Selph

Members-

Posts

34 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Selph

-

I just started to look into this again (and found this old thread!). The pandemic did indeed hamper my ability to do much, but it was more the remodel for my FIL to move in with us that put things on hold. It took almost 2 full years of fun stuff like this away from me. I will put some effort into keeping track of exactly what I end up doing. I should spend more time here now that I can work on stuff regularly again. This is the best source of blacksmithing information on the internet, in my opinion. I'm hoping to order steel tomorrow or the day after, so I'll end up settling on something here soon. Or I suppose I could order the steel for the forge build first and then figure this out afterwards. I'm trying to figure out now if I should go the big route and use a 55 gallon drum or if making a series of medium-ish batches makes more sense for me. That decision will probably dictate exactly which direction I go. I do have an old hot water heater we just replaced in the basement that could potentially be salvaged, I'll have to see if others have done that and what it entails.

-

Building a more permanent charcoal JABOD

Selph replied to Selph's topic in JABOD - Just A Box Of Dirt

A charcoal retort or something is in my future probably. We live on a very wooded lot with almost exclusively hardwoods and just downed limbs and dead trees would provide me with all the charcoal I would ever need. The issue being I've got a project list a mile long and my wife doesn't feel like "charcoal retort" gets me closer to finishing stuff. Most of it is red oak, white oak, and cherry. Are there any versions that are decently efficient without taking too long to fabricate? While I'm welding together the new forge, I could probably sneak something else in too. -

Building a more permanent charcoal JABOD

Selph replied to Selph's topic in JABOD - Just A Box Of Dirt

Oh, another question is: Side draft hood or a standard hood for a side-blast charcoal forge like this? I was thinking standard would do better with all the sparks, but I've never used either of them or even seen them in real life. Thanks again for the feedback, everyone. -

Building a more permanent charcoal JABOD

Selph replied to Selph's topic in JABOD - Just A Box Of Dirt

Charles, thanks for the input! Right now I'm working with more of a trench, I've been thinking about using more fire bricks this time to create a more confined and defined space for the charcoal. I think that might help me be a bit more efficient with my fuel usage. If nothing else though, I know the trench-style I've been using has been working for me for a while, so if the more boxed in space doesn't pan out, I know it'll still work. Frosty, I really appreciate the compliment on the box bellows. I made them fairly quickly, but I've been woodworking longer than blacksmithing and I did want them to look nice. Also, I'm a bit embarrassed to admit it, but I'm not sure I ever understood what you meant until just now. I apologize for being dense on this. You're talking about that big air gap between the bellows and the body of the forge itself, right? The only reason it's there is because I didn't want to cut the pipe for the tuyere and regret cutting it. That and paranoia about protecting the bellows. I could make that substantially smaller, you're right. How small? I'm not exactly sure, to be honest. It's at least a foot right now, as the tuyere is 18 inches. Maybe I could drop it to a 6 inch gap? I assume I need a bit of air in there to keep the tuyere cool, but maybe less than the 6 inches I'm imagining right now. It's getting cool air run through it each time I use the bellows. For the bosh, I've now found two different definitions online. The first one I saw was essentially a slack tub attached to the forge body. That's honestly a no brainer and I don't know why I haven't done it. The second definition I've seen out there is for a water cooled tuyere essentially. For that, I found some instructions on the calsmith website (I'm not sure I can post links, so I'm avoiding that), and I'm guessing that's what you're talking about. I could do that to shorten the gap there to just a couple of inches probably. Basically, bellows, then 2-3 inches of water tank, then make the steel end of the tuyere mate to a Kastolite 30 or something tuyere/tunnel thing that actually feeds the fire itself. This might keep the steel from being used up and I can replace that cast refractory segment as needed. That sounds really interesting and fun to try and make. -

Building a more permanent charcoal JABOD

Selph replied to Selph's topic in JABOD - Just A Box Of Dirt

I'm amazed you would remember those posts. On the partition, are you asking why I'm doing it to this forge? You're probably right that it's too much room. I didn't want to make it too small and regret it, but being too big isn't ideal either. The current box I have is 20 inches wide, but only 13-14 of it is usable past those fire bricks. The newer iteration I was planning on having less dead space and shortening the tuyere a bit. I was thinking a 24x24 footprint wasn't too bad. Of course, the bellows will still stick off to the side, and they're 33 inches deep, so I'll have to take that into account too. I had to look up the bosh, that's a pretty good idea. I could drop the width down to 18 inches and add one of those. That's four extra inches to hopefully make it so I stop knocking the charcoal off the table or having the fire spread to the charcoal that's waiting in reserve. It's possible that the better solution would be to just make my own charcoal. The charcoal I'm using comes in pretty large chunks and it's hard to get it stacked up well and under control. That's why I feel like I need more space for the charcoal and whatever else. If the charcoal were better sized, I think I could just keep a scoop nearby for topping off the fire. For steel, I had been thinking of using 1/8, but maybe I could just use 3/32 or something. I appreciate all the feedback! -

