hobb0042

Members-

Posts

19 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by hobb0042

-

Thanks for the quick responses, Deimos I would be looking for pieces to work on not melting, great tip on the roofers Stash thanks guys

-

Hi all in looking to make some small items using copper details such as copper rose petals and fashioning copper strips into some sort of decorative bow, my question is where would be the best place to source copper, second hand? Flea markets, old reporposed items? Or buy new fromocal metal stockist any suggestions greatly appreciated thanks all

-

TIG OR MIG the age old question help please

hobb0042 replied to hobb0042's topic in Welding Equipment

LES L, thanks very much. Im thinking of going for the 3 in 1 -

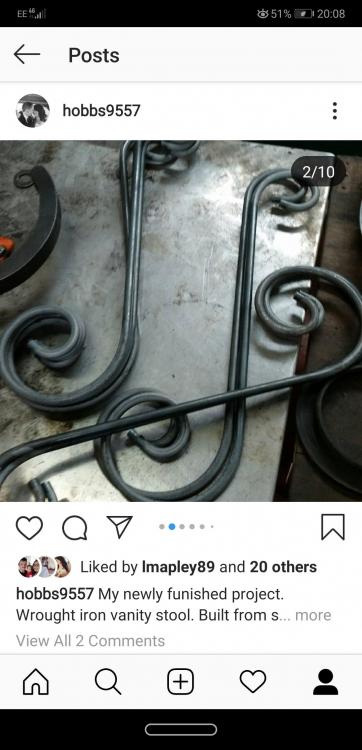

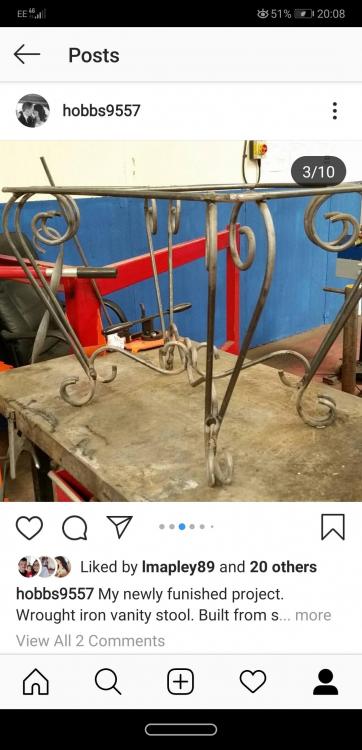

Hi all this is a bit of a throwback post to when I made my wife her vanity stool. We couldn't find anything suitable or would look like it would last. So what better than to use it as an excuse to make one myself. As if I need an excuse. Not really forged I wasn't "there" yet but I did have some hand tools and a handy workshop package purchased from metal craft products UK it was they're XL workshop package and included a scroller. The tools were easy to use and allowed for cold scrolling. Then made a sort of jig to hold legs in place while I welded away. This is the project through its stages plus upholstery which I gave a got at. I don't think it turned out too bad. As always there are things I na project you look back and would like to change such as flattening and lengthening the ends to add a more appeasing finish. Let me know what you think guys hope you like it thanks for taking the time to take a look. Long post over.

-

Hi All so a out a year ago I got in touch with a seller through fleabay who was selling a triple burner gas forge. On the off chance I asked if he had any other equipment and he told me he had this power hmer he was going to list but hadn't quite got round to putting online. Anyway after some negotiation we agreed a price and he delivered it from France. He was visiting family in my own city so decided he could bring it back with him. Awesome. This was his creation that took him many hours and redesigns and had been using well for the past ten years he was only selling because his wife agreed if he could sell it he could get a real power house of a power hammer. Anyway this is now mine and although I haven't been able to use it in some months due to my workshop in limbo I wanted to post it to show you guys and live in hope I can get it back set up and running as soon as possible. I'm not sure on the specifics of the power and the weight behind it but he made many things over many years and I hope to get it back in working order soon. SVID_20191105_200724_1.mp4

