toadboy65

Members-

Posts

26 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Western North Carolina/Southwest Colorado

-

Interests

Artifact conservation.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Power hammer build

toadboy65 replied to toadboy65's topic in Power Hammers, Treadle Hammers, Olivers

Right now, about 30lb. Plus the weight of the top die. -

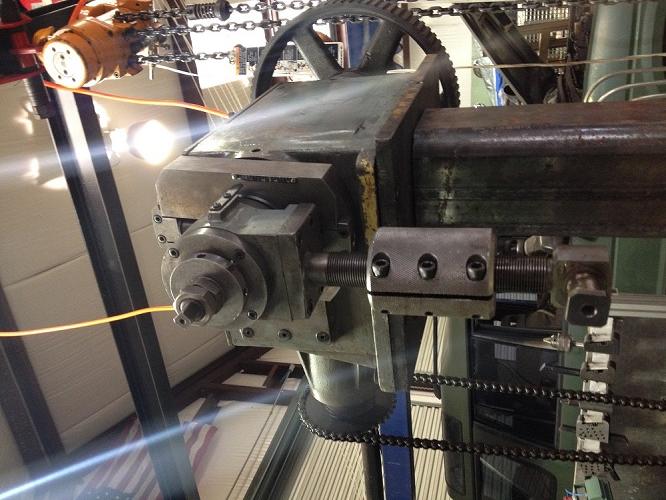

I have been sort of letting this project evolve for some time, but it is starting to come together now. I started with the main gearbox, which came of of some kind of giant, industrial squishing machine. I mounted that on a steel post, and started figuring how to make the rest with scrap in my shop I made a couple of super basic die sets out of 440 stainless- The mechanism allows me to adjust the space between the hammer and anvil on the downstroke from zero to about 2 inches, which can be increased a little more by removing spacers under the anvil. I can also adjust the amplitude of the swing by about the same amount. Today, I temporarily attached a slow speed gearbox and motor to it, and ran it for a couple of hours to tweak things and look for friction. What I have not done yet is design and build the lower drive and clutch. I have a nice big flywheel, and plan to have the motor drive the flywheel on the clutch shaft, and have a dual v-belt system to drive the main gearbox. It would be nice to have a cone clutch or the like, but right now I am planning to use a couple of 440 disks, one of which will have brake lining riveted to it. I have no idea what the optimum striking frequency should be, but I have a pretty good assortment of gears and pulleys, so I can play with that a bit. Advice or criticism always welcomed -T

-

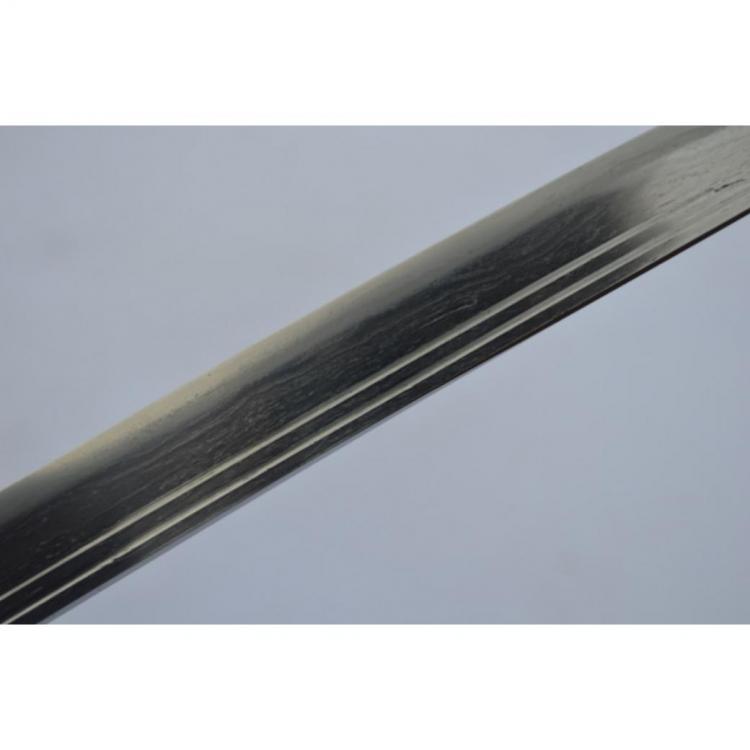

So here is the seventh knife I have produced since I made and started using the forge. Also, my first serious anodizing job. The blade is D2, with a black oxide finish. Scales are micarta, and gold anodized aluminum and stainless hardware. Lots of milling involved on the aluminum, and the fuller is milled as well. I have carved fullers in with a sen on previous knives, but I wanted to give this one a space program feel. :

-

Die type suggestions

toadboy65 replied to toadboy65's topic in Power Hammers, Treadle Hammers, Olivers

One of the cool things about the gearbox is that you can adjust the amplitude of the hammer swings, while keeping the apogee(?) of the swing at the lower anvil, or wherever you want to set it. There is actually a lot going on in the gearbox, which I have not really fully explored. I have the platform mounted about 2 meters high, attached firmly to an internal sleeve inside the vertical square tube. Once all the problems are solved, I will beef up the supporting structure. I do want to be able to take it apart, as it will be way too heavy for my hoist. My next step is to build up to the bottom die, as well as figuring the spring arrangement out from the junk in my scrap pile. I am not really worried about the drive motor yet, as I have lots of sprockets, chains, and gears on hand. That should be the easy part. So anyway, any die suggestions? ?? -

