-

Posts

139 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by wirerabbit

-

Thanks for the info, Les. Going to be interesting to try out. T

-

I've made Mark's tool for my small 30 kg anvil. Right now I've just got fullering dies made. Super simple, even for me! Because my hardy hole is less than an inch, I just used solid square bar. The dies are 1 inch square, and I took the time to case harden them after grinding the profile. When I make the tennioning dies, I am going to precut the stock bar then drill the hole. That will make the total height of the hole the dimensions I need. Much of the square corners will be ground off, and I expect my finished opening to be more flattened circle shaped than circular.

-

Slim, let us know how that alteration works and how it compares to what you did last. I can not speak to sideblast coal forging, but I do use charcoal in my small sideblast. I noticed that your tuyere is right down at the bottom of your bricked firepot. Do you know what series bricks you are using? If they are 3 inch, that might get the heart of the fire (with charcoal) just about where you need it. Be sure to notice that bit of information next time you use charcoal. For me, my bricked fire pot is 4.5 inches deep. I first has the tuyere just about a half inch from the bottom and I could forge things okay. I did have to dive a bit to really find the heart, but I made all my first tools and tongs no problem. Now I have moved the tuyere up maybe 2 inches and have much better access to the heart of the fire. Remember my forge is for charcoal. My suspicion is that coal will not like a side draft firepot that is optimized for charcoal, but I certainly could be wrong. Looking forward to reading more about your experiments in both coal and charcoal. I'd love to know how the charcoal and coal fires differ with the same set up. Would be instructive. If I get some time to run to goodwill tomorrow I'll pick up another cheap hairdryer and post the simple mod for a forge blower.

-

I like how you're trying everything, figuring things out. That is going to be the best learning experience for you. I suggest that you convert your hairdryer to dc power with a controller. The motor should be a dc motor that you can run off of a 12 or 18v battery pack . You will get much better control of your air. You might even find that running the hairdryer at less than "low" will get that charcoal to work great for you. With the controlled dc motor and an appropriate battery pack, you'd still have all the power to keep that coal working for you. If you want to try the mod, I can talk you through what I did with my dc blower, nee hairdryer. I'm currently using the 18v battery pack from my power grinder. Found a very inexpensive controller in the interwebs.

-

Why is anvil rebound important?

wirerabbit replied to rdennett's topic in Anvils, Swage Blocks, and Mandrels

Here you go. Enjoy. https://calsmith.org/resources/Documents/Technical_Documents_Page_Files/techdocs_thephysicsofanvils.pdf -

Ceramic crucibles

wirerabbit replied to Nobody Special's topic in Smelting, Melting, Foundry, and Casting

If you are making crucibles, you need only fire the clay once, but the rate of temp increase must be slow during a few crucial temp. ranges. I'm not surprised that you did not have much luck firing Hobby Lobby clay in a forge, George. Too hot too fast or it was not a ceramic clay. The internet will supply you with the details. Many "clays" used in crafts are clay in name only or have fillers that can render them useless for our purposes. -

Now I have to go out to the forge and check my bags of charcoal for little holes and missing coal!

-

This is a Vevor forge and will work just fine. You may be right, Mikey, about the burners. I have still used only one on mine and have had no problem melting small curls off my s hooks! You are seeing a small handle between the burner retention sleeves rather than a pipe. I have been running mine for several hours now and am still using the simple red-nobbed regulator that came with the kit. I set it at 1.5 rotations and leave the air shutter at about half way. I'm sitting at 400 feet above sea level and and pulling from a 33 lbs tank. Full disclosure, I have not really spent the time to dial in this forge, so no fiddling with the primary air or blocking off ends. I fire with both ends open, one burner, and a slight flame out the front. I'll put my charcoal forge up against my Vevor forge any day, but sometimes you want to experiment with longer heats, etc. It will do. Mikey's suggestions for improvements might be an option I take up at a later time. For now it's good enough. Enjoy Pigsticker. Taylor

