-

Posts

56 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Baton Rouge, Louisiana, USA

Recent Profile Visitors

457 profile views

-

Iron Kitten Forge started following Shainarue

-

Iron Kitten Forge started following ABANA Level I Zoom Classes

-

Do you have a picture of what you're describing, Frosty? Would it be like a open top gas forge?

-

I see Otto Engel in my material and supply list email too. I guess we'll find out this evening. We might be in the same class.

-

I don't see who my instructor is. Where does it show?

-

Who all is gonna be in the level 1 zoom class tonight? I've been looking forward to it.

-

Iron Kitten Forge changed their profile photo

-

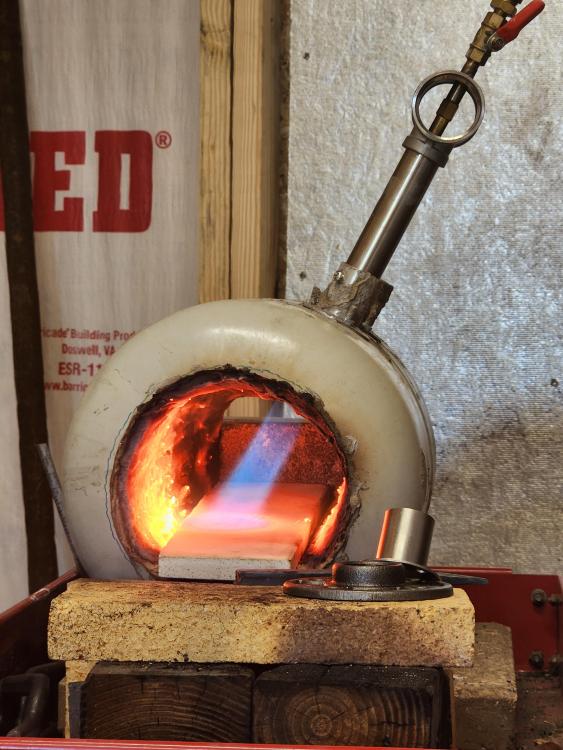

Forced air burner producing carbon monoxide

Iron Kitten Forge replied to Iron Kitten Forge's topic in Gas Forges

Update: i shortened the air hose to try to minimize flow resistance and it seems to be working much better -

Hello, i need some advice. I picked up a used home built forge. The issue came when i was lighting it the first time. A minute after i lit it both of my carbon monoxide detectors started going crazy so i immediately shut off the forge and went outside. I've been searching around for tips on tuning one of these forced air burners without much luck. My best guess is that I'm not getting enough air flow/pressure?

-

I picked one up, it's pretty sweet. I got the ductile iron version. Now i just need a forge big enough to heat larger sheet metal so i can make bigger bowls

-

by "moveable baffle walls" do you mean doors to close in the forge more or something inside the forge itself? i might have missed that thread

- 49 replies

-

- diamondback

- majestic

-

(and 1 more)

Tagged with:

-

Thanks! I've been reading for a few years now. I know it's not pretty but its getting way hotter way faster so I'm pretty happy with it so far

- 49 replies

-

- diamondback

- majestic

-

(and 1 more)

Tagged with:

-

- 49 replies

-

- diamondback

- majestic

-

(and 1 more)

Tagged with:

-

Thanks, that's good to know. I don't wanna get to class and realize i don't have the materials or tools for the class.

-

I signed up for the same class. I didn't see any kind of recommended materials list or prep work for the class. I'm not really sure what to expect in the class. Defiantly looking forward to it though!

-

Thank you for the advice, i got some kiln shelf from a local shop and I'll practice cutting it this weekend

- 49 replies

-

- diamondback

- majestic

-

(and 1 more)

Tagged with:

-

I haven't used kiln shelves before, are they easy to cut?

- 49 replies

-

- diamondback

- majestic

-

(and 1 more)

Tagged with:

-

I've thought about re lining and putting an extra layer of insulation but I'm thinking the resulting internal volume may be too small.

- 49 replies

-

- diamondback

- majestic

-

(and 1 more)

Tagged with: