-

Posts

81 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by LeMarechal

-

-

13 hours ago, Goods said:

How about making your single sided ball rivets a little longer and making the other ball separate with a countersunk through hole? That way you could peen the river right into the second ball and clean it up with a file (if needed).

David

That looks like an easy way for normal shops... Thank you for that!!!

The bolt an nut version sounds good too, but a little more complicate if you wish small diameter rivets. Maybe an advantage for applications where you

have to disonnect parts from time to time. Or for repair issues I guess..

Anyway, it's still a good idea!!!

-

Good idea,

thanks Thomas!

Here in Germany it´s not easy to get such photos because we have no such stores

that's why I never got this idea...

Here what I found to the fast:

[Commercial link removed]

-

First of all I like to point out that I´m not sure if the term ballhead rivet is the right in english???

Please correct me if this is wrong.

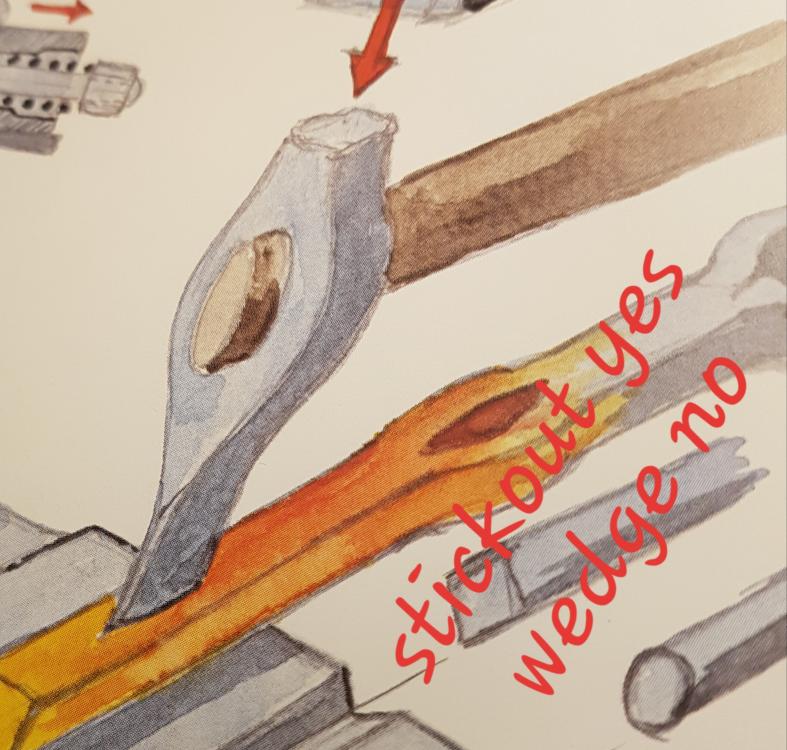

In one of the amazing Otto Schmirler Books I found this picture for an example of ballhead-rivets:

As this kind of work can be seen from both sides, I´m wondering if there is a way to rivet these rosettes togehter, ending up with two ballhead rivets, one of each side?

I can´t imagine that but I wouldn't be surprised if the old masters could

Does anyone more about it?

Greetings Sascha

-

Hi to all out there,

I'm currently dealing with how to make ballhead rivets. Until now I forged a little ballend at the end of some round stock, then cut off 1" or so away from the ball to get enough mass to form the tennon part of the rivet under the powerhammer using my tennon-spring -wage.

Now I´m searching for ideas for making a springswage to make the ballend and the the shaft in one step.

Find no examples how such a tool may look, nor how to prepare, preforge the stock for such tools....

Any tips?

Greetings Sascha

-

I know what you mean and I wondered if that long stickout would be disturbing at working.

On the other hand if you place the bolt too close to the end/edge of wooden things, you may end with splitting the wooden end ( bad writing style, I would be a terrible writer

)

)

There is a rule of thumb that recommend to stay away from wooden ends 1" or so...