-

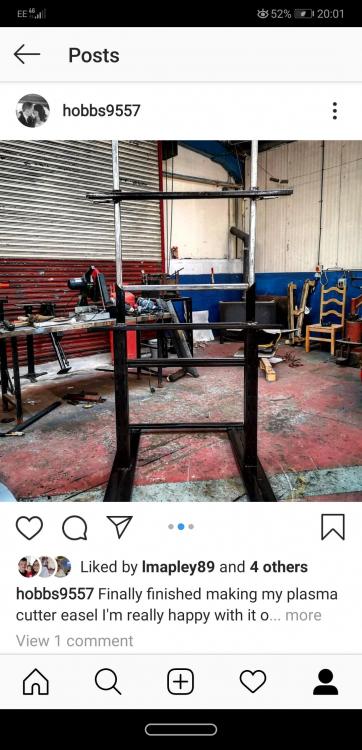

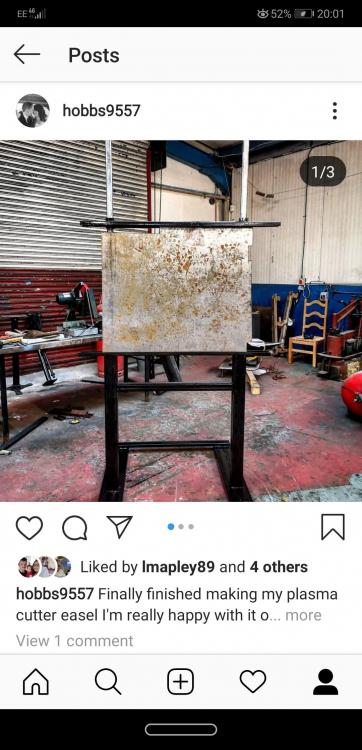

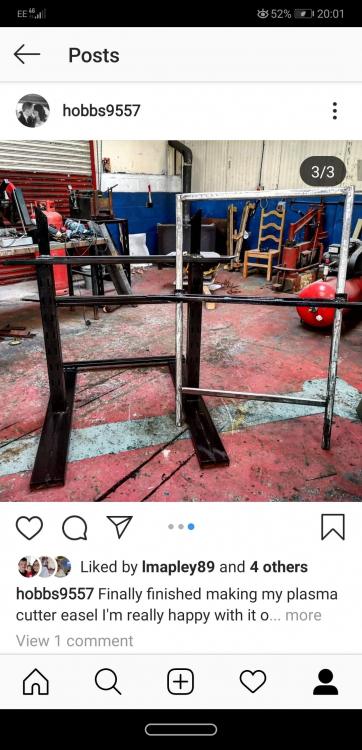

I know I'm dragging up an old thread bit thought this might be of help. Here's some photos of what I made for cutting out my plasma panels. Hope this helps. If you would like to discuss further drop me a message

-

TIG OR MIG the age old question help please

hobb0042 replied to hobb0042's topic in Welding Equipment

Thanks all. my projects would be 90% steel using various thickness round bar 6mm upwards and only the odd bits of copper etc for accents on the pieces. I think Mig would best suit my needs overall. (My preference for supplier is R-tech supplies in the UK. I've had good experience with r tech in the past owning both they're plasma cutter 30amp and 175amp arc welder.) They also offer a combi Mig Tig Stick I've attached a link: https://www.r-techwelding.co.uk/mig-welder-inverter-with-mma-dc-tig-240v-250a/ Question: Has anyone had good experience with these types of machinery? I've always thought something that offers multi use packages weren't great in any one field. But I would like to hear of users experiences. Alternative would be buy a 250amp mig and try to attach the copper via brazing. Question: I was wondering about brazing the copper to steel using a flux and small blowtorch. Would this work or be a suitable bond? I also want to make pieces from scrap cutlery forks spoons kettles etc Ive looked up online and I've seen people are using mig welders for this. Has anyone tried this technique? And if so how well has it worked? Sorry for all the questions I'm just trying to figure out best way forward with your help and experience in the field. Thanks for the continued help giys -

Found these two at our local flea market on saturday. £7 for the pair a bargain I couldn't leave behind. Wife on the other hand not too impressed but I see diamonds in the rough where she sees rusty old metal haha and I cannot leave a good bit of crafted steel hanging around. Or steel that has untapped potential for future uses and projects for that matter either. After a bit of a clean up and they are looking much better. Now I have to decide now on the finish or paint. Your thoughts? span widget

-

Hi all i am a hobbyist blacksmith / sheet metal worker and i mostly do small decorative items for households and gardens, gifts for friends and family etc. i was until recently a car mechanic by trade with MIG and ARC welding experience. Its a little off topic and not so much blacksmithing as sheet metal work. My old mig welder died and i am looking to replace with either a MIG or TIG welder, i work with sheet metal no thicker than 5mm and would like to expand from steel into copper and stainless. do you think it would be worth purchasing a TIG welder over MIG. it would be a whole new learning process but i am not one to shy away from a challenge. I would interested to hear your thoughts and recommendations and experiences guys thanks a lot sorry posted in wrong section now ive added to the welding section of this site apologies

