-

Posts

521 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Jobtiel1

-

Yeah I don't think it's a saw set anymore, a wire stripper is possible and seems more likely. Nevertheless it's a very cool tool! ~Jobtiel

-

Gewoon ik, Thanks a lot!! ~Jobtiel

-

Great! Do you by any chance have an idea about the size of the jaws and the spacing of the guide rails to the screws, Also is the back jaw flush with the workbench or offset? Thanks! ~Jobtiel

-

The second tool is possibly a saw set, but I haven't seen one that look like that yet. The depth stop would indeed be for easily setting the saw teeth equally. ~Jobtiel

-

Welkom op het forum Ferdinand, hoop dat je er veel leert en vooral plezier hebt! Welcome to the Forum Ferdinand, hope you learn a lot and above all have fun! What a hammer, If I had it I'd make a treadle hammer with it. I picked up a roughly 13-15 kg sledge at a flea market that I'm going to use with a treadle hammer. As for striking with it, that might be a little much. ~Jobtiel

-

I'm making a wooden woodworking vise for the woodworking bench, the other screw I save for an eventual tail vise. I have some ideas to forge a few parts I still need, I'll have to try them out next time I light the forge. I think it will be a vise with two steel guide rails and a centered screw instead of a vise with one guide rail and an offset screw. ~Jobtiel

-

Went thrift shopping this weekend, and I found a pair of vise screws for woodworking vises. I bought a scaffolding jack and started making my own one, but that project can be postponed now! Best part, the thrift shop asked 2.50 each. ~Jobtiel

-

George, I understand, I have to see how I like it, maybe I'll rivet through the wood using some nails. Anvil, I have some pics but not from before I put it together, I followed the video from DF in the shop for a simple chest lock. Basically it's a bolt that is moved by the key through an indentation on the bottom. There is a ring fixed to the backplate where the key falls in. There is a spring that gives tension to a bend strip that lock in two divots on the top of the bolt, this gives it it's two positions to open and close the lock. There is no additional security so anything that can slide the bolt can open the lock. The spring is from an old recipro sawblade. You still see the lettering. ~Jobtiel

-

Little update, I finally finished the chest lock! As you can see it's been in use. I know screws are not the most secure way of attaching a lock, but the lock itself can be opened with a bend nail, so it's there more for the looks. ~Jobtiel

-

Nice deal! they show up here on a regular basis as well, quite cheaply at around 100 euros for a simple model, yours looks like a proper beast! As soon as I get some more space one of these will be high up the list. ~Jobtiel

-

Never thought of it that way, when I saw them in use, I always thought the ends would be square pointed like a nail. Once I make some I have to remember this. ~Jobtiel

-

On axes I use home-made paste wax after use. On hammers I don't mind a little bit of rust. I've found that yearly BLO (or less because I forget) keeps the rust away. Even next to the sea where the wind is always coming from. On (top) tools I don't do anything at all. ~Jobtiel

-

What did you do in the shop today?

Jobtiel1 replied to Mark Ling's topic in Blacksmithing, General Discussion

Bayard, at those thicknesses steel can get hard without quenching as it's still cooling fast, you need to let it cool slowly to anneal it. Jigsaw blades have holes in them already, maybe that's an option for the spring? Sometimes when forging spring steel it contact quenches on the anvil and shatters while working. same problem really. ~Jobtiel -

Me too. and even if you use charcoal as is it works fine for filtering without even activating it. It is a good color remover and together with other stuff to remove particles you would only need to boil the water to get good drinkable stuff. With activated you might need less but if you grind the charcoal down to a powder it works well enough. In chemistry to separate compounds one of the most used compounds is also carbon. A chain of 18 carbon atoms with hydrogen attached bonded to a silica backbone is one of the most used separation devices for organic chemicals. ~Jobtiel

-

So plugs in America are 110V normally and your high power plugs are 220? is your amperage higher then? We have 220V normally and our high power outlets are 380 V.