But you're right I will see if it works

-

Hi Daswulf,

I think so too... will look around where I can find someone near to me who wants to do this job.

If I found someone I'll post some up to date pictures

-

-

-

All the important things about unsing the forge to minimize the scale have already been said.

But if it is too late to lock the stable door after the horse has bolted(hope that I´m using this aphorism in the right manner :) ), I like to give you an idea how to "rescue" these pieces...

Chemical scale removement may help you:

white vinigar works fine. I´m using normal 10%white vinigar from a normal food store near to my location. Stored in a plastic barrel. Leaving the pieces in there overnight is just enouh, even for heavy scale. In most cases you can wipe of the rest of the scale simply by hand/toothbrush under running water.

Maybe you won´t like the bright silver shiny surfaces you will get with this method?

Another drawback maybe that you have hurry up a little bit to make your pieces dry after cleaning under water, because rust will come up in minutes, even if you have dried everthing carefully, there is no much time befor it will get a thin rusty coating. So if you want to try it out it is recomandated to dry things good after cleaning with water and make your coating (paste wax ect...) immediately afterwards.

If you indeed don´t like this silvery look, go back to the forge and heat the pieces up to a dark red heat for rescaling to your liking. If you take the pieces out of the forge start wirebrushing until it is cool and you should end up with a nice, more blacksmithing like colour....