-

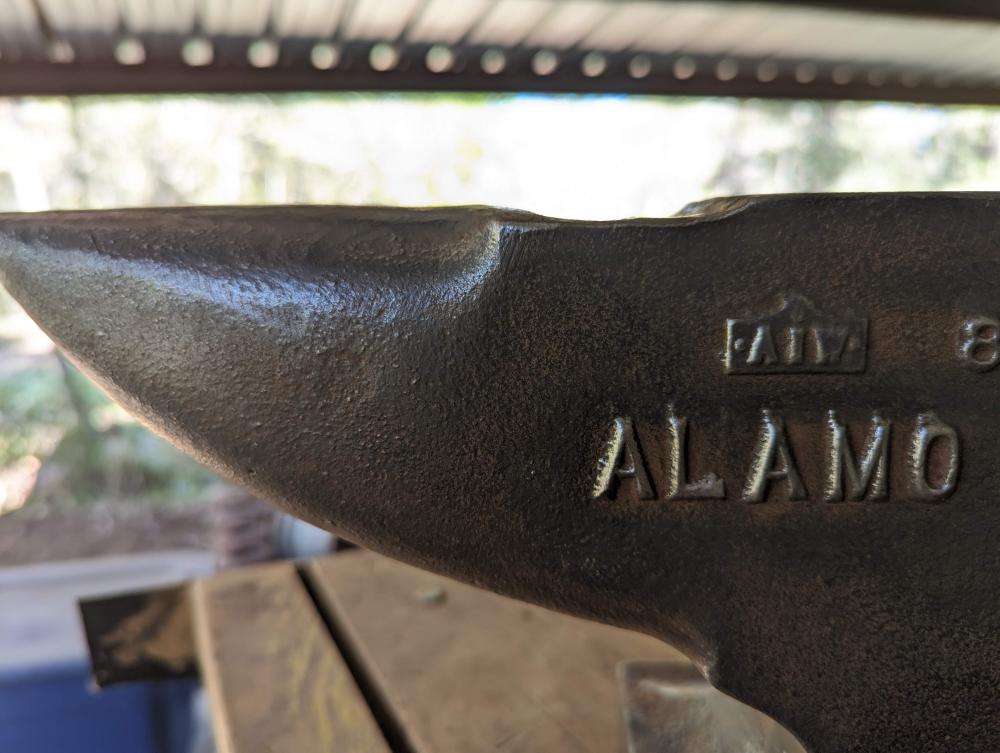

This is the chubby horn the Alamos are known for. But what's up with that crazy cutting table? 3 1/4 inch wide face, 10 3/4 inches to the step, and another 6 inches or so of horn. Hardy hole is 7/8 of an inch and the pritchel hole is 5/8". Lots of casting flash at each of the corners inside the hardy hole probably from a defective or misaligned core. Some minor markings to the face. Interesting holes there near the right edge. Check out that nice corner. Hammer rebound is the same as my Acciaio 30 anvil.

-

Was gifted this nice little (75lbs?) AIW (Alamo Iron Works), a Texas born anvil. Sorry for the quick picture. I'll do some wire brushing and take some better shots. The horn is more flat than conical, and the heel is quite beefy compared to a London pattern, but should make a nice narrow-faced addition to my shop. I do not have a copy of AIA, so I can't tell you its composition, but it is in very good condition from my quick examination yesterday. Some oddness with the cutting table which looks like a machining error?

-

My initial thought is the positives as you have stated them do not out weigh the negatives. In addition to the spark ignition danger, you risk failing to entrain all the fuel gas into the forced air volume, which would come with a few more negatives. Fuel gas injection down stream of the forced air will mix well if designed correctly. I am also not convinced you would reduce any piping with your hypothetical design. Fun to speculate, but this might be a solution looking for a problem.

-

Super easy. Check out the many, easy versions you can find online. All you will need is a plane of glass and a box. No lensing necessary. Let physics do the rest.

-

Have you tried making a solar melter to process your wax? You can decant off quite a bit of the unwanted sludge by putting your cappings in a bit of water. When the sun melts the wax, it floats and pouring off the top through a rough screen can clean up the wax quite a bit. The water will dissolve much of the honey as well. Saves you lots of cheese cloth when you do it the second time.

-

I was going to suggest looking for an old water heater, but that will do just fine, won't it? I don't know if it is just my specific situation, but I have never needed a hood for the small charcoal forge of mine. The only time I get smoke or fire fleas is on start up and that lasts for less than a minute. Of course, you've done this before, so you know what you're doing, but I'm curious about your experiences with charcoal and hoods.

-

Josh: In what part of Southern Germany was your apprenticeship? I enjoyed living in Germany for several years and remember it very fondly. I'm just a hobby blacksmith myself and only have an inexpensive and light "VEVOR" style (not marked but the exact same pattern) anvil with a double horn and I have actually discovered the great straightening use of the square horn simply by using it. I'm so glad you mentioned it as a function. It's not easy to figure things out on your own. Alas, my anvil pattern has a rather ugly step from face to round horn, and I look on with envy when I see that sumptuous transition of a beautiful German anvil. What you say regarding anvil edges make a lot of sense. 1/8" with chamfer sounds good. My poor anvil came with a terrible, ragged edge from the milling machine. No clean up that I could tell. I 'eased' that severe edge as little as possible but did add small areas of the face near the horn with larger curves. This is a very common suggestion for new diy-ers. Once you take it off, you can never put it back is often the counterpoint. I will be focusing my next few tong making sections over the more "crisper" edges next time. Thank you.

