-

Posts

3,598 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by John B

-

What did you do in the shop today?

John B replied to Mark Ling's topic in Blacksmithing, General Discussion

About 25mm/1" diameter works OK, or you can slit at 30mm /1.25" and open up to the required diameter on the bick -

What did you do in the shop today?

John B replied to Mark Ling's topic in Blacksmithing, General Discussion

Drifts are bettertapered at both ends, and the finish size/shape of your required hole on the central portion so they can be knocked through and finish size the hole being made. Use the one you made as a drift, and it will be producing an Hexagonal shape hole If you need some practical advice you are welcome to come along to one of our BMASW members days at Westpoint Forge, Exeter, second Saturday in the month, and we can chat and show you what we use, and discuss various options. -

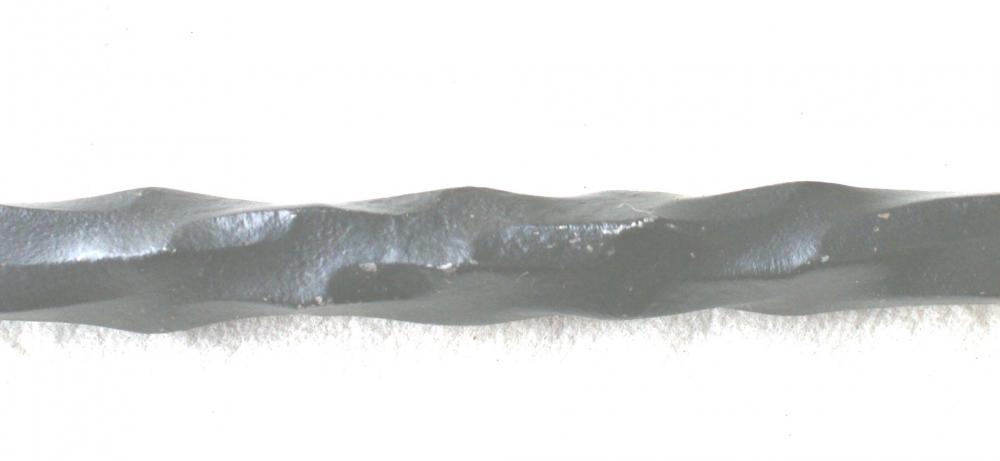

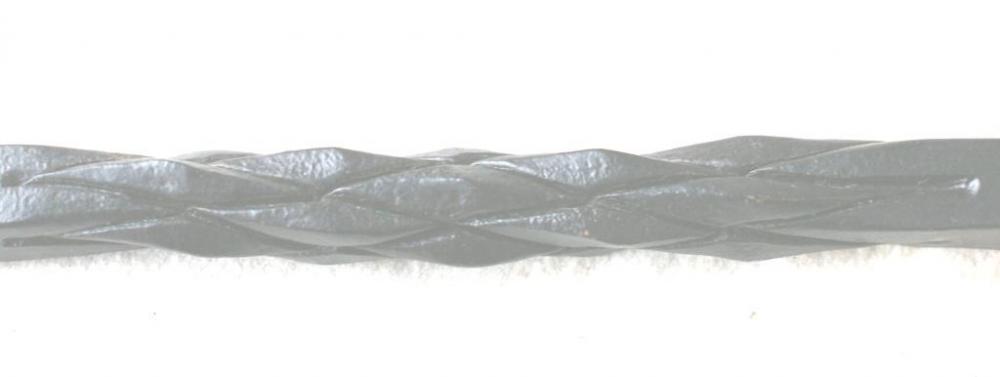

Hi Sascha, Preparation for both is the same, Incise two opposite sides near to the edge, the length of the twist section required, then make a short ¼ twist, then make a reverse ¼ twist at the desired spacing, and repeat along the required length Both twists are basically the same, one has a quarter of a turn, as long as you wish, The second twist is the same proceedure, but a half a turn twist is used, I believe these were known as Water twists The quarter twist has the incised line showing at the edges in an intermittent pattern, the half twist results in the incised line visibly running in each section , it does not show in the picture, as it was taken from the no show side You could do the same twists but without the incising. Enjoy !