Greetings Sascha

-

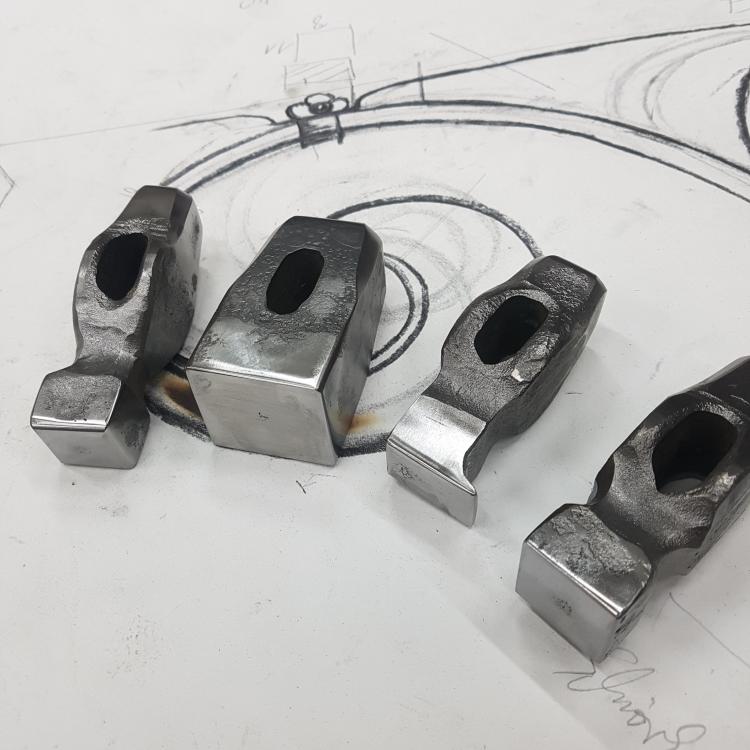

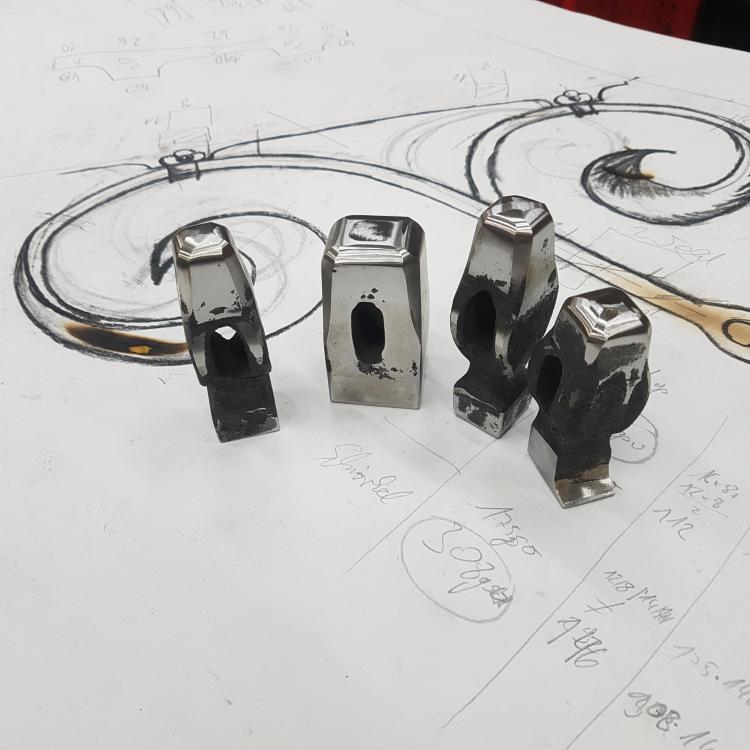

Made some different kinds of sethammers today.

The big cubic one is for use under my treadlehammer the smaller are more for use at anvil/postvise ect.

From left to right (above photography) you can see: straight sethammer with heavily rounded edges 1" square, sharp edges 1 5/8" square, sharp edges 1" straight, sharp edges 1" heeled sethammer...

Now have to search some fine wood handles. Here in Germany the traditional handels for top tool are made from oak or hazelnut branches... don't know where I can find.

If you walk into the next forest and cut off some branches you can get in big troubles if anyone noticed...

-

Cool to have that sorted out

these are those little detailed questions wich can become very soul-destroying for me if I do not can get an answer...