-

What did you do in the shop today?

wirerabbit replied to Mark Ling's topic in Blacksmithing, General Discussion

Savlaka, I'm diggin' the unwelded blending of the twist at both ends of your rake handle. I like to see things that make me think "that was mushed together. I have the small bar to attempt my own basket twist handles for some pokers etc, but I don't have any flux. I think I might be able to find some borax in the clay studio. I use if for low fire glazes, so it too is a flux in the ceramic kiln. Have you ever tried using the chacoal ash as a flux by any chance? I thought I might try that. I finally retired my charcoal rake made from rebar for a nicer, round bar model with ball end. Now it almost matches the scrapyard carriage bolt I forged into my firepot poker. I'm so junkyard. -

What did you do in the shop today?

wirerabbit replied to Mark Ling's topic in Blacksmithing, General Discussion

Most excellent, bluerooster. That'll do. I'm glad I use charcoal and after things light up, no smoke! I always thought those side draft hoods were the best solution for coal forges that need a hood. The overhead hoods seem to be a really good place to bang my head. T -

What did you do in the shop today?

wirerabbit replied to Mark Ling's topic in Blacksmithing, General Discussion

I thought I'd experiment with simple twists and manipulation of the bar stock before twisting up to see how punching the bar affects twist. That was enlightening. Then I thought, "That sure is a bunch of 1/2 inch square bar. I should do something with that." It was a great opportunity to practice tapering on the face of the anvil, drawing out on the face of the anvil and the horn ( much easier and faster on the horn for me), and scrolling up a round point with the hammer. Improving. What else should I practice? Turning on the horn! I set to making s- hooks, and I learned a little bit about work flow and order of forging. Those s-hooks are the first three. I think the later ones were better. Now I'm counting the blisters on my blisters. -

Savlaka, I'm glad you're branching out into charcoal forging and wish you success. I love using charcoal in my small side draft forge. I use it when I need a short heat and use my two burner propane forge when I need to either heat up a larger mass of metal or a longer heat. I'm still learning, so take my comments with a few grains of salt. I have forged over half my current tools ( punches, chisels, tongs, hardy cut, etc) in my charcoal forge, so I know it works well. The original reason for me to buy an inexpensive propane forge was to hold me over until I could make some new modifications to my charcoal forge. HA HA, I made the modifications to the forge in less than and hour and was forging with charcoal immediately. It heated 1 inch square bar quickly. I have read many many posts on this forum about the particular needs of charcoal as opposed to coal/coke. Many folks swear by side drafting of charcoal instead of bottom drafting, but others have had no problem with bottom drafting charcoal. Tons of suggestions on the height of the fire as well as how deep the fire pot. All are good starting points, but nothing beats performing your own experiments! When you want to discuss the results of your forge, I'd be happy to participate. My suggestion for right now is to leave everything as alterable as you can. I have a feeling you are going to want to change some things, so don't cast your fire pot with expensive refractory until you know you have the dimensions, location, and air input the way that actually works for your fuel, your projects, and you. I'm looking forward to seeing how things progress. I may be making some changes to my charcoal forge in the near future myself.

-

Natcova, I forgot to add a link to a comment that shows my set up with a controller, battery, and dc motor source. Don't let the subject title fool you: my forge is not a JBOD anymore. I've move passed that, but the blower info is apropos. Good luck and feel free to ask more questions.

-

It might work, Natkova. I tried to find out what a standard hair dryer puts out in volume of air, but the numbers are all over the place and who knows if they are accurate. If I had to guess, an inexpensive hair dryer (what I use for my charcoal forge) puts out roughly 50 CFM, which if this English Major knows how to google, is 1.4 m3/m. That can give you a good starting point. Run it at just under half speed and see if it is too much air. The variable speed control will be very nice if you get the blower to work. If you're handy, you might think about wiring in a toggle switch for on/off. That can save as much as 50% of your charcoal. How familiar are you with running charcoal for forging?

-

From what I have read on this forum, such a blower is way over powered for our purposes. I have a charcoal kiln with a 3/4 inch tuyere side blast, and I use the dc motor and fan from a hair dryer. My controller has never been set for more than 50 percent on an 18 volt battery. Leaf blowers like I see in your picture put out way more cf of air than the hair dryer motor. Still, you could certainly use it if you could use only a portion of the cf produced via either a waste gate or valve set up. My thinking is, if it's free, you should at least try it. You will learn quite a bit no matter what happens. If it is going to cost you, I'd do a bit more research to be sure it was suitable. T

-

What did you do in the shop today?

wirerabbit replied to Mark Ling's topic in Blacksmithing, General Discussion

I'm diggin' the ice cream scoops, Chad. Of course these days I'm an ice cream sammich fiend, but one of these days... I'm just now starting to practice twists. Man, you have to pay attention as just a quarter turn makes such a difference! Savlaka, my punches, chisel, etc. are nowhere as refined as yours, but I will have to make more soon. I used sucker rod and they are just not tough enough. So much to learn, so little charcoal. -

What did you do in the shop today?

wirerabbit replied to Mark Ling's topic in Blacksmithing, General Discussion

Have combustibles will forge! Taking my new tongs for 3/8" bar for a spin! Ignore those HF needle-nose pliers, please. -

You might be talking about Flow. I'm not sure if that is what you are experiencing, but the start of your story sure sounds like the exact opposite of Flow. Check it out on the interwebs. Mihaly Csikszentmihaly is the man who wrote about it first. When you drop into Flow, it is a wonderful thing: time stands still, you are super focused, and at ease.