestions for an anvil stand dimensions

PHDforge replied to Kelly R's topic in Stands for Anvils, Swage Blocks, etc

A local steel supplier started putting out cut stock remnants or “drops” on racks outside his warehouse. All kinds of sized stock. I found some 2 1/2 square tubing that was perfect to receive 2 square. The legs are 3 1/2 square tube. Price for drops is by the lb and decreases as you buy more. I go steel shopping often. Only problem is inventory changes. -

Suggestions for an anvil stand dimensions

PHDforge replied to Kelly R's topic in Stands for Anvils, Swage Blocks, etc

I hate to admit it, but I paid $900 for it last year. It has been repaired, edges have been welded. I do not know for sure if it was done correctly. Rebound was great in all areas on the face. Edges are still rather square. I have yet to round them. Built the stand this year, so first year in use. I learned on another anvil, so I am more experienced now. So far it is holding up fine. I took a chance on it and the seller was up front about not knowing if the repair was done correctly. Time will tell. -

Suggestions for an anvil stand dimensions

PHDforge replied to Kelly R's topic in Stands for Anvils, Swage Blocks, etc

I also decided to make a tripod type stand for my latest 200lb PW anvil acquisition. Used an angle iron fabricated pan to contain anvil on top of a tubular assembly. The tubes can receive 2” square tubing attachments from any side. I have to give credit to Jennifer for the idea of including receivers. -

Another use for stringy lathe chips: while managing a machine shop at a college, I was approached by a person who did wood working. He asked for stringy steel chips, didn’t care if they had rust on them. In fact, he wanted some rust. I think he was using them to antique the wood IIRC. Like a very coarse steel wool. there are all kinds of uses for recycling, if you use your imagination. TP: interesting example that you saw. Maybe with the canister method the powder would fill the voids. The idea of using chips occurred to me while watching fish hooks being used on FIF.

-

Could machining chips be used for Damascus work? Cannister?Unfortunately I do not have the skill set (yet) to attempt something like it, but I wonder what patterns might emerge.