-

Posts

28 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Menasha, WI

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

My understanding is that there's a point in the bell where you start creating a vortex that pulls oxygen down the tube with the propane. If you're too far back the vortex keeps the Propane from going adequately down the tube and as you move forward it gets richer until you get far enough in that the vortex itself has to taper, making it less rich, but the further down the pipe you move the less time the propane has to dispurse and mix with the oxygen, making your flame anemic. So there's like an effectiveness bell curve. You combine your nozzle depth with a baffle to create optimal mix and dispersal for a flame. Of course I could be completely wrong. I'm very good at being wrong. Just ask my wife.

-

That looks like it's a better version of what I was planning. I will probably steal the design.

-

I'm trying to take things slowly. I have been the "run to the forums and beg for help every time something little goes wrong" guy before, and it not only annoys the heck out of everyone but I don't get the chance to learn. So everything here is taking a lot longer because I spend about a week reading for every little thing that I need to fix, but I really am learning a lot. I'm pretty sure the yellow flame is just because I have too rich a mix. Gotta fiddle with sticking my nozzle a little further down the intake, think. My plan was to put rails front and back to slide fire brick into, but I wanted the bigger holes so I can put longer pieces of metal through. Right now I'm just firing the kast o lite after a couple days of it drying in the air.

-

VID_86630821_010055_409.mp4 Woo! I have an actual burning forge! My flame is way too yellow, so I obviously need to figure that out yet, and I need to get some shelf-type things welded on to hold firebrick to keep the heat in, but... I'm just so excited to have made all of these things come together!

-

Do you guys think one of those grout/cement-mixing drill paddles would work?

-

I'm not sure if I'm not mixing it right or what, but the kast o lite seems to either be really thick and clumpy or really watery and still somehow clumpy, and it transitions from one to the other in about the space of an ounce of water. It's driving me a little bananas. I've watched a ton of videos on how to use it and literally forbade myself from asking in the forums until I had read everything there was to find but I have no clue what I did.

-

-

I managed to get a usable fire going by lighting some lump charcoal and then feeding in anthracite. It was exhilarating to actually have a forge going. I put some hits into a piece of rebar. I suspect I didn't have enough coal going to put a good heat on it, but I managed to get it to a bright orange a few times, pound it into a point, lengthen an inch into two inches of bar, and then flatten it into a sort of spade poker tip. I've got to get better at heating this thing, and then I might be able to start some real practice.

-

I had no heard of them. Tha KS for pointing this out. Can you tell me about how much you pay for a 50 lb bag? I see I can get a 50 lb bag shipped from them for $60 and it may be cheaper shipped than a 4 hour round trip drive when I factor in gas and such.

-

Hello new friends, from the Paper Valley, WI

SharkBait replied to SharkBait's topic in Introduce Yourself

Awesome. A huge part of my thesis hinged on the foundational nature of Greek literature and the archetypal genres of storytelling. Creative Writing has served me well thus far. Being able to translate from High Legalese into the common parlance is a skill that has given me quite the leg up. Also, being able to make stuff up on the fly is a vital skill for anyone in insurance.- 12 replies

-

- newbie

- first post

-

(and 1 more)

Tagged with:

-

Hey guys, I don't really have many tools. I grew up around them and usually know what I'm doing with them but for a big chunk of my 20s thy just weren't a priority and when we bought a house a few years ago I realize I basically had none. So I've been slowly building up a collection. My birthday was Saturday and Dad got me a $75 Harbor Freight gift card. The next 3 big things on my wish list are a belt sander/disc sander combo, a drill press, and a welder. The drill press appeals to me because I do not have a steady hand and I have had a number of projects become way harder than expected because I can't for the life of me drill a straight hole. I do own a few drills, including a hammer drill, so while this does appeal to me, I am not sure how much it will improve my ability to learn and progress. But Harbor Freight's $75 8 inch does have very good reviews for what it is. I do really want a belt sander. I've done a number of projects where relying on the angle grinder and the orbital sander made them tedious and sloppy. I don't know how great Harbor freight's little $75 machine is. I can afford to supplement a little and with the sale they have going on I could realistically get the welder but I have no other equipment, no idea what I'm dong aside from what information the internet has to provide, and it is their cheapest welder. But it seems like an awful lot of getting into blacksmithing without breaking the bank relies pretty heavily on being able to stick metal together reliably. And every review I've looked at does seem to think that it's a decent machine for the price. If you were just getting started and had a choice between the 3, which would you go with?

