Hines

Members-

Posts

12 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Snohomish, WA

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Thanks for the tip. I definitely asked around for my stuff before searching online if that’s what you mean. Right now with the stupid rona virus it isn’t as easy. All of the big flea markets that usually happen in Washington didn’t happen. The northwest blacksmith association is doing virtual meetings only and their Facebook page is loaded with people asking the same questions about where to find an anvil or a post vise. Most people I asked if they knew anyone with a leg vise thought I was looking for used S** toys lol. When I was looking for an anvil, I found numerous old farmers that had big collections of old tools and when I asked if they knew anyone with an anvil they all pretty much said no but that would be pretty cool to have wouldn’t it. There was 2 people that led me in the direction of someone I wouldn’t have otherwise known they had an anvil and both times it wasn’t for sale even though they don’t do any smithing. The leg vise was a little harder for people to know what I was talking about compared to an anvil. But that was pretty much as good as I can do during this corona virus situation. Right now people In Washington are selling 70lb NC anvils with a homemade stand for $500+ and they don’t last a day at that price even though the anvil originally costs about $300 and can even be shipped for $30 from one website. I’ve seen at least 3 different NC anvils sold for that price in the last month and they sold quick. When I got my NC anvil on a stand that was supposedly only forged on twice I was lucky to get it for $200. I messaged the people within 10 minutes of it going up for sale and they still had to check their messages to see who messaged first so they can give me first dibs and hold it for me. I’m like “what are you talking about”? It just got posted for sale 10 minutes ago under an ad that said “garage sale” with no picture. I got pretty lucky and they also threw in a 100lb propane tank that’s still certified for 5 years and it was full, 3 nice heavy/sturdy tongs, 4 hardy tools, about 15 ft or more of 1.5”x.125” 1095 and 1075 steel, about 8 ft of big wide bandsaw blades he said was 15n20, all for an extra $40 on top of the $200 for the anvil. These people and their story of why they were selling everything they own in their house because they were “moving” still makes me wonder if it was even their home or their things they were selling. I’m a recovering addict and I’m telling you they were a little sketchy. But their phone was blowing up while I was there about the blacksmithing tools and nobody was interested in any of their carpentry tools or tons of antiques they had or the furniture haha. I’m just glad I didn’t end up buying my vise off of ebay and spend $300+ for a 4” vise that I don’t get to lay my hands on before buying. Anyways, I have a couple questions. The washer between the box and the leg on a leg vise was never made out of brass right? I’m pretty sure the one on my vise isn’t original but it works and I don’t see it failing anytime soon. Also is it common for the threads to be less pronounced and almost smooth closer to the handle where the screw kind of rides in the pocket of the leg in front of the handle? I can’t tell if they were machined that way or worn that way. The part of the screw that threads into the nut or “box” looks like it has plenty of strength and life left in it to do its job for a long time if I’m not putting a cheater bar on it. But the part outside of that, closest to the handle is worn enough it doesn’t seem possible to wear that much just from laying against the steel in the pocket of the leg when it’s turned. I guess anything is possible after somewhere around 100 years of use. My third question is if the legs of these things were forge welded together and if it’s common to see the seam of where the forge weld happened? I’ve never noticed it from pictures but you can’t tell in my pictures either unless I’m trying to show you. I also thought maybe someone shortened the leg because it didn’t have the flange at the bottom. But I can’t see any sign of it being broken or cut besides up higher where it looks like a forge weld. I measured the vise and its 42” or 43” long. Based on my research, that’s about the average height of these things no matter if it’s a 4” or 7”. I will post pictures of these concerns when I get the chance. I’m just curious. No matter what I’m still happy with what I got for the money compared to buying a cast iron vise from somewhere like Home Depot like most people I know. Heres another novel haha hopefully at least you can’t say I didn’t give you enough info.

-

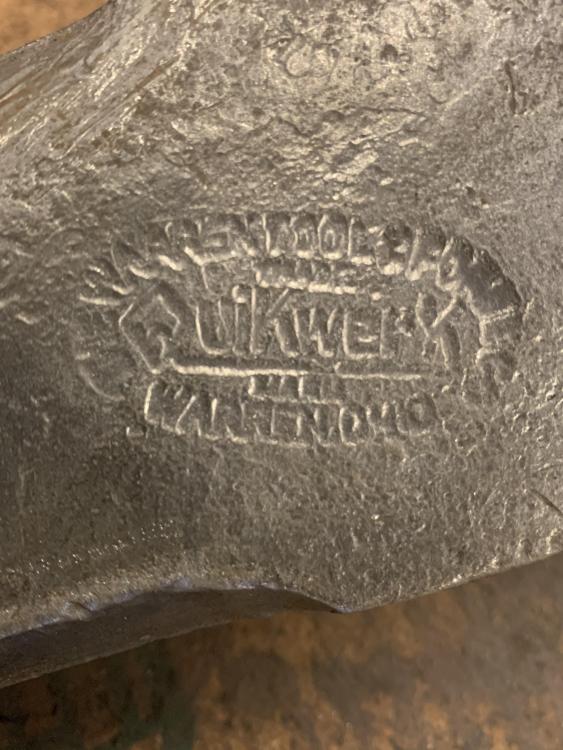

So I’ve been on the hunt for a decent post vise for a while now. Just like anvils in my area anything with a fair price is sold within minutes to an hour tops of being posted for sale. Every time I found one under $150 that wasn’t missing the spring and mount I was too slow to buy it. Finally someone advertised an estate sale mentioning they had a welding table with a leg vise on it for $250. They didn’t have any pictures and I managed to respond within 20 minutes of it being posted and I asked if they would sell the vise separate from the table (although if I had a way to load the table I would have bought the combo because the plate of steel alone on this table was worth the $250). The lady selling it was probably at least 70 to 80 years old and said she wasn’t tech savvy enough to send me pictures but she told me nothing is missing and it works and she would sell the vise separate for $150. I had a good feeling about it so I made the 1hr and 20min drive without seeing pictures. My budget for this vise hunt was $150 to begin with and I was going to be happy with a 4” vise. When I got there I realized it wasn’t the original mount and the spring didn’t look original but the spring seemed to work good. I tried to offer her $120 just because it’s always worth negotiating someone’s asking price with something you find on Craigslist. I said “will you take $120” and I started to try to tell her why I’m offering less saying “it’s not the original spring, it’s not the original mount, and one of the washers doesn’t look original”, but before I could even finish the old bird just said “no, no, no” and she turned around and walked away to go help someone else who might want to buy some of her other things. She wouldn’t even talk to me for less than $150 so I paid it. I didn’t have a tape measure with me when I bought it and I thought it might be a 6” but when I got it home and measured it I realized it’s a 7” and I found a stamp on it that says 140 so I’m guessing that it weighs #140. I don’t know what the going price currently is on a 7” post vise but the jaws line up, the threads look good, the spring works great, and it’s almost twice the size of what I thought I was going to get with my budget so I’m happy. It was stored outside so I took it apart and cleaned up the rust. I plan to forge a new mount one of these days and possibly reuse the spring that someone already made for it if I can cut the weld and save it. I think the original style mounts look cool compared to what’s on it now but the big plate that’s on it works. Someone had welded the mount and spring to the vise but I think I can cut the welds with a grinder and clean it up when I decide I want to make a new mount. Sorry for writing a novel to tell you guys the whole story. But after missing out on multiple sales that were only advertised for 30 minutes I was excited to get this one. Here’s a couple pictures of the vise and my cleaning of it. It’s not perfect but I don’t think it’s bad either. Oh and it’s stamped “warren tool & forge co” “Quikwerk” “140”. By the way I don’t plan to keep it on that stand unless I add a piece of 2x12 on the bottom Long enough that I can stand on it. The leg is pretty secure in the hole I drilled in the wood. With the large mounting plate and leg in the wood and just the weight of this thing you can’t flex anything but the whole set up is front heavy and tippy without a longer piece on the bottom to stand on. The stand was something I had a piece of railroad rail mounted on but now that I have an anvil I don’t need it and it was already the perfect height so it was a good temporary place to mount it. I want to mount it to my bench but I still might hunt down a 4” leg vise for the bench.

-

Is this 160# fisher anvil worth the asking price?

Hines replied to Hines's topic in Anvils, Swage Blocks, and Mandrels

Thanks for the tips. I did do some research before I realized a piece of rail is an option and I did find that some people suggest to mount it vertically to get more mass under the hammer. But at this point I spent so much time going back and forth on what to get for a stand and how to mount things I probably spent a week thinking about it and hesitating to commit to one set up of the other. So I just said screw it I want to freaking hammer something. No more thinking about it. I need to throw something together. So I bolted it down and went for it. Plus to me it felt more comfortable having more surface area under my material for now. Maybe I will switch it in the future. But I still plan on getting something better for an anvil. Also, I know rebar isn’t the best material. But concrete crews leave it laying all over the job site so it was something free to practice on. I did find a salvage yard by my house and I bought a few different kinds of material to try making tongs out of. Some 1/4” x 1” flat stock mild steel is what I have to make my next set out of. I ended up using the rebar first because of it being the worst option. I wouldn’t care if I messed up. I didn’t want to waste my better material because I didn’t know what I was doing yet. Also because it was my longest pieces of material I was able to keep my hands far enough from the heat. After watching multiple YouTube videos I wasn’t too confident I would be able to remember all the steps of the process when I go to do it. So I figured I would try first on the rebar and see if I can even remember the steps laid out in the video. I figured somewhere along the way I would probably learn by mistake, throw them out, and move on to the better material when I have it figured out. I know they still look like flat jaw tongs but I was going for something close to a v bit or wolf jaw type of tong. I haven’t finished yet. I plan to shape the jaw more tomorrow and give it more of a groove with a chisel or a piece of square stock so it can hold everything a flat jaw can plus some round stock or square stock by the corners maybe depending on how much range they have. I didn’t want to spend $50 on a set of tongs knowing I would need more than one. So I figured I might as well try making them. I found a railroad spike one day while walking the beach not far from the railroad and I wanted to forge something out of it so I need something to hold it but vise grips of channel locks won’t do the job without burning myself. I tried holding them between my legs but when it’s flat on my anvil the angle of the jaw points the reigns towards my chest. I had a hard time getting the jaw more parallel with the reigns but also inset enough for both jaws to be touching. After holding the two pieces together at the bosses and sliding them around to figure out what direction things need to go I realized that I’m pretty sure if the boss was further forward closer to the jaws I wouldn’t have this problem so much. Tomorrow I’m going to try making some more adjustments before I pin them together. I will look for JLPservicesinc’s videos. Thanks again for the advice. -

Is this 160# fisher anvil worth the asking price?

Hines replied to Hines's topic in Anvils, Swage Blocks, and Mandrels

Just an update in case anyone is interested. I never ended up using the steel plate. Someone on Craigslist had a piece of RxR For $20 and they delivered it to my house. So I went with that. Btw I wasn’t the one that did the grinder work to it. I’m still on the hunt for something with a little more mass but it will work for now. As for the fisher anvil... I tried to negotiate a little bit better price and he pretty much told me to F off and instead of coming down on the price he changed the price on his ad from $390 to $450. Anyways here’s a picture of what I have set up for now and how I set it up. Plus a picture of my first project... a set of tongs that I’m making without any tongs to use. They still need a little more work bending into shape but they’re close for as far as my skill will get me for now. I wanted to use a chisel to put a groove into the surface that holds the material but I can’t quite get it without an extra hand. If I put the chisel in a vise and put the tong jaw on top of it I start to feel uncomfortable like I won’t keep it center. With everything upside down and not being able to see if I’m center it doesn’t feel right. It might help if I kept my jaws a little more square when forging. I’m sure I’ll get the hang of it with practice though. -

Is this 160# fisher anvil worth the asking price?

