-

Posts

16 -

Joined

-

Last visited

Profile Information

-

Location

Dayton, Oh.

Recent Profile Visitors

344 profile views

-

This is fun. Those are all great ideas! I read on one of your posts that you mentioned a gas forge that had an entire cavity that was essentially a ribbon burner. Now that sounds cool! A challenge I hope to see you undertake. I will probably start thinking of ways to incorporate some of the ideas you mentioned. Not to steal them. I had previously contemplated a replaceable tuyere myself when I decided on a side blast forge. Being a welder I deal with consumables on a daily basis. Hopefully you'll be one to appreciate the outcome of the efforts. Thanks for your help guys. I should have something fabricated by next weekend. Side note: Is there any benefit to a stainless steel tuyere and bosh? I know that the water in the bosh made with steel turns red from the iron. I don't think it continues to rust from the inside out. I don't think Fe is like that. It doesn't oxidize the same way it does when it's water like it does when it's exposed to atmospheric conditions. I really don't know, so if I'm wrong please correct me. So if the water isn't really the determining factor, then the ability for the stainless to withstand higher temperature without affecting the integrity might be helpful. Would it make it last longer? My real goal is to make a tuyere that will last longer and easier to change out. It can't be that hard.

-

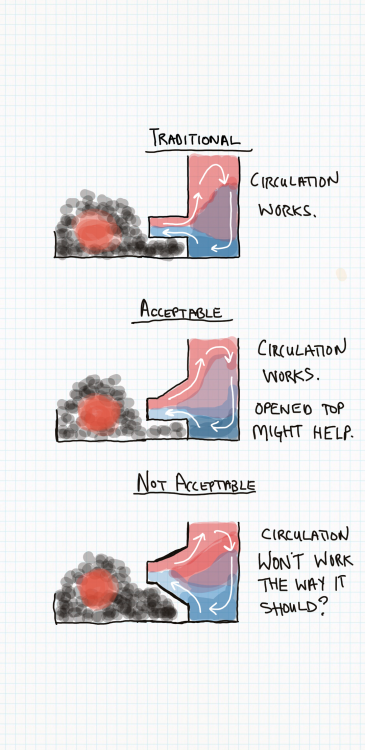

I've had to read over Frosty's and your post a few times. It's starting to make sense. I think. My brain was so convinced that giving the tuyere a more open access to the cold water at the bottom was good. So if I understand you guys right, with the design opened up at the top and bottom it messes with the circulation. The cooler water falling from the top of the water line back down to the bottom of the tank will not displace the colder water at the bottom. It would be pulled in by the tuyere "the engine" over top of it instead. That's fascinating to me. Hard to accept. But kinda cool nonetheless. Oh well. I planned on building a 5 tuyere forge anyway. I'm just getting good practice I guess. The next ones should've take as long. So scrap the bottom "ramp", but go ahead with the top?

-

-

Um. I think I'm gonna read "Anatomy of a simple side blast forge" today. I just saw it.

-

Cool man! I posted a potentially ridiculous idea in "Solid Fuels" in the blacksmithing section.

-

I know. I know. I should've just kept it simple. But I have this itch sometimes to go the long way around to get to somewhere, instead of taking the direct route. That's just how I'm wired. I guess I just thought if opened up the bottom more to allow colder water in with less friction faster (is that even the correct terminology?), and opened up the top to allow the heated water in the nozzle to escape faster, than the natural thing that would take happen is a cooler tuyere. Hopefully it'll work. This would be a total failure. Why would the water do that? Why would the tuyere not have access to the cooler water? Heck. I figured it would make it easier for the water to cycle. Instead of a pipe that only juts out of the bosh, it's now a a larger flayed square tube. Please forgive the crude drawing. So if it doesn't work....well... nothing ventured nothing gained I guess. The stainless steel one that I made first was confiscated by my little girl. It becoming a lawn ornament that she can play music on. I've got to stick the air supply tube in a rock for weight.

-

Yes Sir I do. I took my first blacksmith class there a few weeks ago. A bunch of great guys.

-

Well...I was going to weld it to a stainless steel water tank. But since my daughter confiscated it I now have a different one. It still needs to work done to it also. Like the 1st, I'm welding it to a water tank made of sheet metal. Still would like to cover the front with some refractory mortar to keep it lasting longer. Will it work? I guess I'll have see. I can't think of any reason why it wouldn't though. I still need to fill in that empty space on the side. I guess I did already.

-

I wanted to do something different. Not trying to reinvent the wheel. Just wanted to try something different. I've not tested it yet. I'd still like to figure out a way to put some refractory mortar on the front of it. I've never used refractory mortar so I don't know how sticky it is or what happens after it gets hot. Does it shrink, or crack? I have no idea how long I spent on this one. But when my little girl saw it she immediately took spoons to it and rung it like a bell. When it started maki g different pitch sounds she said "It's mine now Papa". I sighed. Said ok. And began making the next one that I'll put in the next post. It's just mild steel. This one is 316l.

-

Water I've got access to all the steel I could practically want. A Jabod forge would be fun to do with my kids. I know my 5 yr. old son would be stoked helping me put that together. But this first one will be steel.

-

I have a few pictures that I have of the 2 tuyere's I made and the steel platform I was planning on using for the forge. Where should I post them at?

-

Ha! There's day's I seem to live in a dunk tank. Take your best shot. But since your here. Since I've been reading through the Forging101 and Burners101 I've scrapped my whole idea for the forge I wanted to build. What I considered to be practical....well.... would not have received any gold stars around here. I'm a structural steel fabricator/welder subcontractor for Wright Patt AFB. The government typically has the mindset to spend lots of money on either the best materials available and over engineering everything. So it was was only natural for me to follow suit. I'm going to build the coke side blast forge first to get some experience in just the elementary skills of the heating and forging before I move into a gas forge build. I'm fully capable of building either. I'm just now aware that there's much more to fully understand before starting the gas forge. I can continue to learn and maybe build a small one first in that time.

-

Hey thanks Steve! When I get it done I'll be sure to show it to everyone. It's my 1st forge, so I anticipate some constructive criticism, which ofcourse I'm looking forward to.

-

Hey Frosty. Hot. Whew! We had a heat index of 100° today. You got a.c. up there? I'm building a solid and gas forge simultaneously. See I built a monster pedestal for my wife 3-4 years ago for the washer and dryer. It's, lol, easily a couple hundred pounds. Well it's sat outside for that long too. I never finished it. So I'm reclaiming it as the table for the "forges". I want to put a side blast coke forge next to a gas forge on the same table. It's dimensions are 30"x58". I've already made the tuyere. I want to make a second one. It's probably going to sound like a stupid idea. I've been wanting to ask everyone's opinion, but didn't want to get laughed off the stage.

.thumb.png.4cf44700c8fab138e746722a49482f44.png)