-

Posts

63 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by WRLD

-

I've definitely seen the term thrown around very losely. I'm still working on breaking some of the bad terminology I've picked up. I'll get there

-

My apologies.. I completely misread your last post. I plan to harden 1084 in the forge and then temper it in an oven.

-

Noted. Thanks Frosty. I plan to use 1084 steel

-

I fired the forge on low for a couple minutes and then let it cool this morning. Now later in the evening I fired and ran it for a bit.

-

-

Funny enough, I made the press to make the sheath out of XPS foamboard, It works pretty decent. Thank you! Completely 100% agree. I've been practice grinding on 1/8 and 3/32 stock and I've liked it much more then the 3/16 that I was using. Thank you for the commemt

-

I can completely see what you are saying. I discussed ergonomics with my friend briefly after using it for a little bit and he hit on a few similar points. I appreciate the advice I'm sorry, I think I might have misspoke. I was getting inconsistent results attempting to heat treat 1095 steel I switched to 1084 steel and got much better results. From what I understand 1095 steel requires a specific tempature for a specific duration of time in a kiln/forge. I couldn't do this in my forge. When I switched to 1084 steel, I believe that I got better results because 1084 steel doesn't require as precise of a heat treat. I hope I'm not still butchering this. Thank you for the long and thought out comment. I I really want to grow in this hobby and I feel like this is a big part of it.

-

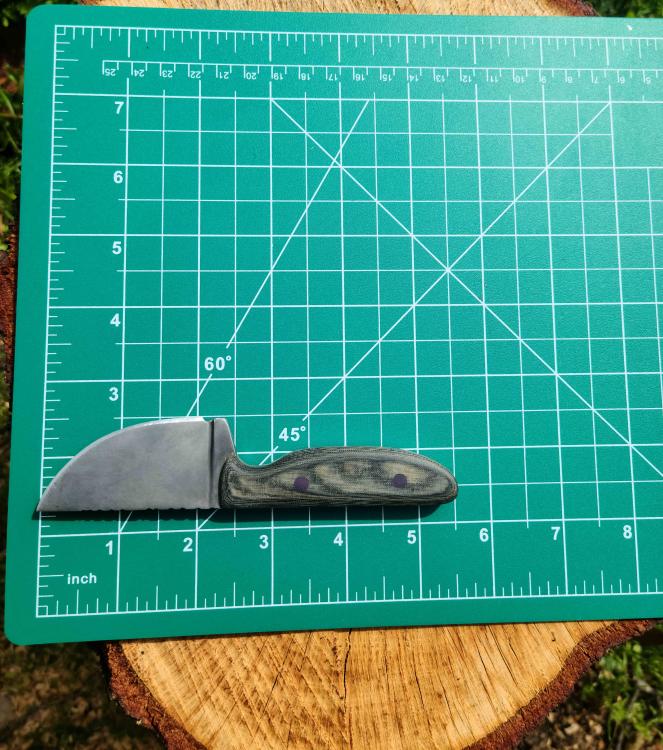

I made this for a friend's birthday. It's 1095 with micarta scales. I used my 2 brick forge to heat treat and tempered it with a toaster oven. I started using 1084 after this knife because I wasn't happy with the inconsistent grains I was getting while trying to soak 1095 in my little forge. Going forward I want to be more consistent with my bevels and overall fit and finish.

-

Thank you people! There seems to be a lot of knowledgeable people here that don't sugarcoat things. I think I'll get along

-

Last bit of kastolite is setting. My shop has been around 86°F today. I've kept a damp towel over the forge, Everything seems to be curing pretty nicely!

-

Will do! my bad. I'll admit I wrote that in a haste and should have proof read it.

-

Hello! I'm about 2 months into the world of knife making, which very quickly is turning into blacksmithing. I'm in my mid 20s. I grew up on a ranch, I'm currently building a bus to live and travel in with my lady. This hobby feels right so I'm going to just keep going with it

-

Just half of the burner port left to do! I went a little thicker on the floor/wall transition that the burner points at. It's definitely quite a bit heftier than when I started. Do you guys think I would be wasting my time setting up a thermocouple in this forge for heat treating? I was thinking about using square tubing to place knives in when I heat treat. Maybe I could just have the thermocoupler in the square tubing instead of in the forge itself? Just typing my thoughts

-

One more roll should about do it! I might do a couple patches on the floor where it's a little rough, *I didn't notice that yesterday. I'm pretty excited to run this thing but I'm trying to not rush and do it right.

-

Perfect sense. Thank you

-

I live within a couple hours of them, my grandfather worked closer to the area back in the day though so that sounds about right. Come to think of it, I have a couple railroad anvils that I believe he made as well. I'll take an accurate measurement to see. I'm thinking I'm going to bring it into the shop to use as an anvil for now, I've never checked to see if it's cut sqaure. I hadn't thought about that! That may be a thought in the future though. I've had fun falling Into this hobby so far

-

I only got a photo in the beginning, kind of lack luster but progress! I was able to get above the rear exit as well. I'm considering building a fire in the shop tonight because the shop will probably be in the low 40s again and I'm a little nervous that it could get colder. Looking now it appears I might have forgot to take my tape off before firing it earlier lol

-

That makes sense. Kastolite 30 is probably going to take me a couple days. I'm worried that my floor will give way if I flip it to coat the roof. Would It be better if let it dry enough to flip it then proceed with the high humidity cure? Or cure the floor then in a couple days do the roof?

-

Fired the rigidizer to dry it. Had a little bit of trouble getting the burner to stay lit. I think it was angle problems. Ran it at low for a bit then turned it up to get it red. Noticed the food coloring is gone? Also the blanket feels firmer but not rigid. Ahh, should I have left the blanket wet with rigidizer before the kastolite? I assumed Dry rigidizer & blanket then kastolite & letting it dry slowly

-

Well that works in my favor, I should be able to get the refactory started today then.

-

yeah? i might just walk back over to the shop to do that. the low for tonight is 40 and my shop doesn't have a fire going so i probably should.

-

its round, my grand father acquired it at some point in his life and it ended up here.

-

ahh, that's a relief. Hopefully it will dry by morning

-

I have this piece of steel on my property, I'm not sure where it came from but it rebounds kind of like an anvil. Any ideas what I could do with it?

-

Made some progress today. Little worried that I forgot to fire the forge before putting the 2nd layer of kaowool after rigidizing. Should I be? I remember reading that somewhere.