-

What did you do in the shop today?

John B replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Show me your Bottle Openers!

John B replied to Arbalist's topic in Blacksmithing, General Discussion

The point of the question was to try to make is that as blacksmiths, we should not assume, but get our facts together and act on them. Many times I see items (usually made by people new to the craft) that do not seem to suitable for function, either comfort wise or safety wise. This is not a criticism, merely a comment, and some may note and act on it, others ignore it. If you are making it for your own enjoyment, then it's not a problem, however if you are making it to market, then safety and comfort become more important. Enjoy your Thanksgiving day -

Show me your Bottle Openers!

John B replied to Arbalist's topic in Blacksmithing, General Discussion

Well executed, but is this an appropriate twist for an item which has to be hand held? -

These are some of the ones in solid 1/2" square bar, I'll see if I can find the old samples and photo them again. I also have a selection of multi strand twists we have done on courses and elsewhere.

-

This is a Chess set and table that was made by James Deane and entered into various shows in the UK in 2016

-

What did you do in the shop today?

John B replied to Mark Ling's topic in Blacksmithing, General Discussion

Meteoric iron is like Wrought iron in the fact you have to try it to establish the best way of forging it, and it will depend on from whence it came. Some give up because they do not have the relevant forging experience to reach a successful outcome. When using wrought iron on a job, each bar was usually tried and tested before putting it to an application. Genaralisation is very misleading, Its like saying doing it the proper way, There is no proper way, so long as it works for you, and done safely, then I can go along with that, some ways may be easier or quicker than others, but that is usually developed as you go along the learning curve, and that is why you can learn faster being with someone in a hands on tutoring situation than trying to learn from scratch. -

What did you do in the shop today?

John B replied to Mark Ling's topic in Blacksmithing, General Discussion

The better your hand hammer techniques are will be of great benefit when you come to use a powerhammer. Many go the powerham before understanding how the metal reacts under a hammer. -

What did you do in the shop today?

John B replied to Mark Ling's topic in Blacksmithing, General Discussion

Youv'e got me ! (But teaching is easy money after the hands on making a living from smithing/apprenticeship) -

What did you do in the shop today?

John B replied to Mark Ling's topic in Blacksmithing, General Discussion

Depends on where you are going to use them,both are goodlooking, One to hang, and one to lay down, got to consider more than just comfort. (although the guys liking the cube twist handles' opinion may differ) -

looking for some tips on making a sauce pan

John B replied to ADHD-forge's topic in Blacksmithing, General Discussion

Thickness of the material will have a bearing on what techniques to use, and a fair amount of annealing may be required, or do it hot. Similar method to your your skillet, just has higher sides. -

What did you do in the shop today?

John B replied to Mark Ling's topic in Blacksmithing, General Discussion

BBQ forks, one with added bottle opener as a modification. Would be better if transition corner was left with more metal, instead of the step. Next ones will be better, lesson learned. -

Is this pipe galvanized?

John B replied to The Norwegian's topic in Blacksmithing, General Discussion

That appears to be standard steel pipe, if it was treated with zinc, or any other plating, the weld heat bands on the seam would not be visible, -

Cutting costs of cut costs

John B replied to WoodFireMetal's topic in Blacksmithing, General Discussion

In my family car, I carry large bolt cutters for exactly that purpose, can shear up to 1/2" square to suitable lengths to fit inside. Previously when i had a more industrial vehicle I had a guillotine/shear which would cut up to 2" x 1/2", mounted on a steel plate that extended from the rear of the guillotine/shear by about 12". I then used to park a rear wheel on the plate, and cut the steel as required, No Batteries, electric supply or a lot of physical effort needed, saving energy, especially mine! -

Tapering handle end of steak flipper

John B replied to Forgingforfun's topic in Blacksmithing, General Discussion

Always remember the shape of the section on the faces you produce is the same as the anvil face in relation to your hammers face, any slight angle from parallel will be reproduced, and that has a bearing on the next section that is formed from your next hit. -

An equivalent style of brush here in the Uk is what butchers use to clean off their wooden meat cutting tables,or you could try a farriers supplier if you have any over there.

