-

Posts

35 -

Joined

-

Last visited

Contact Methods

-

Website URL

www.harvestgapforge.com

Profile Information

-

Gender

Male

-

Location

Weaverville, NC

Recent Profile Visitors

-

HarvestGapForge started following First Railing Project? and What finish should I use for blades and knives?

-

Don't worry about 5/8 being too heavy. Most people consider it standard. I start from 5/8" x 8" blanks to make just about any set of tongs I need. I learned tongs a couple of years ago from Dave Custer at Campbell Folk School.

-

I'll definitely do that and with the next batch I make. At first for the forge weld at the poker end I was folding over the end, welding, and then splitting. But that made it too time consuming and difficult to position on the horn to get a nice consistent poker end. Now I just forge a taper, make a scarf, tack weld it with electricity, and then put it in the coal for the forge weld. I've sold and given away about 20 or 25 of these since the fall.

-

.thumb.jpg.9192bd4c7ad116cf8f6005af51f7654b.jpg)

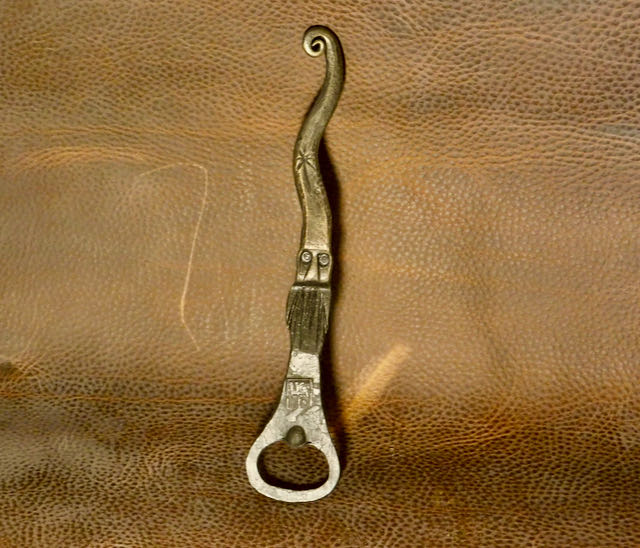

Show me your Bottle Openers!

HarvestGapForge replied to Arbalist's topic in Blacksmithing, General Discussion

Typical wizard. I keep trying to make them and my dragons look fierce but apparently I have the curse of the happy/goofy wizard and dragon face. -

I've done very well with fire pokers this past fall and into the winter. I think it has to do a lot with COVID and people are spending more time time relaxing at home and want to do it with style. I'm going to have to try one with a wood handle. How did you fix the handle? Is it glue only or is there a pin that we don't see? Here is what I have been making with variations on the handle and twists, and sometimes if I have the time for it I cut Rubik's twists. I see you are in Lincolnton. I'm located in Weaverville.

-

.thumb.jpg.9192bd4c7ad116cf8f6005af51f7654b.jpg)

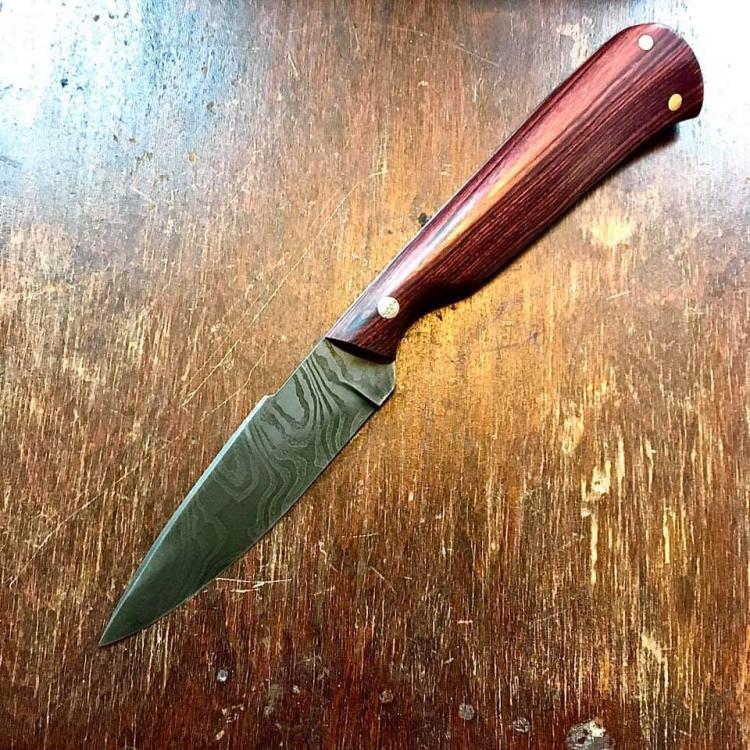

What's your latest blade look like? Post em and let us see.

