RocketScientist

Members-

Posts

7 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by RocketScientist

-

So I'm back again. As you may recall, my last Craigslist anvil find was a disappointment. The anvil was a little more sway-backed than I liked and had only 40% or so rebound... not worth the asking price. This one JUST popped up locally (could be there in 15 mins) and is asking $95. I'm assuming it was a railroad or similar-type track in a former life, but it seems to have been formed into an anvil shape some time ago, with hardy and pritchell holes, nice flat top face with sharp-ish corners, a little mini-table, and a decently-shaped horn. Current seller states he thinks hardy hole is 3/8", and will have to weigh the anvil later today to tell me weight. He purchased it in the condition it is now, and never got around to using it like he thought. I know in general track anvils aren't ideal, and the usual recommendation is to mount/use them installed long-wise, using the cut end as the work face (to get more mass under the face). So I'm sure this isn't what a pro would pick. But I'm brand new to this, and this is very local, and seems like a very reasonable price (depending on what it weighs out at). Just trying to get a feel for HOW non-ideal this setup would be, and if its "worth" the $95. Now I know cost/worth is subjective, but is this the sort of thing where I'll be able to do some simple work and start learning the basics, and figure out if this is a hobby I want to sink some money into and get a "real" anvil? Or is this something where i'll just end up fighting the crappy anvil, and it will make learning harder, and not be very useable? Any advice is appreciated!