-

That particular pen is paper correction fluid, in the UK it can be purchased as Tippex or Snopake Similar in operation to a ball point pen, Shake to agitate a ball internally to mix the fluid, then apply to the metal, depress the tip and squeeze gently to control the flow. Do NOT apply to hot metal, or ball will get stuck as liquid hardens, resists heat up to a reasonably high red. I am told the contents are a titatanium oxide, hence the heat resistance.

-

Solar Panel !

-

-

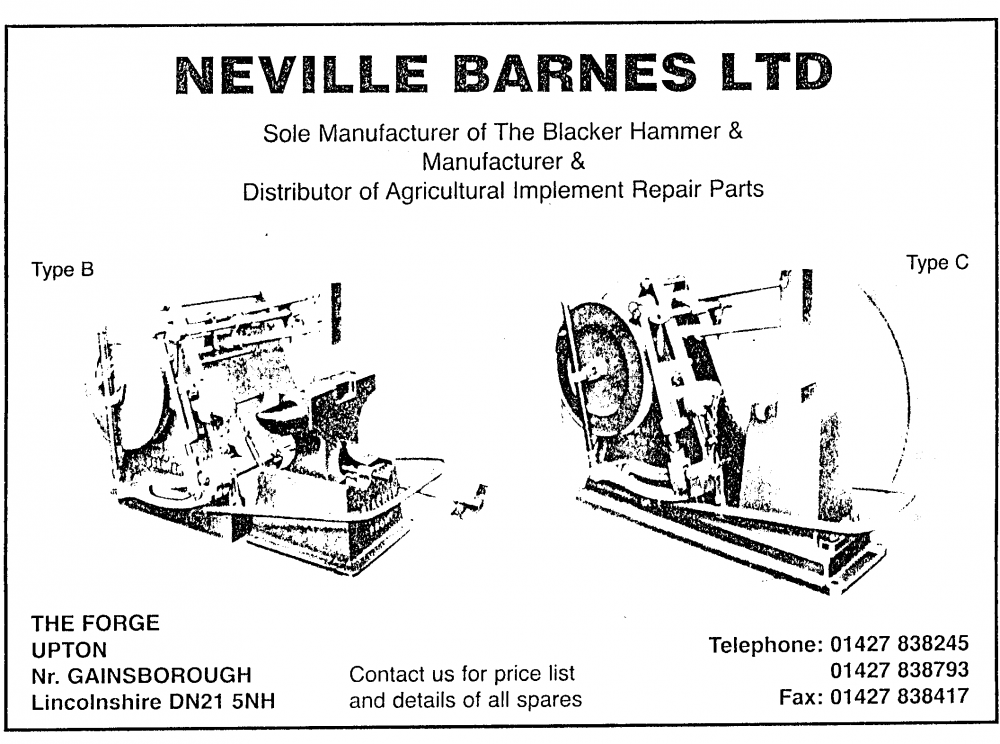

Blacker B info wanted

John B replied to Bearforge's topic in Power Hammers, Treadle Hammers, Olivers

Try a search on this site, or google, there are videos readily available. I also have manuals for the B, and C if you want to contact me. I have a C you can see working, basically the same as a B but without the traverse mechanism and large anvil. Whereabouts are you? -

What did you do in the shop today?

John B replied to Mark Ling's topic in Blacksmithing, General Discussion

I don't like gloves, so I use a leather palm protector Cut off (fillet) the wrist protector portion and put a slit in it for your hand to pass through. Left or Right Hand -

What did you do in the shop today?

John B replied to Mark Ling's topic in Blacksmithing, General Discussion

Don't know about that, all I can do is show them, and then it's up to themself, maybe beginners luck has something to do with it, or just a natural talent, in his favour he did listen, and had the desire. I think he may have got the start of "the addiction" -

What did you do in the shop today?

John B replied to Mark Ling's topic in Blacksmithing, General Discussion

Had a young man visit on our members day, and after he was watching what was going off, we let him have a play, Shown him what to do, and this is what he made, Pretty good I think for a first attempt.