Dasher

Members-

Posts

70 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Perth Western Australia

-

Interests

General diy stuff, sports, m/ cycles, not much riding nowadays, but working on friends and family bikes. I make and play [badly] cigar box guitars

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

What works best to free rusted parts

Dasher replied to Roy56's topic in Gunsmithing, Muskets, Flintlocks etc

Update, I've freed 1, still 1 to go, no hurry, it will come eventually I'm sure. -

Metal bandsaw vs chop saw - which to choose ?

Dasher replied to BartW's topic in Saws, bandsaws, hack saws, etc

I'd go for the cold saw every time, but I've only had little use of a metal bandsaw, so others with more bandsaw exp may disagree. I suspect your relatively cheap bandsaw will have to work hard at the risk of maintainence and renewal of guide bearings etc. There isn't a lot of inherent risk in a cold saw, but a sound clamping system is a no brainer, because while it may be low speed, it has torque to burn. -

What works best to free rusted parts

Dasher replied to Roy56's topic in Gunsmithing, Muskets, Flintlocks etc

Thanks big gun, I,m going to hold off putting them in the oven for now while I try a few other things, Irondragon's suggestion sounds logical, so that is next. -

What works best to free rusted parts

Dasher replied to Roy56's topic in Gunsmithing, Muskets, Flintlocks etc

Not rust per se, but related, I,ve just today started to re new my old motorcycle, hasn,t run since the late 80,s, [ family , work, yada yada], apon pullng the carburettors, I discovered that the slides had seized in the throttle bodies, as they were only a 100 or so hrs used since the bodies were last sleeved, I,d like to save them. They are currently soaking in a wd 40 mix, but I was wondering if someone might have had this issue before. As the bodies are made of pot metal, any introduction of heat must be very judicious, any and all advice appreciated. -

I agree with pnut, most likely mild steal, pressed metal or aluminium, come along handles a generally short of length , with all the work being done by the geared mechanical advantage, I've seen them bent, broken and abused and nothing leads me to think they are made of anything of note. As a side note, whether by design or coincidence, comalongs are hard to break or damage when used correctly and to it's rating, but you add a "cheater bar" to the handle for a bit of extra grunt, and you will kill it very quickly.

-

Well picker77 I applied for a job there in the early 80,s, doing maintainence on the towers, I missed out, in hindsight, luckily, I, ve already had 1 knee and 1 hip replaced, and another hip being done soon. I think had I been climbing 1000' towers all these years Í' d be on my 2nd or 3rd set of hips and knees by now.

-

Thanks picker77, yes I think I will need to sort some time of platten arrangement eventually . BTW that communications facility you mention "near Perth" is almost 1/2 way up the state, over 700 miles from Perth.

-

Thanks picker77, I've got it running and tracking well atm, haven't made a lot of dust due to other things needing doing, but I' ll run it as is for a while and keep up the maintenance like you noted, if it lasts 1/2 of 13 years they can put it on my coffin.