-

Help needed movable shop equipment

hobb0042 replied to hobb0042's topic in Building, Designing a Shop

thanks for the suggestions, i dont need to forklift anything ive got metalcraft XL workshop tools that i had mounted to stands that i need to drag out and put back when done so looking a temporary hold downs in the shop cheers -

Hi all so i've recently acquired a small workshop that im using for my woodworking cnc business ive set aside a small corner of the workshop front to setup my blacksmithing "hobby" that i would like to progress further into a viable add on business. ive got a good 25ft x 20ft empty work area in the day which i need to keep clear at night to store my business van. So ive managed to install my 3phase power hammer in a corner and i plan on making my equipment movable into the empty space and stored away at night. my question is what is the best way to do this? ive thought of drilling anchored threaded bars into various areas the floor that is raised enough for me to move the equipment onto and bolt down securely and remove, but is there something else i could do? would appreciate any feedback and thoughts thanks Mike

-

Made these small items what's the best finish?

hobb0042 replied to hobb0042's topic in Finishes for Metal

Thanks daswulf that's great to know Hey Glenn that I beam idea sounds real good thanks -

Made these small items what's the best finish?

hobb0042 replied to hobb0042's topic in Finishes for Metal

Thanks for the suggestions guys really helps I shall look into it more. On another note I want to make a sheet metal piece of art soft of life a portrait and was wondering if anybody has had good results with acid etching as a finish thanks for your help and suggestions guys -

Made these small items what's the best finish?

hobb0042 replied to hobb0042's topic in Finishes for Metal

Thanks for the suggestion Glenn -

Hi all I'm completely new to metalworking and blacksmithing I've made a few small timings in my spare time, anyway I found an old scrap length of 7mm thick rusted steel along my travels and decided to make some heart based items from it - No forging on this project just plasma cutter and a good old stick welder - They're patina is pretty good I like the well worn look but ive been struggling with the overall finish and look of them I tried applying an oil stain whilst they were hot didn't like it and then a standard black paint finish but was wondering if there was something better I could do to make the details of the patina stand out. The material was a dark rusted red colour to begin with. Any help would be appreciated thanks guys

-

loving the comments guys especially Frosty - "People who are laughing pay closer attention and remember better" hilarious and absolutely true. Yes i've no interest in making swords or knives axes just decorative pieces people can enjoy and sell well. im hoping for , key rings, bottle openers, etc for small start ups and sales work a few markets maybe etsy - (has anybody had much expierence with etsy? if you have let me know thanks) - and with some work and a lot of help looking through forums move on to candle holders kitchenwares such as pot holders, racking etc. Rose and all types of flowers i really enjoy making and researching other peoples methods and they are always a hit with the wife so win win haha you know when you walk in some place and there's a really poorly built put together something or other and your other half wants to buy it and your saying to yourself i can do better than that - that's where i want to be. and yes shes still waiting for the fruit and veg racking, the scroll shelf brackets etc i promised three months ago lol. luckily enough shes understanding although it does come up from time to time thanks guys

-

Thanks a lot for the welcome guys I hope to learn a lot along the way. Yeah unfortunately some people don't seem to see the value or the possibilities in blacksmithing and the old equipment usually goes languishing somwhere unloved until its tossed for scrap. People I have spoken to call it a dead art or forgotten past time but we all know different and I'm out to prove it's alive and well like all of us who understand and love and live the life.

-

Hi all thought id introduce myself, im a 30 year old trained car mechanic from the Wales. I first started getting into metalwork design, projects and pieces about two years ago and having the experience of welding grinding etc has really helped me along the way to deciding i want to get into this more. I've mad a few small projects for family and friends and want to get better and work harder at this field and hopefully run a successful small business from my work and all your invaluable help and information. im really interested in making small personalised items for people home decor etc i'm not equipped or experienced at looking for large projects. Ive got a corner of my workshop im currently setting up after purchasing my first anvil, a 3 burner gas forge and a treadle type power hammer as well as a plasma cutter some hand tools which i really want to expand on either by making my own punches drifts formers swages etc or purchasing along the way as i find. I look forward to talking to you all and discussing our shared interests in blacksmithing thanks guys