Eventlessbox

-

Posts

303 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Eventlessbox

-

-

Very helpful. Follow up question. How much of a difference would be noticed between a 118# and a 176# anvil assuming other factors are similar.

-

Not sure as of yet. Is a three hour drive. Owner has had it for 30 years, when asked said rebound was good. I wanted to get an overall concept before I made the three hour drive. Price is in line with my areas market. And weight is 118# so within the range I was looking for(I use a 2.5# hammer)

If not this one I have a lead on a 176# anvil. But it has no discernable markers marks.

-

Anyone have any advice on the quality of Wilkinson anvils?

-

That's really cool looking. Nice.

-

Meanwhile in Florida,

March 14th, 85° with a light breeze.

-

I will be adding pictures and documenting through to forging. The forge even after purchasing refractory is still coming in less then my first forge I built myself. If it works as well then maybe I can help some starting Smith's have a less expensive start up.

-

Thanks for sharing this. That deffinatly is cool looking. Makes me wonder if it was purpose driven or it it was a decrotive embellishment. I also notice that the multiple holes in the top seem very purposely spaced. So curious.

-

After a few recent threads it was suggested that those of us that went the commercially manufactured forge route share our experience.

Item one, and this is huge, unless you spend the big money for a manufactured forge,

They are not plug and play.

When your forge arrives there are steps to take and for a good experience products to buy before your forge is useable. The forges 101 thread covers this extensively.

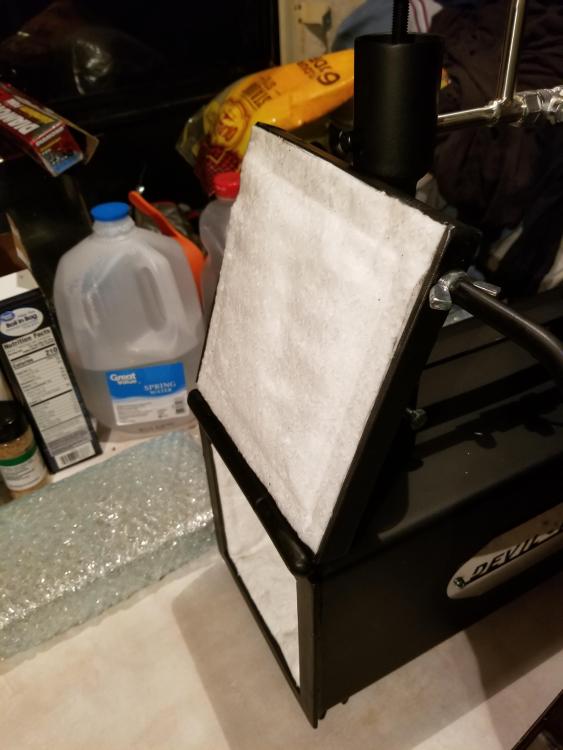

Devil forge now comes with a ridgidizer, which appears to be a very fine paint on clay. This is the step I just completed.

After this step I will still be applying a layer of Kast-o-lite. And then most likely a layer of IR re-radiating coating.

So while the forge arrived very quickly I expect to be weeks before actual usability.

-

Maxwell. Thanks for the spot. I'll make sure I check that when I do final hookup. Figured the slight price difference was worth having the door.

-

Alright. Awsome. Was planning on ordering some plistex from Wayne so that should be great.

-

The system merges replies automatically to help with bandwidth and storage space. Helps the server juggle all the different posts.

-

That is adorable. Any thoughts on paint color?

-

-

-

Ok. I was thinking if I flipped same day it would only be with the three sheets of lexan already in place and braced before the flip, then finish last surface and put final sheet in place. All supported.

Just concerned about having something keep me from getting to the last side next day. With work and the tiny house and special needs kids finding time two days in a row can be a challenge.

-

Sounds like a plan. Just to cover all bases; other thought was using some scrap lexan I have, release agent(read crisco), put floor and two walls. Brace walls with wood spacers then flip for roof. Would this get me a smoother surface?

-

Ok. I was thinking of doing two adjoining sides, allowing to begin to harden while supported up on a corner( two sides forming a v) then flip and do other two.

-

So I have a square body devil forge arriving. I have my bag of Kast-o-lite. What I can't seem to figure out clearly is do I need an inner mold for the Kast-o-lite during dry-out to keep it against ridgidized wool or is that just for things like ribbon burners? Can I just trowel it into place and have it hold?

As always thank you all again in advanced for sharing your wisdom.

-

JHCC,

I hear you there. I run on caffeine and happy thoughts.

When people refer to the weight of a hammer is it just the head or the head plus the handle?

-

Awsome. Thank you both for the feedback. Found Kast-o-lite local and am ordering some colloidal Silica tonight(not sure I trust the stuff they send and the silica isnt expensive). Now to just wait for it to travel Europe like a spoiled teen.

-

Lou,

One thing I know we are curious about, how hot was the outer shell? Trying to decide if I want to add another Inch of wool when mine comes in.

-

Woooooo. So exciting. Loving it.

-

Guess that explains why the forged in fire guys always have trouble with their forge welds.

-

Icandry,

For the devil forge have you looked on ebay. Just got a 2 burner with door for $235. Would leave you room for kast-o-lite and merkolite from wayneco.

Wilkinson anvils?

in Anvils, Swage Blocks, and Mandrels

Posted

Pp# is almost identical. On just a visual/word of mouth basis the larger anvil seems to be in somewhat better condition. But thanks to extensive forum homework I know looks are a very small factor compared to actual condition.

I intend to do a lot of smaller ornamental items. Leaf hooks, pendants, hinges, gate latches. I think the blade world around where I am is supersaturated enough.

Thank you all for the feedback as that really helped me make a more informed choice.