-

Posts

8 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Kagé the Tinkerer

-

-

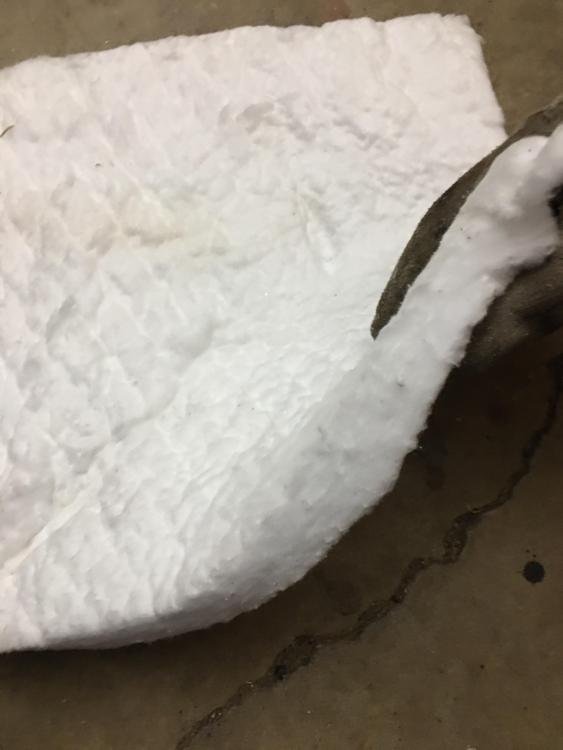

Hey y’all! I was given some ceramic insulation(the blanket kind), and was wondering how to determine what temperatures it’s rated for? It’s 1” thick and white, if that helps(idk if different temps are different colors).

TIA!

- Kagé

Edit: Also, I’m hoping to use it to line a gas forge and I’ve heard you need to rigidize the blanket, then coat with refractory? Any recommendations on that would be super helpful too.

-

On 5/14/2019 at 12:31 PM, Kozzy said:

Do a search of this site for information about claying and mixtures to use. Refractory and other cementitious products are not the best options. It's one of those areas where simple is better.

I have some green sand mixed up that I was planning to use to line a new melter. Would that be a better option for lining the forge, and use the refractory in the bucket instead?

-

10 hours ago, Kozzy said:

Your photos imply that part isn't there (or my glasses need cleaning).

The handle may be a bit shorter than I've seen....

With a cast iron pan like that it will definitely be necessary to clay that forge before use to prevent cracking.

- Your glasses are fine. Lol. I’d seen those in pics of similar forges, and was planning to rig one up for mine. What I’ve got now is already denting my new handle.

- It’s the same length and hole positions as the one I got it with, but that could’ve been a replacement handle already, and been shorter.

- Thanks for the tip! I just got some refractory in a couple days ago. I’ll slather some on there.

Steve - the fan still had one blade attached, and it’s cast iron, almost the same thickness as the stock I used to make the new blades. Ideally, in the near future, I can cast an entirely new fan, but we’ll see how that goes.

-

I used bar and chain oil. Got everything turning, but my homemade blades were wonky, and catching on the edge of the blower housing. Got ‘em ground down and straightened, and they’re setting for the next 24hr to let the adhesive cure. Barring any other oversights on my part, I think I’m good!

Fingers crossed, I should be up n running tomorrow night! Tuesday at the latest.

- Kagé

-

After much searching around, I realized I never lubed anything after I put it back together.

Rookie mistake....

Rookie mistake....

Now the handle, 1/4 gear, and drive wheel turn, but the belt just slides over the small wheel with the fan. *sigh*

-

It does. 1/4 wheel ratchets the drive wheel.

And thx for the welcome. I’m excited to get started!

-

Hey all!

I bought this old rust bucket coal forge. I believe the term I’ve seen used is “rivet forge”. Zero make/model marks, that I can find. Tore the whole thing apart, replaced the pump handle, drive belt, and all the nuts n bolts. Three of the blades were busted off the blower fan, so I fabbed up some new ones, and attached them to the existing fan. Sprayed all the parts with a high temp, rust resistant paint, and reassembled the whole thing, only to have it NOT PUMP, SPIN, OR BLOW AIR!!!!

Please help. The belt is nice n tight, the handle has room to maneuver, and the new fan blades fit inside the blower housing....what’ve I done wrong??

Also, there are extra holes in the pan. Any idea what those would be for?

TIA,

- Kagé

How do I determine the heat rating of inswool

in Insulation and Refractories

Posted

Is there any way to visually tell whether I was given the 6# or the 8#?

I guess, more importantly - does it matter, since I’m hopefully going to do 2 layers, with rigidizer and refractory?