-

Posts

47 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Enewguy

-

Just a box of dirt, or a simple side blast forge

Enewguy replied to Charles R. Stevens's topic in JABOD - Just A Box Of Dirt

Stick around, even if you just lerk. You can learn A LOT from these folks. I have in the past few months. -

Charcoal briquettes? Correct me if I'm wrong guys but won't that create more fireflies and be incredibly less efficient than lump charcoal? Especially if you blow "hard" air at it??

- 32 replies

-

Another place to buy coal

Enewguy replied to Enewguy's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Well it turns out I've got tomorrow off. So I'm thinking I might have a trip to make. -

Yeah, I was kinda thinking the same thing. Not sure of the content of the metal. I've personally hit 6 inch shot rock with the same style and type while morning along the highway right of way and didn't dent them. (not on purpose of course) I'm not into making knives yet. Since I'm just starting out. Since the blades are perfectly new and I was thinking since I live in farm country I know a few folks that might like to buy them.

-

Lololol I actually told my son that today. We finally got a chance to fire up the 55 I built. He was itching to make something so I suggested a bracelet for his girlfriend. At one point he started to drop it from the vise. for some reason he thought he should catch it by pinning it against the workbench with his hip. Lol I yelled let it fall, he did. Then I quoted you. He kinda laughed as he realized how dumb of a move that was.

- 14 replies

-

- prevention

- safety

-

(and 2 more)

Tagged with:

-

-

Just curious Glenn, as I've been reading A LOT of older posts on this site. Ever get tired of saying it? it's even been said to me when I was burning my steel. Sun, I was having a kinda sorta related issue... It wasn't so much of an ember problem but I was blowing way way WAY to much air into the fire pot. Every once in a while I would get a poof of embers when I moved the steel in or out of the fire. Yep, that spot. But the air I was blowing in was through a 1/2" pipe with a mattress inflater taped in the end. So my whole evil spot was much taller than if I had been doing it properly.

- 14 replies

-

- prevention

- safety

-

(and 2 more)

Tagged with:

-

I agree! I think I already posted a picture of just that... A failure at making tongs.

-

Another place to buy coal

Enewguy replied to Enewguy's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Thanks Glenn, after a bit more research the coal comes from the mulberry mine just south of KC. -

I didn't realize there was such a thing Lol. And I still haven't had time to use mine yet Glenn, the build was as far as I got then, the weather came in every couple days since mid last week I'm out plowing the roads again... Another week and a half and I change jobs so I'll have more free time and no standby time The "Real Coal BTU and analysis" post on this site might help some, but you need to find out what mine it comes from See the previous post in this thread from JHCC it will explain

-

Another place to buy coal

Enewguy replied to Enewguy's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

I actually live in Kansas. Although the Missouri line is only about 45 minutes. The place I mentioned is only about an hour's drive for me though. I finally found the local club. Their in Paola ks. Their only about an hour away. The next meeting is this month. Unfortunately I'm not gonna be able to go check it out, to busy with life right now. Maybe in the next couple months I can go, once things calm down a bit. -

Another place to buy coal

Enewguy replied to Enewguy's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

I have tried to look on the abana website and can't get any info. The only thing I see is "membership info is no longer given out". It's gonna be a while before I can make the trip to that particular facility to get some anyhow since it's a couple hours away. I'm changing jobs in a couple weeks (I'm putting in my 2 week notice tomorrow). The wife and I are taking some classes to get foster care licensed. I just don't foresee the trip in my near future. Simply to busy with life right now. I was more looking for input if you guys think it's a good price and a decent quality coal. What is the desirable btu rating? Of bituminous? -

Another place to buy coal

Enewguy replied to Enewguy's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

I figured that was the general rule and why I didn't post it. What is considered a good btu rating? -

So I have a question as to the cost of coal. Like many I bought anthracite from TSC. During my quest for a solid fuel, my son found a place in Western Missouri called Continental coal company. He said he called them and it was $65 a ton. Then he couldn't find their number. My local TSC doesn't stock either. No anthracite, or coal of any kind. The stuff I got, I got while out of town visiting family. Finally I located the phone number (according to Google) for them and called. The number listed was their fax machine. After a bit of searching I located another phone number and called it. (I suggested an edit with Google that's in review) The lady answered by saying "Continental". Knowing I finally got the right number I asked if they sell to the public and she said I needed to talk to a gentleman named Chris and gave me his number. I called Chris and asked the same question. Yes they sell to the public at $65 a ton. No minimum. He said he has people come in and buy a tote full for forging with and some that being in trailers. He said it is bituminous, about 11k btu and I think he said size "0"...? Still not sure if I heard the size correct. So here's my question, go or no go? Btw, I have the phone number. IF I'M ALLOWED to post it, I will. I'll wait on admin or Glenn to give me the ok for that.

