Gillie

Members-

Posts

9 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Southern Illinois

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

I think what I will do is leave the one I have like it is since it does hit a good forge temp and metal is easy to work without killing my arm swinging a hammer and just get a small roll of kwool and make a second that I will try with more wool and get some of the ir reflective coating that was mentioned. Scared if I try screwing with the one I can at lest forge with it will become useless lol. I have everything to make a second one and when I make it smaller like you all recommend I’ll have way more then enough everything else without the kwool and frosty I don’t think your saying anything wrong at all. I would rather have more facts from others and what’s working for them so I can try and get what I need out of all of it and make something that works for what I need. So please by all means speak your minds. I promise I will not go cry cuz I didn’t get my way lmao I’m old school tell it how it is :-D

-

Ok as for frosty’s first comment I do pass back and forth for my larger knives I have made so I don’t burn the metal to sheet lol for smaller ones it don’t take long there in and out in no time with not much scale build up at all that’s why I say good forge temp. Although I could be wrong I don’t know for sure. As for the tubes being placed into the air not with I was having some problems with it and tried just to get the mix better and it seemed to work out for me for forging. Again can’t weld but forge and heat treat not bad at all. irondragon I do have a shop vac I could try and see if that is the problem thank you frosty. I tried the biggest and baddest inflator I could find that was 120vac and as for the air flow the blow dryer puts more water column then the 30$ Inflator we already had. But I will try the shop vac and see if that can push a better static pressure and a better mix. Also I will try making a forge with more kwool and less refractory just cuz atm I’m home and board af lol thank you all please keep the comments coming because I have the tools and mats will make new stuff I’m board right now lol I actually think I’ll go try the shop vac and see if it pushes enough static pressure to really make that thing glow just cuz I’m board irondragon I’ll let ya know. If not we’ll it’s new forge making time then I guess I actually think I’ll go try the shop vac and see if it pushes enough static pressure to really make that thing glow just cuz I’m board irondragon I’ll let ya know. If not we’ll it’s new forge making time then I guess ooo frosty reason I put them facing into the wind was I seen people that had somewhat the same problem and just put the gas into the wind and it mixed better so I tried it and for forging heat worked out just not for welding heat

-

I have made a few longer k-bar like knives for friend. I’m in the military and everyone wants k-bars so that’s why I made it 18” so I could make a 10” blade with a 5” hidden tang for my comrades. Only reason it’s that long

-

I was out for a bit more then an hour trying to get it hot enough to weld and sorry didn’t realize that’s what the quote button did sorry

-

Have high temp refractory and kwool liner of 1” I still have all kind of kwool and refractory also plenty of metal I could make another and try that and see. If you all thing more kwool less refractory May bring it up to the welding temp I need I’m game. All kind of stuff to make another forge around still

-

I have 1” kwool then 2” of refractory cement. I use kwool for the back till it’s nice n hot then I remove it and get everything tuned for forging. I left the kwool in on the back when I was trying to get it hot enough to weld tho

-

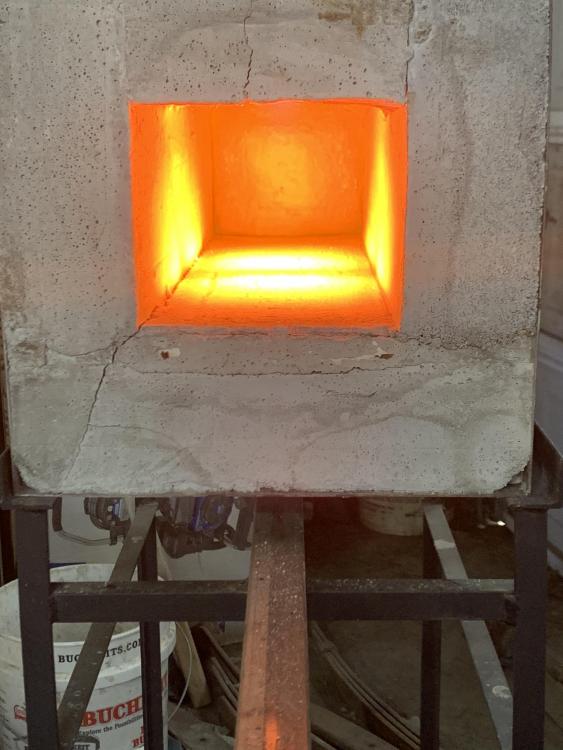

3 inches and yeah I’ll fire it back up and try to get some pics then

-

No but I’ll get some soon as she cools off just got done trying to get a welding temp

-

So I’m new to the smithing world been doing lots of research and what not way before I started to try forging. Now I have made a pretty good forge hits a grate gorging temp can bring it down to a good heat treat temp. But I just can’t seem to hit that welding temp I need to try and make damascus for some reason. Forge is 18” long and 5” x 5” wide tall in the forge. Using a forced air system I have refined a few time it is all 1 1/2 pipe with 2 to 1 1/2 to 2” reducer fittings with a star pattern in them with 7/32 in the center 5/32 on the first loop and then 1/8 on the outside loop all holes are spaced 1/2 apart from center and I drilled them at a 10* angle on the first and second loops center is flat drilled. Using 2 20lds propane tanks for each burner with a 0-30 psi adjustable fuel pressure. Have to gate valves for the 2 tubes from the forge to the first 90 is 6” then 12” to the next 90 where I have my propane feeds at facing into the wind and then 12” to the blowers. Each blower is around 200-250 cfm. If anyone has something set up like this that can hit a welding temp would love to hear from you. Like I stated before I can make a great forging and heat treat temp just can’t seem to hit a welding temp to save my life for some reason any help I can get would be much appreciated thank you