Whiskeymike

-

Posts

75 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Whiskeymike

-

-

Much appreciated folks.

-

Perhaps this is a modern invention with no roots to the past. I found this when searching -

But I don't see any ratchet. It seems to be a pin in his hand that just inserts to stop the wheel. it also looks like something made from previous parts, but not in the pioneer period.

I assumed there was similar mechanisms used in fireplaces, but perhaps they were all trammel hooks or a form of it.

-

I'm looking to make a gaucho/wagon wheel grill where you raise/lower the grill from the fire and wondering if anyone has seen blacksmithing designs for the ratcheting portion. It would be similar to these parts, but I'd like to stay fairly authentic.

So if someone know of a 1800's/early 1900's reference material to such a thing, I'd appreciate a pointer.

-

-

Thanks for the suggestions. The full tang with scales is a good idea for hand tools. Although the items I have in mind are about a 3-4 foot reach. In some cases, it’s to give reach in 4x4 raised boxes, without a lot of repositioning the chair. In other cases, it’s to reach the ground from the chair. In all cases, the head needs to be much lighter and smaller to reduce fatigue. Handle will be thinner and lighter as well.

the search term suggested helped a lot. It provided some good examples to study. I’ll keep looking. One of them had a 4-5” tang, and the handle was split with a notch that the tang slid into and was bolted with two bolts. Although it seems like notching the handle might weaken it, but perhaps the tang deals with the leverage applied.

Found this great walkthrough on making a ferrule. http://taigoostudio.blogspot.com/2012/06/how-to-forging-fabricating-and-fitting.html

maybe some tweaks would make it work for what I’m doing.

-

I'm looking to make some garden tools for someone in a wheel chair. So they will be downsized in the head, shorter handle, but similar normal width. I'm trying to find information on the best practical processes for making the tang and ferule(I think that is what it's called, the cone that holds the tang to wooden handle). This doesn't have to be authentic processes from 1875, but focused on solid construction, will hold up well.

Any thoughts?

One thought I have is steel pipe/tube smaller in diameter than handle and then flare out the end on the horn/ a cone. Then make tool head with tang/wedge end, weld into end of ferule, then bolt to handle?

-

-

Great, thanks for the info. I had searched the forums and came up blank.

-

I'm wondering if anyone has tried putting a screen in a NA burner after the gas introduction to force mixing of the propane and air. Much like a gas lens on a tig torch flows the argon.

Mike

-

John B, that looks very nice. I'm jealous of your patience.

I'm brand new to black smithing, but have been doing metal work for a while. My wife is mostly Irish and we both enjoy the patterns and art, so I like to include those influences to keep on her good side. This is the starting layout for a design I'm working on for 3 Trellis that will go against pillars on the porch to support rose vines. I plan to make it from 16ga steel, and my hope is to make some celtic knots (or at least the weave pattern) from 1/4 - 3/16" steel rod and incorporate it into the design for the border around the sheet, or through the large knots that are cut out. Triquetras are another element that I'd like to work in.

I received the books and they are good recommendations. It's definitely going to require some trial an error. A fair amount of it is very fine detail that I'll have to work towards over years, but it definitely helps wrap my mind around construction.

