Dwithrow84

-

Posts

15 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Dwithrow84

-

-

-

-

I've got a few coil springs and I can get leaf springs from the shop but i'd have to cut them, heat and flatten them. We've got a few steel places here in town but they only sell mild steel. we have a TSC too. I thought buying the cheap hot rolled steel would be a low cost way to practice without having to fire up the forge and waste the gas. I mean I don't mind firing up the forge I enjoy it but if I'm just practicing stock removal and bevels and not producing finished products i'd rather not waste the fuel.

-

do you guys think it would be okay to use a low carbon steel to practice on. For blanks if I only plan to practice grinding and stock removal I thought maybe I could use like rolled steel from lowes to keep the cost low since I will most likely jack it up.

-

Pnut I dont know what a franklins cross is but ill look it up

-

1 hour ago, Frosty said:

"Adult skin thickness?!

" lol yeah something like that.

" lol yeah something like that.

15 years Active Duty military, Vehicle mechanic. We talk pretty straight forward to each other lol

-

So I finally made something. I have had no training and the only thing I know about forging is learned from videos and a couple of books on blacksmithing. I dont think its complete garbage and know I have lots of room for improvements needs more refinement and has a horible grind. I just wanted to make something. Anyways here it is try not to laugh to hard.

-

Frosty,

I dont get offended easy...lol. it was offered to me by the guy i bought my grinder from for $300 and i know they sell for around $2k so i thought man even if i dont need it i could probably resell it. I agree with you though i am not at the level to be buying large equipment like this yet. Infact i just forged my first knife on Monday, it was pretty rough but thats not gonna slow me down i know its a learning process. The nearest place to take classes is about 5 hours away from where i live but i met a couple of bladesmiths that are giving me some pointers in the mean time. I am always open to criticism, how else can i grow and learn. Thanks

-

Thanks Irondragon Forge & Clay for the heads up. I just updated my profile. I'm also a little worried about having to re-weld the tools, I only have a flux-core welder but usually get pretty good welds with it. I figure I could give it a try if it works, it works but can't hurt to try. I forged my first knife just this week and I've been so anxious to just get back into the forge.

-

I think ill keep it and give it a go. Thanks Thomas, hope it works out well

-

So I got the Bader BIII being held for me. I'll pick it up soon. $200 I felt was a steel but didn't know anything about the grinder. thanks for the push guys hope it works out.

-

Thanks Steve

-

So I'm new to blacksmithing/blade smithing and had a question. What do people use a kiln for. I understand quenching a knife and such but i'm unsure what to do with a kiln. I found a Evenheat kiln at a very low discount and wanted to know if I need it and what to use it for, how to use it.

-

So I was wondering if anyone on here uses or has used a Bader BIII 1.5hp Belt grinder. I saw one used and thought I'd pick it up but wanted to get some peoples opinions on the grinder.

-

I know this is an old post. I am in the same boat, just starting out. I have a plate from rail road tracks. the plate that the track sits on. its already got the square holes in it. what I was planning on doing was put spikes through three holes to hold it down and then cut off the top of a rail road spike and use it to stick in the hole then I could weld what ever type of hardy tool I needed on top of old spikes. Not necessarily use the spike as the tool but the square to put in the hole. is there any concern with doing this or do you guys think this would work out.

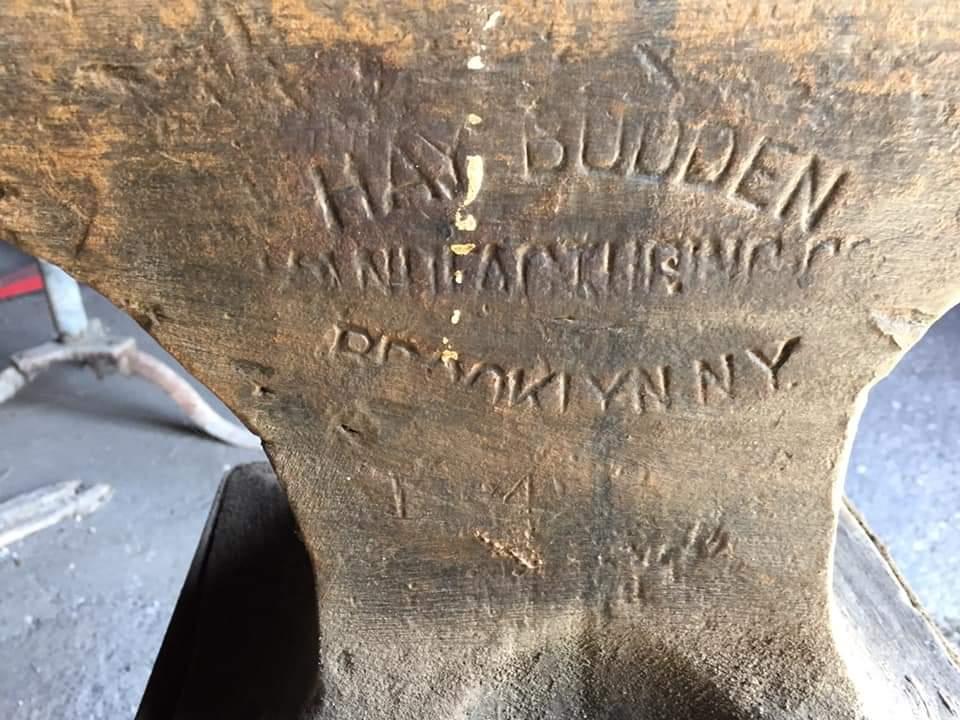

Help Hay-Budden

in Anvils, Swage Blocks, and Mandrels

Posted

So this Hay-Budden anvil just popped up on Facebook today and was wondering if they make good anvils and what you guys thought would be a good offer. The post says "These are listed on the internet for $1000 to $3000. I’m looking for the best offer. I don’t want to move this heavy beast."

I am currently using an old piece of rail road track so this would be a nice up grade but not necessarily a must right now either since im just starting out. Let me know what you guys think