-

Posts

14 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Holger

-

I will use it flat the most. I am thinking I’ll lever it up on a steel ramp from my trailer that I will tack or somehow secure to the stand temporarily. I can flip it with a 4’ steel rod. Whatever I build, it needs to be stable as I don’t like the idea of it tipping over while levering the swage onto its edge. My workspace is outdoors so I don’t have a truss to hoist from or a smooth floor for an engine hoist. I could use a tripod or possibly rent something.

-

Just gently tossed this little bad boy in the back of my truck and skipped home. Marked 4 1/2 on the top face. I think that means its around 230 to 250 Lbs or so. I am considering how I am going to build a stand for this and some of the older posts are unavailable. I'd love to hear what has worked for all of you. I have reviewed all of the posts back to 2016 or so where photos are no longer hosted. My Metal fabrication skills are just ok, so any advanced designs are impractical for me, but I do have an oxy acetylene cutting torch and an underpowered AC stick welder, cutoff saw etc. I am an OK welder as well. I have access to some new PT railroad ties which could work for this, but I have to pick them up and if they stink, I'll be passing on that. Having never used this Block, I'm mostly concerned with how high I mount it, and due to its weight I do not want it falling over. Thanks for the input.

-

I haven’t been to Moapa since high school. It’s always nice to be outside in SoNev during the winter ( when it’s not windy).

-

I actually think the formula is for a London pattern. I didn't see one for American anvils, and as I recall someone else applied that formula to an Arm and Hammer and came up with an over weight estimate too. I thought I would post it as an additional data point.

-

I'm going to include the dimensions of my newly acquired Trenton since I found this kind of stuff useful when I was researching it. Length of Face = 19.75", Width of Face and table = 4.625", Length Table = 2.5", Step height = 1", Hardie = 1", Pritchel = .75" Dia, Horn = 9.5" from step to end of bick. Overall length = 31.75, Height = 12.25", Length of base = 13.5", Width of base = 11" And apparently I'm really bad at estimating weight. I thought it was 150 pounds and it turns out that it is actually 225. I thought it felt just a little heavy when I picked it up to get it in and out of the truck. If I apply the formula that I have seen out on the internet (LxH)-110=weight, I get 278Lbs, for whatever that is worth. Other than the faint Trenton logo, I cant find any other markings at all.

-

I use sacrificial steel when punching and cutting with a hot or cold chisel. The ears will keep it on there when I'm doing that, and it comes right off. Whoever used this anvil before wore a pretty decent groove in there.

-

First I need to get the chainsaw and cut a stump for a temporary home, like right now. I'm itching to get hammering.

-

Just the wire wheel to get the rust off. It won't need any modifications except maybe a sacrificial piece of mild steel with ears on it to put over the table to keep from putting more dents in that. I promise I won't weld it on.

-

Well, I bought it for a good price. I cleaned it up and have some better pics. Looks to me like it might it might be a trenton. weighs around 150 pounds, I'll weigh when I get it home. I passed on a swage block as it didn't have any dished surfaces in the center just really large square holes.

-

I’ve been working with metal for a long time now, but am finally focusing all my spare time in this hobby. Worked a brief stint at an ornamental iron shop in the 90’s where I got the opportunity to play with really big hammers, and some smaller ones. It’s so much fun to make your own tools and solve problems.

-

I didn’t see any, but I’ll look for them. How did Trenton typically mark their anvils?

-

Thanks for the reply. I’ll try the chalk trick. I thought it might be an arm and hammer as it has a concave oval on the bottom.

-

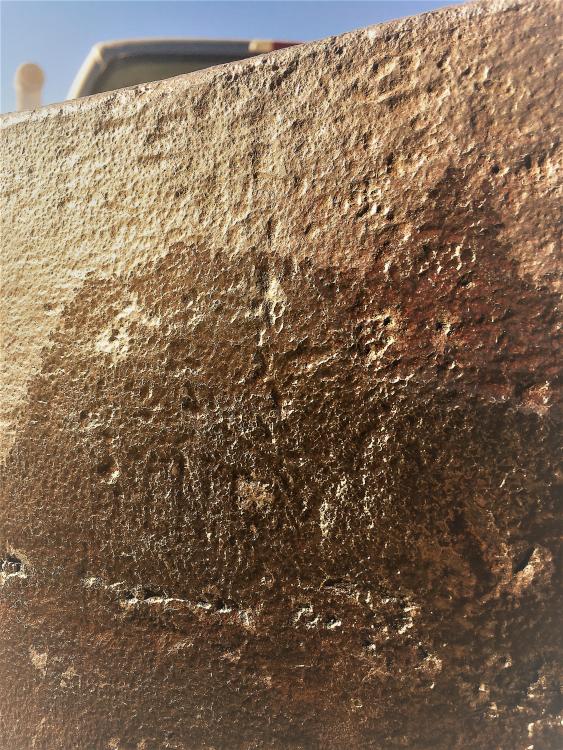

Well, I tried the TPAAAT method and had results within 24 hours. Now comes the part where I try and figure out how much to offer and get some help from you folks on what kind of condition this animal is in. I will go back tomorrow with a ruler and a ball bearing and test the rebound, as well as lightly tapping all over the face horn and heel. I did tap the face once and it rang very strongly, sort of like a bell. It seemed very hard. I think it’s cast steel, It weighs around 150 pounds and the only mark I could find on it was sort of indistinct under the heel. I’ve included a photo. At the bottom of the anvil there is an oval shaped indentation and everything else seems like it’s intact just a little bit of wear on the step and face. I also found a swage that looks to be at least 100 pounds and numerous tongs.