-

Posts

4 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Taitius

-

-

Well, as you know Njanvilman I recently got a 200# cast in 1965 (you answered some questions about it in another topic) and I have two others that I mentioned in this topic earlier. I finally have pictures of all three.

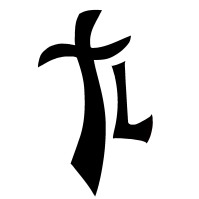

The small 60# has FISHER cast into the front of the base and a 6 on the front right foot.

The one with the logo has a patent date of 1877 cast into it, but has no weight cast on it (it is 140lbs), this is my current working anvil.

The one with the lugs is the 200# 1965, it will be my new shop anvil as soon as I fabricate a stand.

-

I just picked up this anvil at an auction for a good price. You may not be able to tell from the photos but it looks like it has barely been used, needless to say I was not willing to leave the auction without it...

It has no logo---------but I'm almost 100% sure it is a Fisher because of the shape, bolt lugs, and weight cast into the right front foot (200). It seems to have a heavily flaking layer of creamish colored paint over, what appears to be Navy Gray... I suppose the gray could be some sort of primer, but I suspect it may have been the original paint job and this was a navy anvil, I believe the Navy purchased Fishers exclusively. Given the lack of a logo I'm assuming it was perhaps cast in the 1950s or 60s? The only markings I've found so far is a "200" cast into the front right foot and an upside-down "R65" cast on the base below the heel, there is also what looks like a little tag mounted that says "14065".

Maybe you can weigh in on this Njanvilman, am I correct-----was this maybe a Navy Fisher from the aforementioned time period?

-

#140 lbs w/patent date of 1877 & a 60lbs w/no date that I can see.

52100 heat treat problems

in Heat Treating Knives, Blades etc

Posted

So I have a little problem and I am kind of stymied... I bought a bundle of various sized 52100 round stock a few years ago at a blacksmithing event, can't remember the details at the moment. I just recently pulled it out and tested a small piece for a slipjoint knife build. I forged the shape, ground it to near the final thickness, normalized and hardened. Low and behold I barely get 50 HRC... Did it a second time and got virtually the same result---------so I see 3 possibilities: I got sold something that isn't 52100, my heat treat process was totally wrong, or I had massive decarb.

I don't think decarb is really the issue because I ground away the surface steel and put a wash of satanite on before the hardening (the second round was done without the satanite just in case that had botched the quench, but results were the same).

My heat treatment may have been a bit off, but I still wouldn't expect to get such low hardness. Here is the procedure I used:

2 normalizing cycles at about 1475, held for about 2-3 minutes then air cooled. Bring up to 1500 then hold for 10-15 minutes and quench in 125 degree cooking oil--------as quenched hardness was only 50 HRC. My temperature control should be pretty good, I use a thermocouple in my forge to monitor temp during heat treats. I also used a similar process to harden some W1 (with shorter soaking times) at the same time and I got a hardness of 65 HRC.

So, any ideas what might be going wrong???