-

Posts

131 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by CheechWizard

-

Picked this old belt driven band saw up for 25 bucks down at habitat the other day. Wheels seem to be about 12 3/8in. Anyone have experience with these old saws?

-

used rasps be more common in my parts

-

i don think ill be putting my parker majestic spindle assembly any where near the forge, or running it anywhere near 15,000 rpm's for that matter.

-

my very nice neighbor offered me this little band saw he picked up for practically nothing at an auction. of course i obliged. I also hit up the owner of the suspension shop down the way about his scrap pile, told him i could make forge him something neat in exchange for a few pounds, he didnt seem to think twice about letting me have at it, made 3 trips on my skateboard and when i came back the last time he had thrown pair of king pins to my pile. anyone have any experience forging these? the spindle is also a hand down from the neighbor, what a guy.

-

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

wow you guys have been killing it lately, nice work! i havnt done much forging as the heat lately has been unbearable, besides an hour or two in the evening when i have a chance but i did throw together i little wood lathe and fabbed up a little guillotine tool. i was given a spindle and housing for what i believe was for a Parker Majestic surface grinder that im in the process of rebuilding. I plan on using it instead this oversized motor lol the dies are made from mild steel bar with RR anchor welded to the business end . -

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

-

wd40 was originally designed to protect the Atlas Missile from rust and corrosion, fun fact.

-

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

speaking of welding that old monkey ward buzz box has been pretty fun. im horrible at using 6011 but luckily my buddy gave me a bunch of 7018 and this 7014 that works so well you just give it a tappity tap and the slag shell pops off revealing a crispy stack of uncirculated dimes. im getting pretty ambitious with this lathe build. hopefully im not in over my head. -

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

jaeger, find some old hinges and some bolts until the welder man shows up. And skiing/snowboarding can be a deceptively dangerous sport, especially for your casual riders who only make it up once or twice a year if that. it's easy to forget you're gliding as fast as a car on the highway but on sometimes you're on bullet proof ice or just a little dust on crust. not to mention on deep days you got the padding but you still have trees that will most definately win in a wrestingly match against you, even the small ones, take it from me i broke 2 ribs hitting a treet and i was barely moving, my buddy whos an airborne ranger was quite amused at the face i was making he just had to get a picture of me in agonizing pain with the wind knocked out of me. bit of a sick puppy that one. -

this knife is gorgeous, im inspired to finish a wrought san mai with a similar grind after seeing this, it just needs a bolster and a hand but ive started two handles already that dont feel right, just too much going on. this is a nice reminder that adding more curves and facets wont always make a nice knife. i'm not gonna just copy your handle dont worry but again thank you for sharing its so pretty but also too nice not to use the heck out of.

-

thanks guys

-

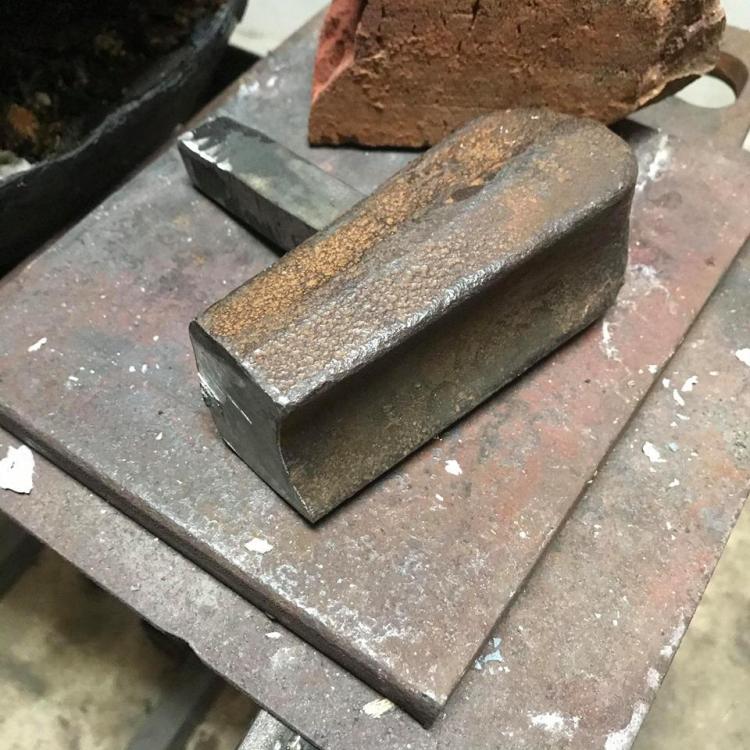

speaking of stones i found this 2 sided stone for a couple bucks at a second hand store, looks to me they're arkansas perhaps?? what you guys think? they something like 400 and 800 grit which is perfect for refining a secondary bevel me thinks. you guys have any advice on maintenance for these things? ive never owned a real stone before (at least it looks real to me but im far from an expert obviously)