-

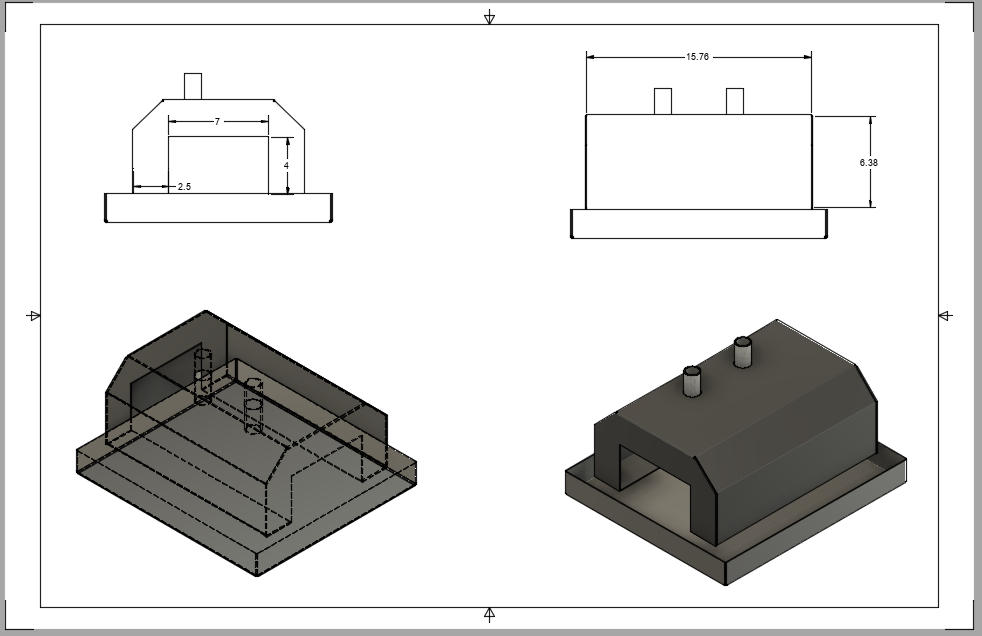

Working on designing my forge skin. I'm planning a 4x7x12 internal work area. Inside will be lined with 2 inches of Kaowool, Rigidizer, 1/4" Kasto-like 30, and Plistix.

Design is a small version of Essential Craftsman's forge where the top body separates from a floor which I think will make maintenance/modifications easier as well as the cool ability to temporarily in a pinch, raise it up with blocks to be able to heat something odd shape.

Anything I've overlooked? Is there anything I should be doing to hold down the kaowool? Might be something I could design into the form. I'll be CNC plasma cutting the skin, then forming it on a box brake.

Thanks,

Mike

-

What's the slot for? Getting the work piece back off?

-

Thanks for the recommendations. Picked them up on Amazon for less than a tenner combined.

-

Thank goodness, as I bought it last night. It was just half the price of everyone else I found and usually that spells too good to be true and it ends up being made out of tissue paper that burns my shop down.

I ended up getting a $10 ebay coupon, so it came out to $90 to my door.

I ended up getting a $10 ebay coupon, so it came out to $90 to my door.

I'm still in that earlier stage where I've read a ton of stuff, but only a 1/5th makes sense because I haven't done enough or it hasn't soaked in. I bought fumed silica last night and researched it for 30 minutes trying to figure out which one was the desired one - hydrophobic or hydrophilic. Something all of the experienced guys know from experience.

Thanks guys

-

ebay link removed

Am I missing something here? 1”x24”25’ for a $100 including shipping? Too good to be true?

-

I’m wondering if anyone knows if there are any reference materials on how to produce Celtic art such at Celtic Knots from rod. Specifically looking for order of operations, techniques, etc.

-

Anyone have a recommended regulator, pressure gauge, and hose setup for a dual burner setup? I know I need one that is adjustable from 0-30 psi. But is there a model/brand that is less prone to leaks, quality parts for adjustability. Is there a hose type that is better protected from stress and heat, or is it better to sheath the hose? I’d prefer to use something larger than a bbq bottle... do the larger tanks use a different connection type?

-

For Tweco Mig tips, is the threaded portion 1/4 28 thread? In looking at these things, I can’t confidently figure out if it’s 1/4 28 or M6 metric.

whats the proper drill and tap for these?

-

Just picked up a post vise that’s missing the mounting bracket. They are stupid expensive on eBay. Anyone have designs on period correct mounting brackets. The flat bracket with three holes is easy, but wondering about the steel wrap around the leg, shims, etc..

-

-

-

How is it used? Is it for bending bar stock?

-

Anyone have any experience with P-75 Black Beauty Forge Burner? I searched here and found only one reference. I'm a complete beginner, have read as much as I can of Mike's posts. Looking to make my first forge and planning a double burner box forge.

Is it adjustable? Is that what is meant by the draft shield?

Also, it mentions - "We do not provide a flare with our burners. Our burners are not a hand held torch, they go into a stationary device where a flare is not needed (the refractory lining creating the flare/flame holder)."

Does that mean that I need to create a conical shape in the ceramic liner? or a flare shape is not needed with these?

Air temperature vs. material temperature

in Heat Treating, general discussion

Posted

I'm wondering how the temperature of the oven relates to the material temperature and if they are always the same once the right amount of time has past.

So for instance, if you need to heat treat steel at 500 degrees for 8 hours, you set your oven to 500 degrees -

1. Is there a rule of thumb of how long it will take the steel to come to 500 degrees?

2. If the steel was in the oven when you started the oven to rise to 500 degrees, when the oven hits 500 degrees, does that mean for relative certainty that the steel is also at 500 degrees? Or by scientific principles, will the oven not hit 500 degrees until the steel hits 500 degrees as it's effectively cooling the oven air by being heated?

I'm thinking of using a ceramic/glass kiln to heat treat/temper steel since I already have it. But wondering if any of the above has to be taken into account when doing these actions.