Building a more permanent charcoal JABOD

Selph replied to Selph's topic in JABOD - Just A Box Of Dirt

Yeah! It is a box bellows. I looked at a couple of videos online and just kind of made one off the cuff. I'm mostly a woodworker, so it was a pretty easy project. It's double acting and I love it. It's super quiet in use. You just hear the wooden valves click-clacking and the whoosh of the fire. I've forge welded with it no problem. More than enough air. I've honestly never used anything else at home. When I first started I took a class with someone else and they had an electric blower with coal, and that was nice too. I kind of like having something to do while heating up the steel. Keeps my attention on the task at hand. I could probably take the top off and take some pictures if someone wanted me to. And yes, that was kind of the impression I got. That more or less anything can work, it just depends on your personal style and how you do things. I'm not changing a ton from how I had my forge before, but just making a few tweaks here and there. I do like being able to reform my bowl if I want. But I want to remove as much fire risk from forging inside as I can. -

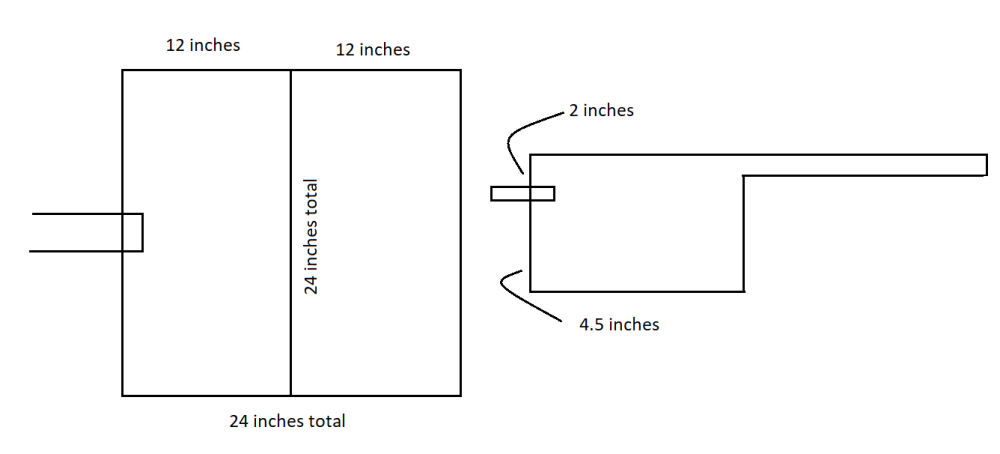

Hello again, everyone. I've been forging for almost two years now with my JABOD. I owe a lot to all of your help with that project and getting me started. Well, in the meantime we built a detatched garage with a separate room in the back with the idea that I could forge in there. Here's my current set up that I've been using up until now. I've been working outside and pulling it inside when finished working. That garage in the background is now living space. My father-in-law has had some serious health issues and moved in with us, and we needed space for him live which is what prompted the new garage/remodel. Well, now that I'm ready to move this into a more permanent location and about to have a chimney installed for it, I'd like something that's a bit better constructed. Ideally out of steel. I'm a little concerned that over time the wood could become pretty flammable with pyroloysis, and I think the depth on this isn't quite what it should be. The bottom gets really warm after each forging session. I just wanted to run my idea past people who would know if I'm being crazy. My idea was to weld up a table that looks like this: Does that seem reasonable? My current table is something like 17 inches square, and I find myself wanting some space to pile up charcoal. I really like the ability to reform my bowl to whatever shape I need with the bentonite/sand mix I saw in the JABOD threads. My idea was that if I make that 12*24 section, I could reform it to be anything I need with all that space in there. Then I'd have that upper shelf which may only be an inch or so deep to hold charcoal/tongs/whatever while I'm working. If I'm doing something long like large knife (I've got an 8 and 5 year old), I could always split the tuyere and have two coming into the bowl. My tuyere is 1.5 inches in diameter (much bigger than I've seen recommended, but it works really well with my bellows), so the overall depth would be about 8 inches. If you all want, I could take pictures while I build whatever I end up going with. I also need to decide between a side sucker/hood for the smoke/sparks. I feel like the hood might be better for catching the sparks, but I have no experience there. Thanks for all the help.