Hines replied to Hines's topic in Anvils, Swage Blocks, and Mandrels

Turns out there’s a weld shop about a mile from my house. I got this 30 pound chunk of steel for $20. It will hold me off while I look for something better. This way when my forge shows up next week I won’t feel rushed to find an anvil and end up spending way too much money on the first pos anvil I find. I have to figure out a way to mount it to something and maybe a stand of some sort but it should do for now. Thanks for the advice from everyone I appreciate it. -

Is this 160# fisher anvil worth the asking price?

Hines replied to Hines's topic in Anvils, Swage Blocks, and Mandrels

I’m definitely trying to find an alternative. The only thing I haven’t done is gone to a scrapyard. I just need to find one that lets you walk around and buy things. The only scrapyard Ive been to I didn’t think they let you do that. -

Is this 160# fisher anvil worth the asking price?

Hines replied to Hines's topic in Anvils, Swage Blocks, and Mandrels

Ok I looked At the nimbas and now I get what you’re trying to tell me. But I was never stuck on the London pattern. That just happened to be the 2 anvils I was choosing from. I don’t care if the pattern looks like a nimba or a London style but the nimba is $900 for a 120 pound anvil. I’m looking for an anvil in any pattern that’s no more than $400 and something with a hardy and pritchel hole. The NC just happened to be the only thing that checked those boxes without having a broken heel and being covered in weld fillings lol. -

Is this 160# fisher anvil worth the asking price?

Hines replied to Hines's topic in Anvils, Swage Blocks, and Mandrels

A year ago I was working in a machine shop. I wish I would have thought about it back then. But I do like the idea of being able to use hardy tools. I’m not arguing with you about saving some money and going simple though. I just don’t have anything heavy, flat, and made of steel laying around. I’ve asked everyone I know to keep their eye out for something and I’ve been watching craigslist and OfferUp for something. I don’t know maybe it’s the whole covid thing that’s making it hard to buy things right now. Seattle is a crazy place right now. I will check out the nimba anvils right now. Thanks for the tip. -

Is this 160# fisher anvil worth the asking price?

Hines replied to Hines's topic in Anvils, Swage Blocks, and Mandrels

Lol I didn’t know heeless anvils were so common. Well maybe I can get him to come to his senses and talk him way down in price. If it passes a bearing drop test it would still be nice to have a decent size anvil that doesn’t make as much noise. But only if he comes way down on the price like less than half. I doubt that will happen though. Here is the NC anvil I’m looking at. It’s $335 but who knows what it costs to ship. I haven’t got that far yet. I’m just having a hard time finding anvils in my area and at this point I’m close to using a piece of Railroad rail. I have a feeling I will be happier with the NC than the RxR. There is more anvils in eastern Washington where there is more farms but I’m not going to drive 3 or 4 hours to look at an anvil. -

Is this 160# fisher anvil worth the asking price?

Hines replied to Hines's topic in Anvils, Swage Blocks, and Mandrels

Ya he messaged back and said it was 192 pounds and now it’s 160. So it is missing the heel. Sorry I never noticed the read this first link when getting started. I’m located in snohomish Washington which is just outside of Seattle. Also the price of the anvil was in the pictures he wants $390 for it. I will make the edits. -

Is this 160# fisher anvil worth the asking price?

Hines replied to Hines's topic in Anvils, Swage Blocks, and Mandrels

I’m glad I asked. I didn’t even notice it was missing the holes and possibly missing the heel. Thanks for the input. -

First of all I’m new to blacksmithing and I’m new to this forum. Thanks for having me. I’ve been planning on getting a forge and all the tools to get started smithing for quite some time now and one thing I underestimated more than anything was the price of an anvil. I can see that this anvil doesn’t have the best edges and it has a good ding or chip in the face. It also looks like it might have a couple spots where someone filled a couple dents. It might just be the picture. I’m going to message him tomorrow to verify and maybe haggle. I know fisher makes good anvils and if it was more perfect I would probably pay the price. But if you guys think The amount of damage on this anvil will make me regret buying it then then I’m just going to buy a new NC anvil for the same price or slightly cheaper. I know an NC anvil isn’t the best but at this point I want to get started forging knives and tomahawks and I wanted you to know if it’s not this than it’s an NC.