-

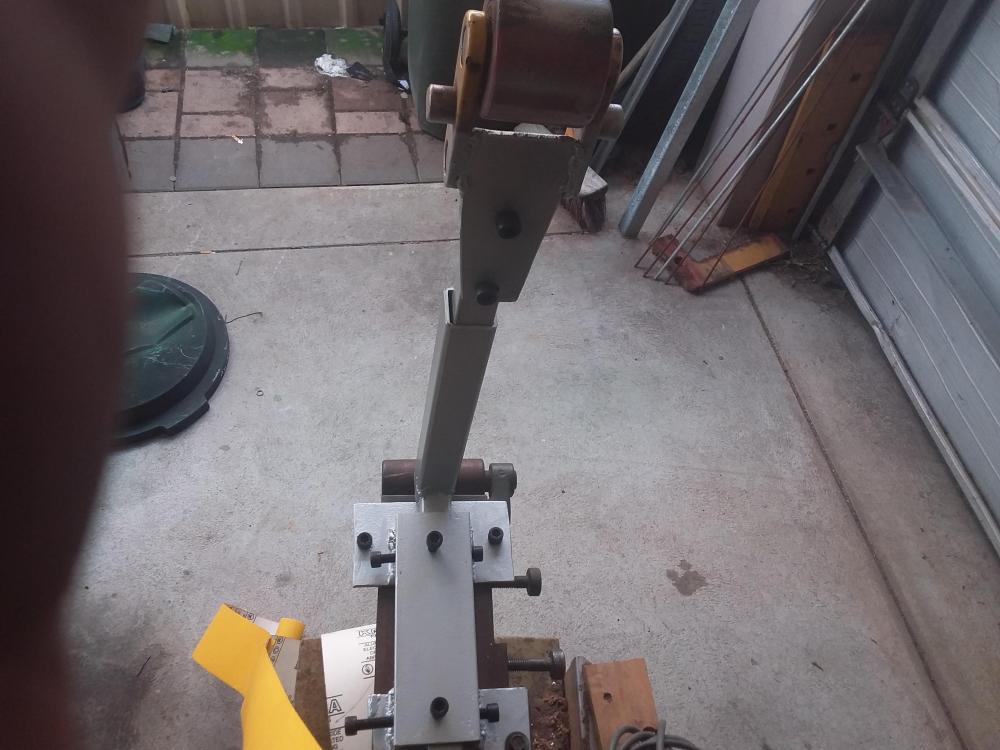

Update, and more questions; The belts finally arrived and I tried them out, everything runs pretty well and true, the only issue being a bit of belt "flutter" [for want of a better word] on the hypotenuse leg of the triangle, where the belt is first "pushed" from the drive pulley, given that ATM I have only tried ultra cheap ebay belts, am I over worrying about it, or do i need to add a 4th tension wheel? The working leg of the belt runs very smoothly and the vertical support is spring loaded, and I have tensioned it to what I guess and feel is about right, I'm hesitant to tighten any more without some advice from people who have been through a similar trial. Thanks for taking the time to read, and all advice appreciated.

-

Are there any structural engineers on here?

Dasher replied to BIGGUNDOCTOR's topic in Everything Else

Interesting idea BGD, sort of a mud brick/ adobe method, the structural ability would be quite high given the large base area, but a couple of problems you might face are; while the filling is dry the bags will settle and "nest" together very well and become very stable, but full sealing of the joints, especially vertically will take a bit of thought. The other thing that comes to mind is are the bags uv resistant? Or can they be made uv and weather resistant? If not , depending on the material the sacks are made of, they will deteriorate pretty quickly and your dry mix will probably leak out, so you may need to add a binding agent and water to the mix, then that becomes a procedure issue, to either fill and cure the blocks in a uniform shape prior to installing, or filling and installing immediately and letting the bags nest and conform to each other as they cure. From there, the next issue would be how long to let the structure settle before shot creting, and you will need expert geo advice for that and if you have extreme weather/ temp changes, it could be a party stopper. This is by no means authoritative advice, just my thoughts from many years in construction, I hope you manage to sort it out as the idea itself is pretty sound, but you do need to get it right. -

Thanks Pnut, I'm just trying to make do with stuff I have laying around, the existing sander works ok, but being horizontal and waist height, it is hard to do detail work or sharpening without being in a bad posture, and these old bones complain when I do, so I figured the vertical belt section will take care of that, and it's only 5 minutes and 4 bolts and it can be set up as before as a bench sander, if it works ok, I'll keep an eye out for an enclosed motor.

-

I am currently in the process of upgrading my old 4" x 48" bench sander to take 72" x 2" belts, and while waiting for some cheap sanding belts for setting up with to arrive, I thought I would throw it out for anyone to comment , good or bad , whether my system is likely to be ok or not, in the pics attached, I have stapled some 4"" sandpaper I had to make a 72" belt to get the geometry close to what I need. My main questions are ; The vertical post is spring loaded internally, allowing a bit of give vertically, will this be ok? The existing sander has a tension/ tracker head pulley, do I also need an adjustable top pulley? The top pulley is adjustable now, by about 7 degs either side of centre along the line of belt, and 2 or 3 degs either side of centre horizontally at the head, as these are not idiot proof safety wise, I'm hoping they will be set and forget, once I have a belt running true, and any tracking adjustments for change of belt etc, can be handled via the existing tracking controller of the head pulley which doesn,t need hands or clothing near the moving belt. Next, with the reduced contact on the drive pulley, am I likely to get belt slip, or should I rubber line the pulley now?, Lastly, as the motor is not enclosed/ sealed, would a light metal enclosure with a strong magnet attached reduce the entry of airborne filings, my Idea is to keep the enclosure far enough away for the magnet to have no effect on the motor field. Almost forgot, does the top pulley need to be radiused, or should flat be ok? Thanks for reading all this, and comments, yay or nay appreciated.

-

Man, I had an EK when I was younger, all of them having the same tail lights is what put me into guessing mode.

-

Looks great Ausfire, even better in the FC/ FE?

-

Need help reversing a motor (if possible)

Dasher replied to JHCC's topic in Machinery General Discussions

As others have said, many AC single ph motors are not reversible, have you considered turning the motor around and driving the saw via a lay shaft? It will probably cost a few bucks for the added pulleys / bearings etc, but it is an option.