Now I can sleep much better

-

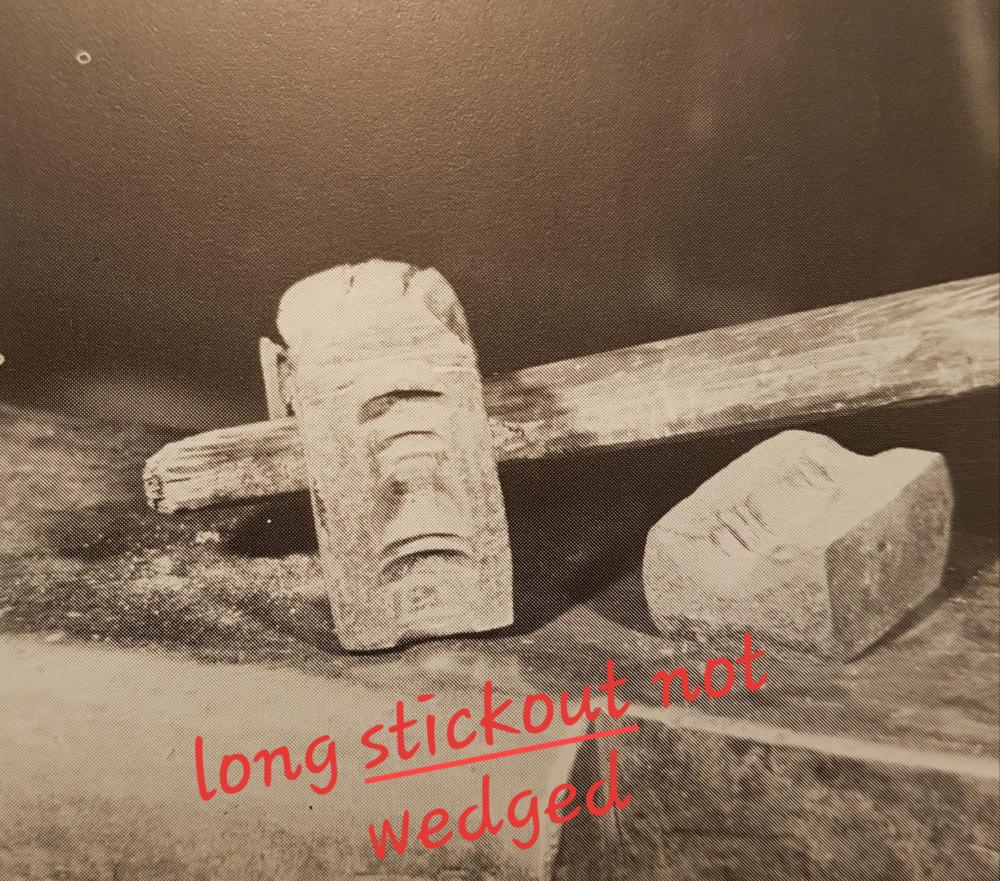

Think I found the answer

Here I copied such a statement for example:

Die Hämmer erhalten gewachsene Hartholz Stiele die aber nicht verkeilt werden damit bei schiefen Schlägen auf den Hammer keine Prellungen entstehen durch die die Hand verletzt werden könnte

Here I tried to translate with help of Google translator:

The hammers have grown hardwood handles that are not wedged, so that if the hammer is hit at an angle, there are no bruises that could injure the hand...

I'm sure everyone will catch the main idea

After reading this I think I missinterpreted the whole thing. It doesn't mean loose in the manner of something wobbly or so.

The point is, the handle itself should fit but then it is not wedged in place as usually done with handhammers.