-

That's prime summer temperatures! We are currently at the 14 degC (57 F) already. While it will clear up a bit next week, autumn really has started. ~Jobtiel

-

Older ones feel so much better. I got an oldish stainless steel one I keep in my apron. Both metric and imperial, which is convenient. Fun thing we call this a "duimstok" or thumbstick, but one "duim" is roughly equal to an inch when talking about it as a measuring unit. Pipes are often still sold with this measuring unit as the standard, i.e. 3 duims pipe is around 76.3 mm I.D..

-

Good stuff, that should help you out when it's summer again. Or do you still have those insane temperatures over there. I can confidently say that summer in the Netherlands is over. It was a fun two months. ~Jobtiel

-

pea coal or nut coal

Jobtiel1 replied to Bud in PA's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

I have seen people have a coal storage that is out in the open. I've heard of water infiltrating in the coal seams and when it freezes it breaks up the coal. Are there more downsides to storing coal in the weather? ~Jobtiel -

I have done a test piece already and need to make a new punch first, But I'm working on it! ~Jobtiel

-

I always like seeing your reminders Glenn, thank you, and I should start soon on making the gifts I was planning for last year. I was thinking of making a bottle opener or corkscrew for everyone depending on what they like to drink. But I'll have to try making a corkscrew again, the last one failed miserably. ~Jobtiel

-

What did you do in the shop today?

Jobtiel1 replied to Mark Ling's topic in Blacksmithing, General Discussion

Some soft woods are also harder than some hardwoods, which can make it even more difficult. ~Jobtiel -

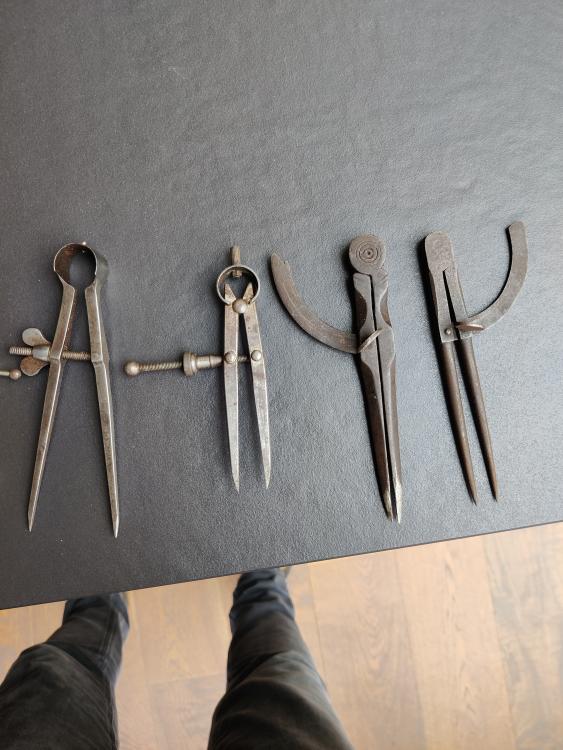

Another mail call today on a couple of old dividers and calipers. Some larger to use during forging, some smaller for layout of smaller stuff, and some nice round pointed for woodworking. Very happy on the deal! Paid 40 euros shipped for the lot! ~Jobtiel

-

Welding base of anvil

Jobtiel1 replied to Robert campbell's topic in Repairing and Modification to Anvils

I had no sliding issues with using straps to hold the anvil, I have also put silicone caulk between the stand and the anvil, which dampens, and would also help resist sliding motions. alternatively you could use wood shims as there is less chance of sliding happening between wood and iron. ~Jobtiel -

Welding base of anvil

Jobtiel1 replied to Robert campbell's topic in Repairing and Modification to Anvils

First of all, welcome to the forum, if you put your general location on your profile you could meet nearby smiths who can help you as well. If you put some metal on your stand to make the face level, you don't need to weld anything to the anvil. I have done the same by drilling a hole in a piece of bar stock, cut a square, and screwing it to a wooden anvil stand. works perfectly and you don't need to go to The expense and troubles of welding on the anvil. ~Jobtiel