HarvestGapForge replied to HondoWalker's topic in Knife Making

I recently made this as a submission for an art scholarship which didn't pan out. Feather pattern 1084/15N20 blade with brass, copper, sambar stag, and curly maple. This is also the knife that taught me to always put a pin through the tang. Frosty, I'm sorry that we never met last summer when I was up in the Big Lakes area. I stayed with friends on Crooked Lake which inspired this knife, which I call "Crooked Lake." It is one of my humble offerings on my newly launched web page. OR -

I am Harvest Gap Forge. I wanted a "place" name. I was 14 when I named it and didn't want to name it after an actual place because who knows where I will end up living. I'll be able to move my business anywhere just about - maybe not the plains or the beach - but that's ok. I like the mountains. Harvest Gap. It is a great place that can be anywhere because it exists in my mind.

-

I've made a set or three of tongs from rebar, and still have one that hangs on my rack that is useful at times. I will say that rebar is far better for bottle tree stands than it is for tong making material.

-

.thumb.jpg.9192bd4c7ad116cf8f6005af51f7654b.jpg)

Just Getting The Ball Rolling

HarvestGapForge replied to Mulebrain's topic in Blacksmithing, General Discussion

Great score! I've been sort of looking for a swage block like that - happy to see they can still be found for a reasonable sum. You might onsider connecting up with the state ABANA chapter Phillip Simmon's Artist Blacksmith Guild. There are a lot of active hobby and professional smiths in your area. The next state meeting is Dec 7 in Greenville, SC. Also, the American College of the Building Arts has running classes in basic forging and they have special topic workshops too. -

.thumb.jpg.9192bd4c7ad116cf8f6005af51f7654b.jpg)

Where to buy

HarvestGapForge replied to Phoenix Action Films's topic in Blacksmithing, General Discussion

Find a local welding shop. Most have stock to sell and are often willing to get you some bars delivered when they put in their next order. -

.thumb.jpg.9192bd4c7ad116cf8f6005af51f7654b.jpg)

Help with slit/punch

HarvestGapForge replied to HarvestGapForge's topic in Slitters, Punches, Drifts, etc

The tools are clean. I have a grinder and can touch them anytime. I think that I am just not keeping the tool cool enough and it is upsetting just enough to get stuck. I also made my own bee wax linseed oil lubricant. I am using a tire hammer which does hit fast, and I'm realizing there are a few tricks to the technique. I'll play around more with the geometry of the tool too. I have to get a few axes and hammers ready for a craft show ASAP so I am going to get them done and open the eyes with a striker. I will come back to this soon, however. I also think that there is not enough space between my dies, so I am going to think about making a shorter bottom and try to get some space this way. Brent Bailey is great. I met him at SBA Murphreysboro last year where he along with a couple of others helped me make a 3 1/2# rounding hammer which was the second or third time I did something like that. -

.thumb.jpg.9192bd4c7ad116cf8f6005af51f7654b.jpg)

Help with slit/punch

HarvestGapForge replied to HarvestGapForge's topic in Slitters, Punches, Drifts, etc

A little bit of coal. -

.thumb.jpg.9192bd4c7ad116cf8f6005af51f7654b.jpg)

What did you do in the shop today?

HarvestGapForge replied to Mark Ling's topic in Blacksmithing, General Discussion

What I did tn the shop today: I stuck these together and have a specific question about it over in the Slitters/Drifts category. -

I have made between 15-20 axes and hammers punching with a striker and a reformed ball peen hammer for the punch and I've never had any trouble. Now I am trying to make top tooling to for power hammer. So far this is my result. The larger piece is made from Hi-Tuff and I realize that I made it too big and I guess I shouldn't be surprised it got stuck, the smaller one is 52100 and I expected that to work. (Actually I expected both to work). Axe material is 4130. What am I doing wrong? Is there a basic technique difference between punching under power, or am I going wrong with the tooling. The tool is stuck pretty good in both pieces.

-

I got a near new TFS 250# for a price that was too good to pass on. It is basic but and I can't complain. 1" hole to fit my bottom tools so I didn't have to make new ones. That's a consideration. It is my first new anvil and my first shop sized anvil. They are available and if I remember you can get a 300# double horn from them. An anvil that I like a lot is the 220# Perun Artisan Anvil with the drawing table. Blacksmith Depot has them in stock for a reasonable price. Dreaming, I would design one similar to that but with a double horn and weighing a lot more than I think that would be ideal.

-

.thumb.jpg.9192bd4c7ad116cf8f6005af51f7654b.jpg)

Show me your blacksmith pets

HarvestGapForge replied to Glenn's topic in Blacksmithing, General Discussion

Vinne Barbarino, the anvil surfing Boston Terrier. He is a little more comfortable on my new shop sized anvil