Die type suggestions

toadboy65 replied to toadboy65's topic in Power Hammers, Treadle Hammers, Olivers

-

After I learned how hard it is to make good damascus with a hammer , I have started to build a power hammer. Most of it is pretty straightforward, but I would like to build it to accept commercially manufactured dies, if necessary. I would like suggestions on what type of dies I should design for, and the specific dimensions. The hammer is going to be in the 30 lb range, give or take. I am using the gearbox from sort of giant squishing machine I found at the scrapyard, so it is pretty beefy, and it has adjustable stroke. So far I have built the base and height adjustable pedestal, mounted the gearbox, and am working on the striking shaft, which will be three inch hardened steel rod.

-

request for heat treating temperatures.

toadboy65 replied to toadboy65's topic in Heat Treating Knives, Blades etc

Finished the blade- I made some mistakes, but hope to do better next time. I am happy with it as first attempt. -

request for heat treating temperatures.

toadboy65 replied to toadboy65's topic in Heat Treating Knives, Blades etc

I did it today, using Kevin Cashen's numbers. I may have put the clay on a little thinly, or too thick. There is certainly some hamon activity, but I cannot know what polish will show. If I had been color case hardening, it would be a great success. Lots of color. Here it is just after quench: -

request for heat treating temperatures.

toadboy65 posted a topic in Heat Treating Knives, Blades etc

I have been reading the stickies and watching youtube videos, and the result is that I am confused and have a headache. My normal method would be to make a bunch of test pieces and experiment for a few months to come up with a process, but thought it could not hurt to ask here instead. What I want to do is heat treat the tanto I am making to create and maximize a hamon. But I want to do the process in my kiln, using numbers instead of expert intuitive blacksmithing skills which I do not have yet. What I have is a piece of mostly 1080 damascus , about 5mm thick at the thickest point, and I left about 1mm flat where the edge will be. I have satanite to use for blade clay. I have always used water or motor oil for quenching, but will probably try to get better quenching oil. -

I don't bruise easily, and I can use all the advice I can get. My idea was to cut the grooves, then do final thicknessing of the blade, to leave sharp boundaries on the grooves. I started sanding in some bad spots, but am now burnishing with the steel spike. I have not done any real work near the edge yet. I was afraid that my grooving work was going to be so disastrous that I would have to start over. I did practice grooving on a piece of steel, but it was softer than the blade I am working on. Also, I made the cutting bit out of HSS. I will take the time to make a carbide tipped bit next time. And I probably should gone ahead and put a decent handle on the tool. Thanks for the input.

-

I made a sen, which worked surprisingly well. I also made a little holder with a reground drill bit as a cutting tool. I ended up making some mistakes, so now I am working on one wider groove instead of two. It is disappointing to stray away from accurately following my original goal, but this is my first time making my own steel, and I guess I can use this as practice for my next attempt at accurate historical replication. Here is the grooving tool, mostly made of stainless steel: After roughing out the grooves, I am using this little spike I made to smooth out the grooves: The biggest issue I have is that the bit in the grooving tool tends to skip a little unless it is kept super sharp. I am working from the muni down. My understanding is that I should leave at least 1mm flat on the edge before tempering. I have a pretty good thermostatically controlled kiln for the hardening process, so hopefully i can get the hamon process right without screwing up too badly.

-

Here is the lump as of today: I am still working on basic geometry. It turns out to be not as thick as I had liked after removing hammer marks. The ones closer to the edge should be gone once I finish working that part of the knife. Or so I hope.

-

I am now working on that, thanks. I was about half way to inventing something similar, but with a little carbide "tooth" to cut the grooves.

-

So, I am trying to make a tanto, Kamakura period style. I have made the steel, and am closing in on the desired shape. I would like to put "hi" grooves on the sides, but have no idea whatever how to do this. Any help would be appreciated. Here is what I am trying to achieve:

-

I used a mild steel canister 5cm x 5cm x 10cm or so. Filled it almost completely with the spring steel rods, then added 1080 powder bit by bit, shaking it to settle and fill the voids. I attached a steel rod for a handle, drilled 3mm hole, then immersed the whole thing in used motor oil overnight. Once it had soaked in the forge long enough, I started hammering. I do not have a power hammer, but I do have a shop press. The press is of limited use, because it is too slow to be much help. I did press the billet a couple of times in the early stages, but have mostly hammered by hand since I took the canister off. I used borax after removing the canister, but that was probably unnecessary. As of today, it is about 25cm x 4cm x .5cm. It does not seem to have any voids or delamination, and I can no longer see the "grain" of the original materials. But the amount of hand hammering I have done on this is just crazy. Also, I am sort of winging it as far as technique. I may be missing steps or shortcuts, or doing unnecessary work. I am working solo, and do not have a mentor on this. I tend to set absurd goals for myself, then pursue them with fanatical determination until I succeed. My first real blacksmithing project was when I was in college, and spent a couple of years making a percussion rifle using Foxfire #5, with a small coal forge on the balcony of my dorm. (The fire department eventually got used to me). Here is that rifle, if anyone is interested: