WoodFireMetal

-

Posts

39 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by WoodFireMetal

-

-

-

Is Kanka double horn? I like the style and the 2nd horn is useful to me.

I'm up for options of brand. The main thing is that it’s lightweight for easy travel for demos, and not easily dented like my stake anvil which currently provides my flat horn.

Edit——-I just looked at the Kanca 77lb and see it’s a double horn. Definitely a possibility.

Thanks!

-

The darker one is 510 euros, the lighter, 525. Not sure what it translates to in dollars. They’re overseas.

-

I’m in the market for a 60-75lb anvil for museum outreach demos and I’m eyes these 2. They look almost identical except for their numbers, and the side on which they are stamped. Anyone know what the difference is between them? The darker one has a nicer looking face, which is my preference of the 2. The other is covered in chisel marks. I was considering a pig anvil because I love the look of them, but the idea of having to custom make and bend all its hardy tools to fit the curved hardy hole doesn’t impress me at the moment. Maybe in the future when I have a better skill set.

Also, does this brand have hardened steel faces? Should I worry about easily denting it?

Thanks for the help

-

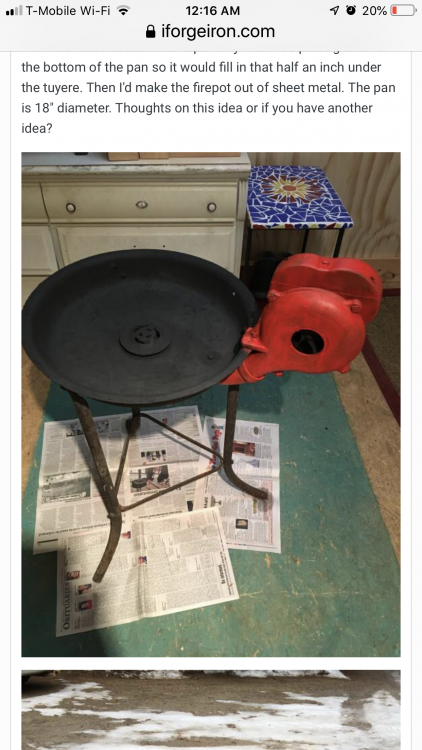

An 18” cast iron pan would probably be pretty heavy. Just a small skillet is pretty hefty. I accidentally stumbled upon a forum post while google searching and it turns out my “modernish” forge may not be so modern. Someone else acquired the same style and called it vintage (photo attached). And here I thought it was a homemade job. Doesn’t help me find a pan replacement, but I’m going to chat with some farmers this weekend at the farmer’s market about the ag discs. There is one style that is a little deeper that may help keep the fire a little more contained than the completely flat surface of the original pan. It just uses up way too much fuel and I’m finding myself fighting with the fire to keep it up. Unless I perhaps cut the center out of the disc and drop a forged sheet metal bowl into it as a firepot. Any thoughts on thickness of sheet metal?

-

Daswulf, I actually have a brake rotor forge I built a few months ago. Brake rotor and piping in a big box of dirt on lawnmower wheels which is not as portable as I need for museum outreach events. Way too heavy.

My hope was to find a similarly sized and shaped pan like the forge already has. Little did I realize how difficult it would be. My original search was for oil pans, but apparently they’re nearly all plastic, with an occasional aluminum one. A wok showed up as an option in that search, then all the suggestions above. Finally measured the existing pan and it’s just a hair under 18” between the 3 legs.

The stainless cooking pan I showed above has a neat double curve shape that already looks like a firepot bowl, but it’s 22” wide, alas. Not sure the thin tube legs would stretch that far without permanent bend issues. It appears to be conduit type piping.

Long term, I’d love to have a more historically accurate forge for colonial era events, but from what I’ve seen, that’s a major build. Jymm Hoffman has one and its a beast!

-

Anvil, thank you for the offer. It’s definitely a possibility. The new ones are out of my budget right now. The forge I have has a tuyere that is currently bolted to the pan. It fits well for the crank blower that came with it. The intention was to cut a hole and bolt it to whatever the replacement ends up being.

Thomas- I’ll wait to cut the legs for the additional ease of travel until I know what the final height of pan and tuyere will be, but that is a great idea. I can probably lathe turn a wooden plug of some kind to fit in the holes of the legs to get it back to original height for use.

-

In consideration of making a 55 drum base, would the metal be sturdy enough to leave a T shaped “backsplash”, where the top T part comes together to create a flu? Or will that require thicker metal? Or bracing to keep it up?

-

I appreciate those who mentioned the ag disc blades, but in a quick search, I didn’t recognize any supplier name to have an actual store. They all seem to be online sources, which Thomas seems to think is a dumb resource.

The only ag related store I know of in my area is Tractor Supply. The biggest one they have is 22”. I don’t know the size of the pan I have, but it might work.

-

2 hours ago, ThomasPowers said:

Uhh; are you looking online for stuff and then complaining it's expensive? Online is one of the most expensive ways to get stuff---like going into Tiffany's looking for a wedding ring and then complaining that wedding rings are too expensive!

If I knew where to look, in person, I probably wouldn’t be trying to buy online, nor would I be asking for help. I don’t have machinist, mechanic, or farming background, sorry. Nor do I have building experience, short of putting together a few small wooden goat and chicken houses.

I’m a 37 year old female who is self/youtube-taught and has been putzing with blacksmithing alone a few times a month at a tiny museum for a couple of years.

By prohibitively expensive, I meant that the shipping for the wok I had found was more than the wok, itself. I’ve never used one, nor have I seen one in person. It just happened to be the only thing I found online that had the correct shape.

This is all completely new to me, so pardon me for being a bit clueless. I came here for help, not sarcasm and belittling.

-

I’m not necessarily “focused on using a wok”. Prior to posting my question, it was the only thing I found online that resembled the pan it currently has and they come in different diameters, upwards to 24”, maybe more. My initial idea was to replace the whole pan with a wok, if that turned out to be a suitable replacement. Weber grills seem to me to be much too deep. If I cut most of the height off, I’m liable to have too little width left to work with. I also considered buying some sheet steel and forging out a new pan, if it came to that. I would try and create an actual bowl for the fire pot area and grate, then a higher plateau area for coal storage, then a lip to contain it. Or maybe that’s wishful thinking, with my lack of experience/skill. My opinion upon acquiring the forge was that it was too pitted and rusted through in several places to try and keep patching. If I’m wrong in that opinion, then I’m open to other ideas on how to keep patching it. It does have some very thin areas that have broken through and crumbled, the whole center has already been patched at least once, which is also old and pitted.

Irondragon mentioned using clay around the grate...are we talking about digging the dirt out of the yard, or is there a special clay I should look for? Cat litter, maybe?

Pnut mentioned using a fire pit bowl and they seem to also be around the same diameter, so that’s got possibility.

I want to keep this forge light and portable and able to be rested on its side (which may negate the clay idea) for travel in my truck. If that means replacing the bowl every several years, then I can probably deal with that. Given the level of pitting in this bowl, I’d guess it’s had many years of service.

I’ve included photos of some items I’ve found. Woks seem prohibitively expensive with shipping, so that may be out.

The 2nd and 3rd photo are almost exactly how I described what I would hammer out if I ended up with the sheet steel option.

Again, I’m up for options. Clay may be out since it will be rested on its side for travel.

-

-

Once I have it in my possession (hopefully this weekend), I’ll send a photo update of it empty.

-

It comes with a tuyere pipe and a cap that has little slits to prevent the coal from falling through. The blower also comes with.

What I need is a replacement bowl/pan. It’s rusting through. The wok seems to be around the same size/shape. A Weber grill is way too deep. If I were to try and hammer one out from sheet steel, what thickness would work?

-

-

I’m buying a modern-ish portable forge soon, but the metal bowl is rusting out. I think it’s about 20” or so in diameter. The closest thing I’ve seen online to replace it is a cooking wok. Is that a suitable replacement, or is it feasible to buy maybe a slightly thicker sheet metal and hammer out a bowl-ish shape from it?

-

I went ahead and used a 80 grit flap disc on the anvil and lightly dressed the edges and face, to some extent. As much as I would love a perfectly flat top, I didn’t want to remove much metal. Got most of the blue paint off, but it’s still buried in the pits. I also took a grinding disc and got as much of the old weld off the shoulder and flattened it, as best I could. Is there anything further I can or should do? Is this enough of a stake to hold it tight in a stump? Should I pre-drill and chisel square a hole to make it less lightly to split open the stump?

-

I recently acquired a neat stump anvil, as well as a tiny one whose horn would probably fit a jewelry ring. The larger one was welded to a thick pipe and tractor hub and I’ve just sliced through the weld and discovered a lot less stake than I expected to. I wanted to strip the paint and drive it into a stump to be able to take it to outreach demo programs for the museums I belong to. Are the stake ends always this short? Or did I just screw myself over by breaking it off its existing base? It’s only 4” long, though very thick.

Also...is a sanding disc on an angle grinder ok to strip the paint? I tried a small wire wheel on my drill and it wasn’t as thorough as I’d hoped it would be. Tough paint job.

-

Touché, to the hammer and chisel comments

:-)

I’m a newbie, for those that don’t know yet. I haven’t had a need or project that requires cutting sheet metal yet, but I guess now is as good a time as any. The only chisels I own, so far, are small ones purchased from big box stores that I use to make veins in leaf keychains. I assume they are not intended for cold usage. I was given a coil spring as a gift. Would that be useful for making one?

I believe Black Bear Forge has a video or 2 on making them so I’ll look into that, unless there are better video references to watch?

What gauge sheet metal should I use as the dirt tray replacement? Is the big box store a reasonable place to buy some, or is it going to empty my wallet?

The jig saws I own are also your average DIY quality, so I don’t know if that’s suitable for metal cutting.

-

On August 4, 2019 at 10:27 AM, BIGGUNDOCTOR said:

I just chuck wood chunks on the forge and get going, I don't make charcoal first.

I would have thought wood would burn way too fast, but I do have a fair bit of it laying around.

I don’t forge regularly yet, so it could last awhile.

On August 4, 2019 at 10:47 AM, pnut said:Have you looked into feed corn as fuel?

I have not looked into feed corn. Is it relatively non-smokey?

-

2 hours ago, pnut said:

Can you cut a round hole In a piece of sheet metal? If so cut the hole a bit smaller than the rotor so the rim of the rotor keeps it from slipping through the sheet metal. You could drill pilot holes around the edge of the sheet metal to secure it to the box.

Pnut

What would I cut it with? I have a hack saw, but it wouldn’t turn a round shape. I have a dremel with those EZ change-out cut-off discs.

-

I’m curious about this making of charcoal and I just watched a quick video of how a guy makes it. He fills a 30gallon metal trash can with his wood, tips it sideways and inserts it into a 55gallon drum, then tips both upright so the to-be charcoal wood is hidden inside the upside down 30gal. He then fills the leftover area inside the 55gal with more wood to create his fire. There are holes around the bottom edge of the 55gal drum, but none in the 30, that I can tell, except for the actual can’s opening, facing down. He lights the wood and lets it go for 3-4 hours.

I have trash cans and a 55gal drum. Is this a method that can work well enough? It seems like a waste of a lot of material to make material, but I guess that’s just how charcoal is made?

-

I mostly like my dirtbox/brake rotor hybrid forge-on-wheels I recently built, but it’s a bear to try and lift it alone into my truck to take to occasional demonstrations. I’d like to lighten it up some and wondered if there is a plywood or drywall like sheeting that would be resistant to the heat coming from the rim of the brake rotor, any loose coke floating around. FYI, I don’t know welding yet, so that option is out.

I’d like to remove the dirt, use a few firebricks to hold the rotor in place off the box’s wood floor, and have just enough bricks under the sheeting to keep it stable with coal/coke on top of it, flush with the rim of the rotor.

-

1 hour ago, pnut said:

I use a small metal barrel and make my own. I use yard waste, downed trees from behind where I live, pallets from the four wheeler dealership up the road and construction waste. It only costs a little time. I only spend money on store bought lump charcoal when I get lazy,run out of wood,or it's been raining. The charcoal I make is better than the royal oak from the store but every once in a while I have to buy it anyway.

Pnut

How do you make charcoal? Is there a good source online to learn? I made charcloth when I was a kid, for reenacting, but I assume charcoal is made differently. We have a good bit of downed wood. Splitting will be difficult, though, as I am rather petite.

Forging grooming clipper blades?

in Problem Solving

Posted

Now that you mentioned it, they do look like Pac-Man ghosts!

I would definitely cut off the teeth and use just the solid part. I don’t know about stainless because it doesn’t take much for them to rust.

I did email one company asking the type of steel and they said it was “proprietary”. One ad did mention the Andis blades being “chrome-coated carburized steel”.

not sure if the Wahl blades are coated. They seem more naturally colored.

Not with broken teeth. They’re unsafe to use against skin. The small blade on the bottom is replaceable, but if the large half gets a broken tooth, it becomes useless.