-

The age old question, gas or coal

Enewguy replied to Zeba's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

I can attest to that. If you've never smelled burning coal, it stinks it has a certain odor to it. You know you're inhaling a certain amount even outdoors. There's a saying for that. "If you can smell it, you're inhaling it." I would agree with frosty, use it outdoors until you can get proper ventilation. -

I managed to get a 55 gallon drum this week that used to have hydraulic fluid in it. I was also able to get 2 different size brake rotors. I started by overflowing it with a garden hose since I could tell there was some fluid left in there. I would rather have water on the shop floor than hydro fluid. Less chance of busting my rear from sliding around. I then cut the front open. Used my plasma cutter to Cut the bottom using a smaller brake rotor as a template. Flipped it over cut a slightly larger hole in the top using a larger rotor as the template Put the large rotor in the bottom hole. It sets perfect in the smaller hole with the flange sitting on the drum floor. Next I built a fire the boy scouts would be proud of. looks worse than what it was. That's just the hydraulic fluid and paint burning of the outside of the drum. After it settled down, I cut a V in the front so I could rest my work piece on and opened it up a bit along the top of the front opening. Since it was all cardboard and paper in there burning and dinner was ready I let it burn out and called it a night.

-

How to forge a flatter.. No swage block used..

Enewguy replied to jlpservicesinc's topic in Tools, general discussion

Great video, I also watched the basket handle video and subscribed to your feed. Thanks jlp -

I'm inclined to think i put it there. That was the third attempt at getting it started. I'm thinking when I was getting irritated not making the boy scouts proud, I dug out a bit to much and possibly to far to the side to start over. I can guarantee I will... How else will I learn from them?

-

I just did that Tuesday night. Fire ball wasn't where I thought it was.... Oops That WAS the bottom of the box. But that's ok. I'm going a different route thanks to another design that caught my attention and someone letting me pick their brain a bit. The weatherman is calling for more snow this weekend so I might have to work but I'm excited to start the other project.

-

Nice Fab job, looks like a nice setup!

-

3D printed plastic burner experiments (photo heavy)

Enewguy replied to Another FrankenBurner's topic in Gas Forges

So they used to make a fire hose nozzle "cellar nozzle" that spins. I found a video called cellar nozzle at work on YouTube Is your burner NA? If not you could make a 2 piece tube with a piece inside that spins to create the vortex. Of course you would have to play with the inner nozzles angle a bit. If it's NA, I wonder if straw like tubes going around and around within would allow it to start spinning enough to vortex as it excited the main tube- 863 replies

-

3D printed plastic burner experiments (photo heavy)

Enewguy replied to Another FrankenBurner's topic in Gas Forges

Fascinating...Just curious, have you tried one with a spiraling fins all the way the length of the tube getting more aggressive as it goes except the last bit? Kinda let it free flow spiral out the end.- 863 replies

-

Built my first Jabod ( pictures included

Enewguy replied to Enewguy's topic in JABOD - Just A Box Of Dirt

The all thread isn't even warm, it was just a convenient flat place to set it down. Also is stainless. I use it to put through the center of a roll of barbwire to hold with the 3 point in the tractor. I was kinda thinking along those lines frosty, that I need to put in a waste gate for some of the air flow. The flames in the pic look awful aggressive. I'm thinking about changing to to 3/4 with a 45 elbow and a ball valve on it. As for the smell, maybe it is suffer I'm smelling isn't any galvanized in there of my doing. No there's not any zink smoke. I looked specifically for that. Once it gets going, there's not much smoke at all. Not that I can see anyhow. -

Built my first Jabod ( pictures included

Enewguy replied to Enewguy's topic in JABOD - Just A Box Of Dirt

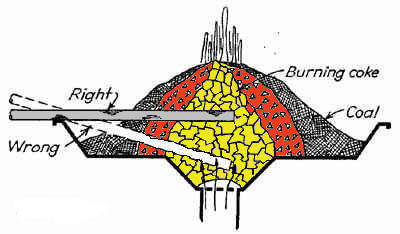

Can someone explain air flow/supply with a side blast JABOD. as in when to have the flow on and off. I built another fire in mine tonight, I think I might be leaving the air on at the wrong time. Even when placing my work piece the proper way like in the diagram, It will get really hot really fast. Like sparkling hot if I'm not careful. I thought it was because I was using rather smaller stock 3/8 round. But a friend gave me a RR spike today so I decided to mess around with it. yes I know the whole argument about messing with them (mixed metal) but that's not the info I'm after right now. With in 2 minutes tops it was starting to throw Sparks. And cook off. So my question is, should the flow be turned on when the work piece is out of the fire ball? To keep the fire going. Could it be because I'm using half inch pipe instead of 3/4? It was what was on hand last weekend. Does the fire look right The first is with air on, the second is with it off. Thanks again -

After posting that, I read another of your posts explaining it in great detail. I think the problem I had was a combo of placing my work at a steep angle, and having to much air flow since I was using an air mattress inflator. Btw, thanks for hosting this site where we newbies can come to learn from ALLOT of very educated/experienced people.