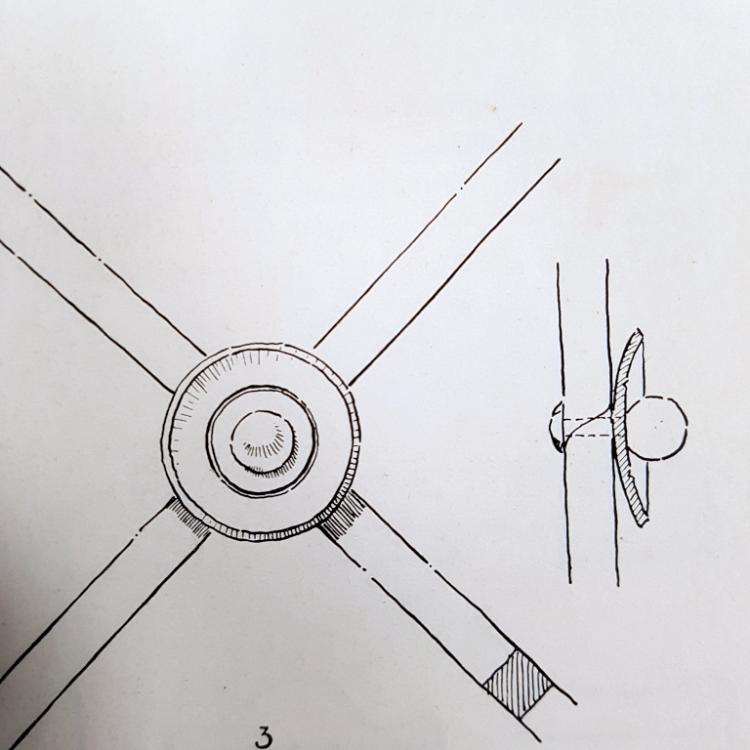

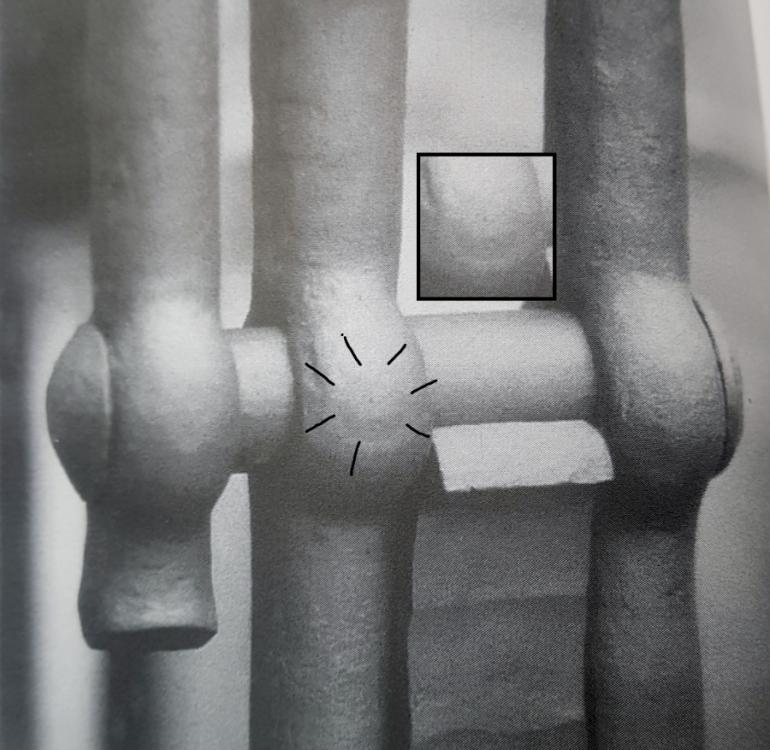

Furthermore I found in the book of -Otto Schmirler : the smithy's craft and tools -

some drawings and photographs where obvious stick out is noticeable, but no wedges.

So, I've learnd today to understand "loose" simply as not wedged

-

Hi Frazer,

That's my preferred method too if I make tools by myself. Wrapping around the tool not to tight and you end up with a little "loose"

But now I found some old tools wich I would like to use in future. And they all have hammer eyes. The special point of these eyes is, they are parallel and not hourglass shaped as necessary for handhammers.

I came across this topic, because in all German blacksmithing books this loose fit is always recommended to avoid bruising the wrists. However, they don't explain further how to realise this "loose" fit

Thomas, can you move these tools easily on the handle?

Greetings

Sascha

-

Yes that's an other idea.

Don't touch the swageblock, and use it for rough work. If it must be perfect then use a custom made bolster plate with nice clean rounded edges...

Thanks Thomas

-

Hi to all out there in the world,

I got a question about fastening wooden handles to top tools.

It is recommended to make the fit of toptool handles loose to prevent damaging the handle or hurting the blacksmiths wrist if an errant blow occurs.

Ok so far the theory...

But what does this mean in real life? I'm wondering how to fit the handle loose, but avoid the tool coming off the handle during using it?

I find it very annoying if the tool slips off the handle every few blows.

So, how do you fit loose

-

Hi Daswulf,

You're right I realy should make a photo. Comes tomorrow...

Today I try to drill the block:

No spirals, only grey crumbs and at the edge of the drilling no burrs. So Latticino is right, its a sort of grey cast iron.

I think welding is not possible/to complicate...

The only solution I could imagine is: milling off the upper 3/8"...

"Sharp" is not the right term for what I want. I know the problems with sharp edges...

But a little but more defined holes with slightly rounded edges would be nicer than what I have at moment...

I will pick a photo tomorrow

Thanks for now

-

Ok... i will do some testings.

Now its realy time to go to bed here. I'll post my test results

Greetings

-

1 hour ago, JHCC said:

Maybe things were different in Germany.

Maybe, maybe

The only new swageblocks you can buy here are made from "special cast iron" that's what the dealer wrote on his website...

When I found the block, it had very rusty surfaces and so I tried to grind the flat sides clean. That was a very horrible job. It was like grinding hardened steel, absolutely inefficient...

Can't remeber how the sparks looked like.

The only information about the german swageblocks I found is this "special cast iron" - statement

Sounds like something like ductile... normaly if here is something made out of cast steel, they would tell it...

-

Ok, will test it tomorrow.

Should I use special welding rods or could I use normal mig welding to fill the craters and flakings?

Greetings Sascha

-

Hi to all out there in the wide world...

My swageblock has very worn edges around its square and round holes.

I'm wondering if I could fix it by welding and grinding. Does anyone here got experiences with something similar?