-

Shopvac exhaust taped into the pipe. I have not figured out if we have a local ABANA affiliate or how I might contact them. I do think I found a fun event nearby around Halloween but that's about as close as I came. I was trying to get the coal going in the pan before I dumped it in the pit, rather than trying to build a teepee in a hole. Is that bad? I can stop if it's bad.

-

A gigantic post drill, but what model?

SharkBait replied to SmithingWitch's topic in Drills, Post drills, Mag drills, etc

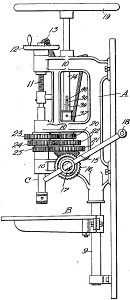

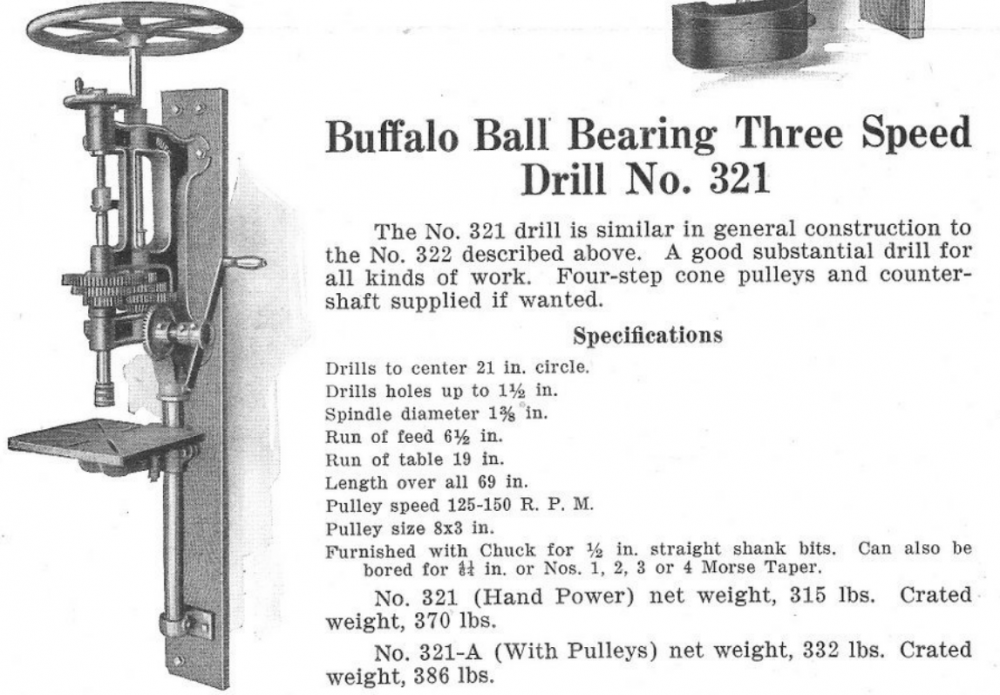

The 90 series and the 320 series were both hugely popular war-era machines and almost certainly saw a ton of what my grampa called "kerjiggering." The thing that makes me nearly sure it's a 320 series is the guide rail on the feed screw, which appears in the patent for the gearing system for the 320 and does not feature in any previous patent. The difference on the gearing is the missing middle step on the stepper gear and I can see a specialized factory pulling the 3 speed gearing if they didn't need or want people swapping gears because they felt like it. -

A gigantic post drill, but what model?

SharkBait replied to SmithingWitch's topic in Drills, Post drills, Mag drills, etc

-

Is charcoal an option? I wasn't sure if it was. Coal of the non-charcoal variety isn't readily available around here except for the few months in the fall when Tractor Supply has nut coal to throw into your haunted house bonfires for that spooky old world smell. At least I assume that's what its for because why else would you only sell it from August through October?