-

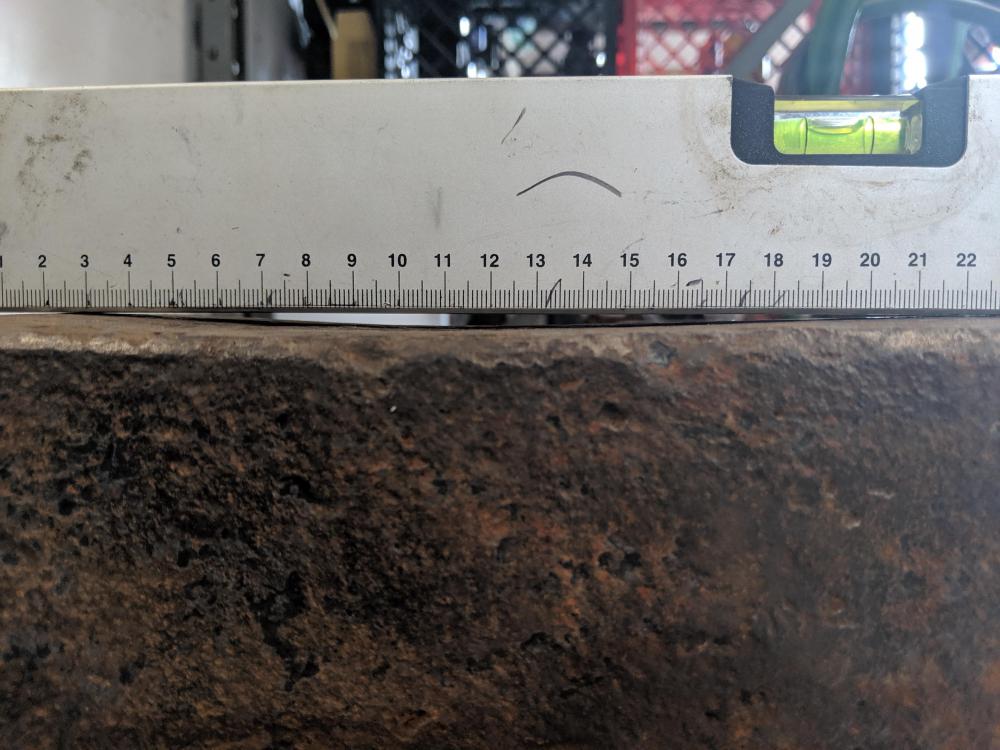

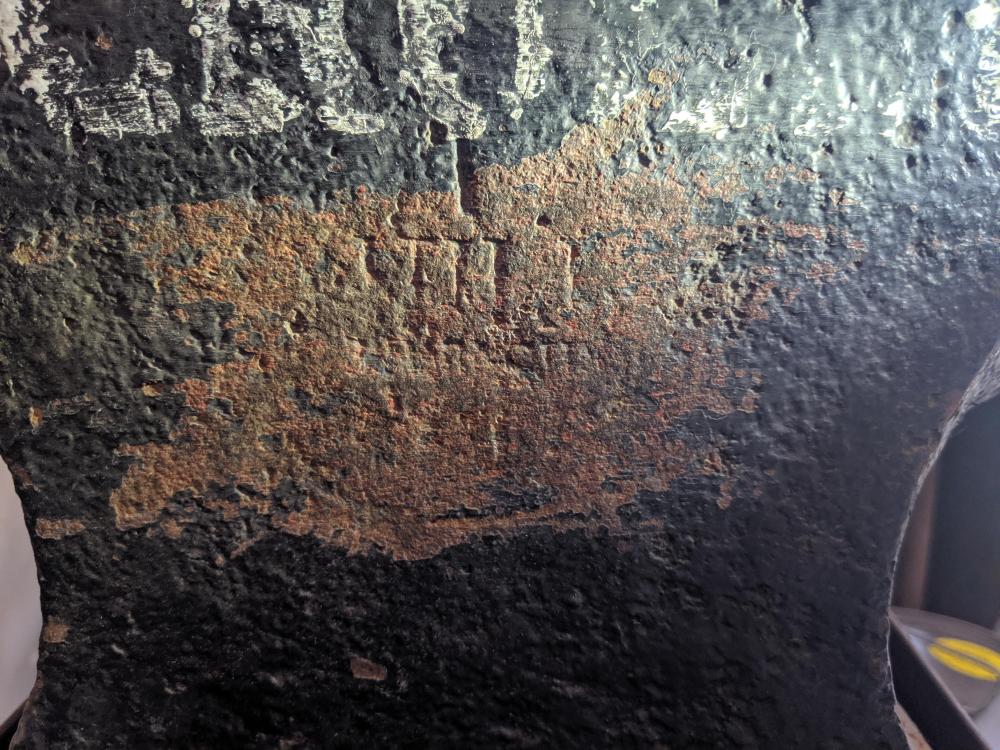

So i got a chance to take a look at things after work today. It's left me a little unsure so I would really appreciate your thoughts on whether it makes sense to buy it: - Reason for selling: guy is basically "flipping" the setup. He has a few local scrap yards that let him know if they come across an anvil, and when they do and it seems useable he builds a forge for it, and sells them as a set. He runs a small auto custom/repair shop where I met him, he was kinda busy working so wasn't super talkative. Didn;t have any more details on the anvil (backstory, etc). -Rebound: using a 1" steel bearing, dropped from 10", it would rebound only 3-4". I achieved a pretty consistent result at various points across the working face. Results were maybe a little worse in the center where the top is most dinged up and the sway is the worst. -Ring: It's been probably 20 years since i last struck an anvil, and that was very limited exposure, so I really have no reference point for whats "good". It wasn't totally dead/muffled, there was a high pitched impact ringing, but it didn't sustain for very long (not like hitting a bell or something), and in most places sounded... harsh? Had almost a grating, off-key quality to it (fairly subtle but noticeable). I work doing vibration and shock testing in the space/defense world, so i have some familiarity with metal fixtures and assemblies ringing from impact, and the closest thing it reminded me of was if there was a bolted joint that wasn't quite torqued fully or a there was a cracked weld or something and you get this almost chattering/grating/unpleasant sound instead of a nice clean single-tone DINNNNNNNNNNNG. It wasn't blatant, and maybe I'm just being paranoid, since I don't have a good reference point. But it didn't seem like the nice lean clear noise I had expected. Was not present or at least dramatically reduced when I'd tap the sides of the horn/heel. In those locations it would be a more clear/clean ring, ditto for when tapping most of the corners and edges of the work face. -Sway: Was a little worse than I'd expected, the ole' eye-crometer puts it at about 1/8" at the worst, mostly restricted to the center of the work space. See pics -Condition: work face was a little more dinged up than I'd thought, but not TERRIBLE and there seem to be enough other smooth flat areas for if/when I really need that.The edges are in worse shape than I thought and with a lot fewer sharp areas, for whatever thats worth -Markings, some faint remains of recessed lettering, and what I'm guessing is a weight stamping (1-0-19? ie 1 hundredweight, 19 lbs or 131 pounds?). Please take a look at the attached pictures and share ANY thoughts or information you find appropriate. The rebound test really has me a little cautious. The ring also has my gut going "this doesn't sound quite right", but with no real good reference points I'm hesitant to give that alone too much weight. In general it was in a little worse shape than I thought. Any advice on whether this sounds like something I should walk away from, or if it sounds like a usable (if not ideal anvil) if I can get him to come off his price is appreciated. I have additional pics I didn't post, if you want to see another angle or a closeup I may have more to share.

-

Wow, thanks for all the replies guys. To address some questions/comments from several people: - I havent spoken with the seller directly yet (ie via phone or in person), he's slow to respond to e-mails and such and I don't want to keep pestering him (seems like an older guy) so I've been waiting until I have a few things to ask, then reaching out to him. Hoping to run up and see the setup in-person today or in next few days (its an hour or so drive and my work schedule has been crazy this week). Not sure why he's selling though I will be sure to ask. - The forge he describes as: and he provided the attached photo. Again, I haven't seen it in person or watch it run. - Seems general consensus on the anvil stand is its not particularly great and maybe even more hassle than it's worth. Thanks, I will keep that in mind. I have a public brush-site nearby that usually has a wide selection of large logs/stumps, so plan has been to mount whatever anviI get to one of those.

-

Thanks for the feedback! Some points you raised: - I haven't seen it in person yet, so cannot assess rebound yet. Will be checking that out with a bearing if/when I do. - I AM in the market for a forge as well, so his would save me building one or buying one outright. His is home built, but based on his description/pictures looks like a reasonable job (again, haven't seen it run in person so can't say for sure but best I can tell). - Good point regarding height of stand. -I'm located in Florida USA

-

Have a saved search for anvils in my area, this one popped up recently. Seller states: Obviously its not in pristine shape, but I'm VERY new to this and don't really have a good eye for something thats well-used and broken in, but still could be used effectively to do work vs something that was trash to begin with, or is beat to hell and would be more trouble than its worth. Basically, I'm hoping y'all can give me some thoughts on if this looks like it could be a useable anvil (assuming no problematic cracks, good rebound etc) or not. And if so, any thoughts on reasonable price? or really anything else. Oh, and seller is asking $600 for anvil/stand, plus a 2-burner regulated propane forge/stand/bottle. Not sure how firm he is, or if willing to separate. I'm new to this forum, so if I'm breaking rules, or this belongs in a different sub-forum or this is the 10,000th post like this and there is a sticky/FAQ that answers all my questions, my apologies and please direct me to my mistake (I checked for all these things as best I could, but you know how it is on a new forum).