Greetings Sascha

-

Hi to all out there,

as many people I have a shop that is nice but space is very limitted. My forge is a very compact one and it is mounted on wheels. So I can move it in the shop around when it´s not in use. The other reason for the movability is that I´m going on markets for craftdemonstrations from time to time...

Because I haven´t had a chimney in my shop I have to roll the forge outside, under the free sky and let it run there. Now I like to change this. My idea is to create a chimney thru the sidewall of the shop (indicated on the photo) and to find a way to easily connect/disconnect the hood of the forge to this chimney.

The length of the way the smoke has to pass thru is about 5meters. I would choose pipes of 12 inches ID

What I´m worried about is, if such a chimney will exhaust effectively enough to get the smoke and coal dust out of the shop without a fan? Does anybody have experiences with a temporarily connection between the forge and the chimney?

How did you solve this point? How much chimney should I plan on at the outside?

Greetings

Sascha

-

Hi,

Thanks to Anvil, Twigg als Frosty and all the others. Sometimes I tend to bit on such details and as long I can't find an answer it could make me crazy...

So thank you all for the patience! Nit at least because English is not my mothers language and so it maybe sometimes a little bit hard to find the right words to subscribe what I mean... I'm sure that, what I'm writing, often sounds a little bit clumsy for natural english speakers:)

I think we found a few very good points here so far. I will find a projekt where I will try out the tipps I got here and then I'll show it here...

At Anvil:

Rack and roll is a good sentence for a Blacksmith-TShirt I guess

Greetings from Germany

Sascha

-

Hi twigg,

yes absolutely too much for shrinking, but also much too little for assembling. :)

Alignment is always one difficulty and for that a little clearance is necessary. But far more than what is needed for an interference fit...

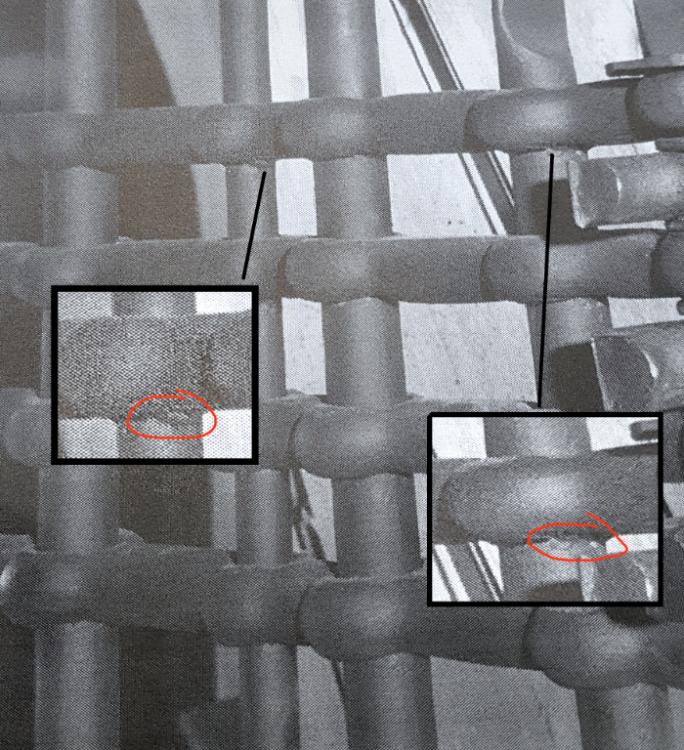

I tried to make two more photos to show a little detail I found after looking at the original photo with a magnifying glass. Sorry the poor quality of the pictures but the originals in the book are not better

Above you can see a crop of one of the photos out of the first posting... can you see this round shadow where I marked it. For comparison I copied the area without markings.... Maybe a blindrivet?

This is realy poor in quality but I guess you can see, that there is "something", a little irregularity could be a little welded region perhaps?

-

This is really a nice job. And a cool project. A very impressive example of what is possible if people with visions work together. Thumbs up

greetings

Sascha

Ballhead-rivets top and bottom tool

in Tools, general discussion

Posted

That is much too easy