-

Wikipedia isn't that bad of a reference. It's great as a first pass and a place to get additional sources. Also, on any page that sees a lot of disinformation or editing from large numbers of non-experts (generally politically controversial topics), they tend to lock it down. Not everyone can edit it, and you need a certain amount of positive work within Wikipedia itself to attempt a change.

-

That's an awesome memory. I love it.

-

Charcoal Forge: Laying steel plate or refractory brick on work piece.

Selph replied to MJTX's topic in Solid Fuel Forges

Don't worry, I'm in the same boat. Just starting to blacksmith, and just starting to weld. To be fair, I've wanted to do both for a long while. And I have a list of welding projects already that's surprisingly long. We've got to start somewhere, right? Sometimes knowing that you need to ask a few questions of people who know infinitely more than you is the best way through. -

Just a box of dirt, or a simple side blast forge

Selph replied to Charles R. Stevens's topic in JABOD - Just A Box Of Dirt

Oh, okay, great information then. I may have put in too much kitty litter., but I could always add more sand. I just checked on the mixture I currently have and it's definitely a bit dry. It doesn't compact at all when I grab and squeeze it, just kind of crumples apart. I think I'll add maybe another 2 cups of water, mix it in, and wait another day to check on it again. Right now I've got half a 5-gallon-bucket half full of my mixture, so 2 cups shouldn't be too much. I can't really do much with it right now anyway, we're getting our routine April snows right now and it's only 20 out. -

Haha, nope! If I'm going to do something, I tend to really commit. Thanks for the compliment on the box bellows. I actually milled all of that maple myself from a tree that died at my dad's place. Then I resawed it, flattened it, did all of that good woodworking stuff with a combination of hand and power tools. At some point, woodworking tools is something I'd like to really get into making, though I plan to start much more simply than jumping straight into forge welding tool/high carbon steel bits into mild steel bodies for tools. And yes, those are IFBs, but I'm already trying to move to something else. I had, uhh, purchased those kind of in error a while back. I decided to use the broken ones here as a one-off to see how well things worked and to get a sense for where exactly my tuyere should be and how large I should make my trench for the charcoal. I've got some sand and kitty litter sitting in a bucket right now to make adobe that I was hoping to use for a more permanent forge setup. Maybe tomorrow if I got the ratios right. I followed the advice here as best as I could, but it looks really dry right now. The sand I dug up was a bit wet though, so I only added maybe 2 cups of water to my mixture. I'll see tomorrow if I need to add more I guess.

-

Just a box of dirt, or a simple side blast forge

Selph replied to Charles R. Stevens's topic in JABOD - Just A Box Of Dirt

With my bellows and forge dimension test run through, I'm ready to get going on a better setup that isn't just insulating bricks. A few questions though: The adobe mix I've seen is roughly 20-30% clay, with the rest sand. We've got pretty sandy soil, so I'll just dig up some of that for my sand and use kitty litter for the clay. The sand will probably be a little wet since it rained a couple nights ago and has been cold, so from other places in this thread I should probably only add 1-2% of the total weight as water, right? Then let it sit overnight and check in on it in the morning? For the box of dirt itself, is it okay to use some of these cracked insulating bricks to form a structure that I mold the clay over? I figured it would give the wooden frame a bit more space and protection, and since they're cracked, there's not much other use for some of them. Then, do I need to wait for the mix to dry naturally or can I use it right after I'm done forming? Lots of questions, thanks for all the advice so far! -

Yeah, very. I was a bit worried about the wooden valves, as I've never done anything like that before. No reason to worry though, it works so well. I could blow the charcoal out of the makeshift trench if I tried to. If anything, I actually think I made the bellows a bit too tight. I've got two bags of sand under the bellows there because it does take a bit of force to pump right now and I wanted to be absolutely sure the hot coals didn't get tipped over. I'm a bit tempted to go in there and take some shavings off the internal piston, but I don't want to take the fabric off and go through all that. Plus, I think it'll tend to loosen up a bit over time. I was amazed at how hot it got with just steady, constant air. At one point I wanted to see how hot I could get it, and it easily turned the end of that taper into a sparkler. Which I know isn't good for the steel, but showed me at least that charcoal and these bellows are easily able to provide the heat I need. Pretty pumped. See? Pumped? Bellows? I'll show myself out...

-

For what it's worth, I'm finally symptom-free. In 72 hours I'll be legally able to leave my house again and follow the less strict shelter-in-place. Which is good, because the grocery situation is getting a bit challenging. I also felt well enough yesterday to finally test my box bellows with a very temporary forge. Moving my anvil and stand with some castors made me less out of breath than just walking up a tiny hill a week and a half ago. Pretty crazy.

-

Out of the gate, I know this looks a bit sketchy. I wanted to test out my newly-made box bellows, so I made a temporary set up to try things out. If I just so happened to move my anvil out there too so that I could move some metal for the first time on my own, well, these things happen. This next picture is after I let it burn down a bit. I really didn't have anything I wanted to work on this time around. I just wanted to see how well I could heat up the metal. I basically just tapered a piece of 3/8 square bar. And a bonus shot of the type of anvil. I found this on craigslist back in January. I ended up paying $3.25/pound, but it came with the stand which fits it perfectly. Excited to finally heat some metal up. Maybe today I'll try to make some tongs without tongs.

-

Is there an agreement around here about which types of charcoal retorts work well? I saw the Hookway thread, and there's a few others around that I looked at. I've got a lot of wood scraps from milling up logs and taking care of the woods at my parent's place (and our own baby woods). Not looking to make a ton at once, more along the lines of medium-sized batches.

-

I'm definitely a bad negotiator. I have no idea how to do it. I ultimately just set the price for something I'm buying or selling before the transaction, with like a 5% wiggle room. If the other party and I don't match up, I'll just walk. I'm not an outgoing person anyway, doing anything more than that is too stressful.

-

Yeah, this is absolutely true. I talked to a public health nurse after my test came back, and they think I got it from my father-in-law. He's had some health issues and last year we moved to a new house so he could have his own space but live with us. Anyway, he had pneumonia back in February and was in the hospital for a week. He came home literally the day before we started isolating, which was 3 weeks ago at this point. But he had a terrible cough and probably gave it to my wife. She finally got a cough and some mild cold symptoms almost two weeks ago on Wednesday. Then I came down with my initial symptoms a bit over a week ago on Friday or Saturday. They didn't test my father-in-law at the time, because they weren't that aware of the virus yet, and didn't have the tests even if they were. But he had all the signatures of a rougher case of the virus. Cough, fever, pneumonia. We're hoping for an anti-body test soon too, so we can confirm if he had it or not.

-

I know I'm new here, but felt like jumping in. I'm only 36, but I ended up in the ER for 3-4 hours back on Thursday. Got the test while I was there, and came back the next day as positive. I'm in great shape (I'm a bike commuter year round 10 miles every day), but I have a long history of lung problems that were eventually fixed with surgery. Anyway, back on Thursday evening I walked up a small 10 foot hill in our driveway and from just walking up that hill I got so out-of-breath that I almost passed out. I continued to be light headed and needed to take 2-3 breaths in the middle of every sentence for the next 4-5 hours. Hence the trip to the ER! I've still never had a fever. Just a minor cough, and a very minor runny nose. On Thursday, I could tell it was getting a bit harder to breathe, but the weird thing is how quickly I lost my breath and then that it just got better after 4-5 hours. I'm obviously still sick now, but breathing has been getting easier again over time. A little bit better each day since. My wife has had the exact same symptoms minus the difficulty breathing, but we chalked it up to just a cold from one of the kids back before we isolated. I'm hoping to come out the other side here soon. Then I'd love to donate as much blood as they'll let me. And maybe then I can finally get around to making that JABOD forge...

-

What the two of you are describing is exactly how I got interested in blacksmithing. I couldn't justify buying some of the more unusual woodworking tools I wanted, but I could always learn how to make them... and a new hobby was born. Being able to make my own hooks, hinges, and the like is just the icing on the cake. I finished my box bellows today, and tomorrow I'm going to build my JABOD forge. Hope to be making my first things on my own this weekend.

-

What did you do in the shop today?

Selph replied to Mark Ling's topic in Blacksmithing, General Discussion

I saw this thread and felt like jumping in. Not metal, but related to blacksmithing and it is what I was working on in the shop a day or two ago. Almost done with the box bellows at this point, then a quick JABOD forge build and I should be able to try out my first couple of things on my own. Looking forward to it! -

I've actually been wondering this same thing and I had been leaning toward the oxy-propane setup with a separate welder. I have a few smallish fabrication type projects I've been wanting to do as well. Is there any chance one of the brands is better about making torches for oxy-propane than the others? I have a vague memory of someone saying that Harris specifically had good oxy-propane torches and that the other makers didn't have as good of options specifically made for propane. But that could be out of date or just flat wrong.

-

All of a sudden, my wife's quilting habits seem reasonable. I can only hope she has friends on quilting forums convincing her that all my hobbies are totally sane!

-

Oh goodness, I wish. I felt bad about buying my bandsaw and tablesaw until she bought one quilting sewing machine that cost more than everything in my whole shop combined. I've tried to sneak some thin boards onto that thing, and most recently some mild steel, but all it did was break the needle and she had to spend even more on repairs... Must have gotten a lemon or something, the thing appears no good to me at all.