-

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

I've been doing all blacksmith related stuff at night on my days off because its been so hot and humid i barely want to move during the day. unfortunately i cant really hammer and try to do all the cutting i need to do before 9ish. I've developed a good relationship with the neighbors no need to spoil it although its so hard to resist the urge sometimes especially when you finish up a swage or top tool and want to test it. Today was the worst heat wise its been this summer so far, but its cooled down finally so i may go work on a spring fuller i shaped and normalized everything for last night. I used an oddly shaped piece of high carbon steel i found a the scrap yard, it was some kind of latch or coupling with one part that was clearly a hook that got bent so that the whole thing from one side looked like an elephants head lol. one section of it was already perfect shape and size for one side of the fuller and i straightened out the hook (which was a real pain) for the top. The spring is from a coil spring wouldnt you know. Here's a concave forming tool i did last night, not much had to be done accept put a pin between the 2 pieces and weld. i have no idea what that thing used to be but it is low carbon unfortunately so ill have to be careful not to deform it to much -

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

i drilled and riveted from the bottom on the anvil to the top of the stake with a small piece of round -

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

xxxx nice work everyone heres the first stake anvile ive tried, as nasty as the welds are i think they penetrated enough that it will work. made from an old estwing mason hammer -

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

i think we all know the actual truth about those professional blood siphoners frosty... lets just say if you were a vampire who was trying to assimilate within society wouldnt drawing blood for money make sense? you're able to afford your own place instead of crashing with all the other hobo vampires that still live in that bando crypt from the 1700's. While also having a selection of all types of uhmm lets call it koolaide. -

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

on 110v its rated for 16 amps, rooster. which would seem to be slightly underrated however its been working fine. think im gonna use it to power a little wood lathe ive been wanting to build. i scored this mount that has a pulley going to a 3/4" shaft which would make a really good headstock if i can get a chuck mounted for a reasonable price then the rest shouldnt be to hard to buid. perhaps just a simple track with some pillow blocks mounted to a plate for the tailstock and tool rest i can re-position and lock with some ease. i could do something like a screw with a back plate type deal and a tail stock with a center but a chuck would just be so much better speaking of requests from loved ones my lady asked if i had anything i could give to her dad (my future pops inlaw) and remembering that he showed interest in previous hatchets so i decided to bestow upon him that latest one i did. i really really liked throwing that one and i was happy i finally had a decent one i could keep for my self but staying in good graces with my girls parents is of high priority and i was able to get that one done in a nights work, with a morning to do the handle and finishing it wasn't a very hard decision at all. (for me thats pretty fast but i know i can get better and start doing better) i made my first stake anvil last night and i may top of a large piece of rail road track with some plate and use it for a striking anvil tonight. ill post pics later -

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

yeah thomas the wording doesnt make sense on alot of that post lol. the bit of an axe just refers to its cutting edge right? anyway thats the first one ive done out one piece of steel versus the last 2 i did with punched eyes and forge welded leaf spring bits, and the ones before that were wrapped eye. sorry for the confusion. -

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

made a simple throwing hawk without a forge welded bit so its not a hardenable steel. just wanted something i could toss around that wouldnt take alot of time to make. i have a neighbor 2 houses down that has proven to be very generous and helpful in my endeavors have turned me a tracking wheel for my belt grinder not long ago and going on to consistantly give me assets to the shop as well as passing on wisdom as he made his living doing all the mechanical related stuff for our local power company. so we got to talking about how my little harbor freight fluxcore welder has failed on alot of the tooling ive tried to fab so he hooks me up with his old monkey ward buzz box. cant beat free and if that wasnt chill enough he threw in a auto darkening face shield and a bunch of different rods, even hand trucked it down the street for me. heck of a nice guy. how do you repay a guy who has everything? im working on it. so here's some stuff from the week, the chisel has been a work in progress that i do a bit on here and there inbetween projects, scored the motor from habitat, kinda over paid for it (single phase, 1 hp, 110v, AC for 45$) but i like the features and have some ideas for it (btw does anyone know if that switch set up is fine for a motor like this?) -

ive found 5160 to be one of the easier steels to harden, and it gets quite hard, i sometimes temper it a couple times, like they said throw its right in the oven and get it to light straw, then do some differential tempering as needed. as far as a kitchen blade goes, the edge geometry is so narrow if you were to not realize the hardness you would chip that bad boy the moment it makes contact with something other then a tomato, probably even just by sharpening it

-

idk about the v dub fan shroud, i dont think they used little unvirsal motors on them

-

awww and i spent some time editing the typos and grammatical errors and it did not save

-

to be surprise the thing screech bit and after a bit more wd40 dowing it started moving alot of hvare. andone have experience with these? im thinking its either from a little hvfac furnace or automotive related. btw that lever closes to 2 small outlets

-

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

thanks JLP! i think i may start with bigger stock so i have material to draw out some cheeks, but for learning it was perfect as it was very hard to slit n drift the eye -

What did you do in the shop today?

CheechWizard replied to Mark Ling's topic in Blacksmithing, General Discussion

mild steel with a leaf spring bit, got some minor delam during the quench unfortunately. handles white oak with boiled linsead oil finish, the grain isnt exactly vertical but it will do. it has a hand sanded finish with gun blue patina.