-

Posts

970 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Donal Harris

-

What did you do in the shop today?

Donal Harris replied to Mark Ling's topic in Blacksmithing, General Discussion

Cool work, Donnie. Did you plan for it to look like a set of scales? Why no spikes for the candles? Most others I have seen seem to have them. -

Do you have a press or power hammer?

-

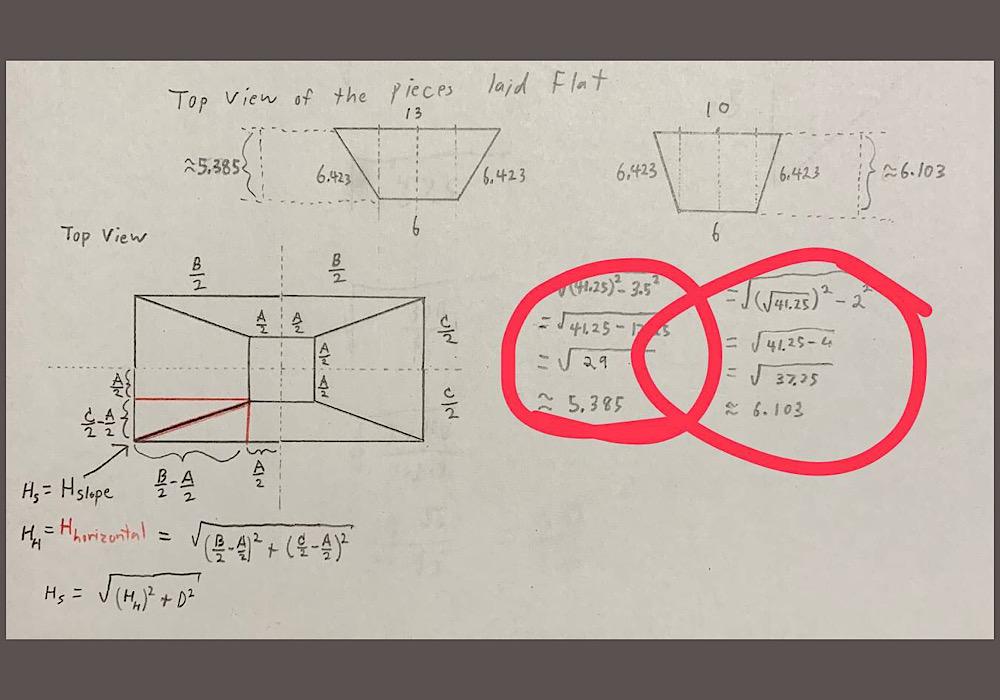

I’ve burned the heck out of my brake drum fire pot and have to build a new one. Does my math look right? I found several plans online, but most seemed to be metric and not inches. I can function with metric weights, temperature, mass, and volume, but not length. I want the pot to be 13” long and 10” wide at the top, with the bottom 6”x6”, and 5 inches deep. My tuyere is some sort of pipe with an external dimension of 4”. Not sure of the internal dimension of the pipe, but it looks to be at least 3/8”. The plate for the pot is rather thick, maybe 3/8” as well. I will weld 1/4” flat bar around the pot as a lip to hold it in the table. What do I plan to heat up in the forge? Like most, nothing much larger than 3/8”, but I do on occasion have to heat things up to 2”. An example of that would be a bale spike. Before I bought “The Undisputed King of All Anvils”, I took a bale spike, heated it up about 16” from the tip, and beat it to 90 degrees. I then cut it off and mounted it in a stump. It was what served as sort of a horn for me.

-

Spring Fuller (Or so I hope it will be)

Donal Harris replied to Donal Harris's topic in Tools, general discussion

It is half of a fish plate. I had thought I would make a guillotine tool from it. One of my FIL’s cronies owns a shop that makes box blades and such. He split it down the center with one of their very large plasma torches. After I had the plate split, I couldn’t quite figure out how to put both halves together as a functional tool. Thus the spring fuller in this thread and sort of a copy of a Smithing Magician which is on another thread here. Neither were quite as “magical” as I had hoped. All this began with the fish plate and a need to neck down drill pipe to make a few bells. I still haven’t finished the bells. (Or any of the other things truth be told.) -

I am what once was called a Medical Technologist, but is now known as Medical Laboratory Scientist. It is pretentious sounding and I hate it. NCA and ASCP merged a little over a decade ago. As part of the merger ASCP agreed to change the name to sort of match that of NCA’s. NCA certified techs were Clinical Lab Scientists (CLS). ASCP certified techs were Medical Technologists (MT). ASCP blended the two and came up with MLS for Medical Laboratory Scientist. Another concession they made to NCA was to begin requiring continuing education. New grads who sit for the exam are able to put MLS(ASCP) plus a little CM as a superscript at the end for Certification Maintenance. Those like me can do the same if we agree to pay the ASCP a bit extra each year and send our continuing education hours to them each year. Most of us do not. I was certified an MT and will die an MT. All of us are required by the labs we work in to turn in so many hours anyway. Going through more hassle and expense just to have credentials I never wanted seems a bit pointless to me. I have known several CF or COPD patients with it in their lungs. At first they would go quite a while between inpatient stays, but in every case the time between stays would become less and less. Not all strains are multi-drug resistant, but those which you pick up while inside the hospital often are, as you would expect. After all they have been “sent to school” so to speak. It isn’t important, but I believe you may be thinking of CDiff. Although I expect using antibiotics to kill Pseudomonas could very likely lead to pseudomembranous colitis. We all have to track and report CDiff cases now. It is a measure of hospital quality.

-

Why the switch?

-

Help with bituminous coal forge fire maintenance

Donal Harris replied to ZBarrett's topic in Solid Fuel Forges

It is restricted. Says I must have something called a G Suite account? But I was able to view it buy searching in YouTube itself. I’ve always thought that thing was a shovel, because that is what people I’ve seen using it appeared to be doing. I usually just use either my rake or poker to move coal or coke around. It looks easy to make one and did a much better job than my primitive looking rake. (My rake looks something like the thing they use in casinos to rake in dice.) And having seen his video, I will drill my holes to fit the rods I have available instead of drilling a hole and then trying to forge the rods to fit the hole. -

I can’t remember the site. They have a safety section with exactly two posts in it if I recall correctly. One is by a guy who is talking about the dangers of this sort of thing. He even posted photos of the bruises to his head and face that resulted when the piece he was working on was grabbed by the brush and wrapped around his head. He lost months of forging time due to the accident. The second post in the section was written posthumously about him after he tried to burn the zinc off galvanized pipe by placing it in his forge. He was very experienced and no one is completely sure why he tried to do something like that inside his shop. I didn’t intend to hijack this thread with safety stuff, but it is a very, very important thing. Even more so perhaps because most or at least many of us do not have a background in manufacturing or fabrication. As for the OP, very good find. The screw not being original doesn’t make it any less cool, especially at the price you paid. Those who have said a vice is the most important piece of equipment are right, which I expect you have discovered yourself by now if you have mounted and begun to use it.

-

Help with bituminous coal forge fire maintenance

Donal Harris replied to ZBarrett's topic in Solid Fuel Forges

Pardon the newb question, but what the heck is a “slice”? -

“Red clay” = Just about any soil in Oklahoma except in the eastern parts.

-

It is redundant to say, but Frosty is certainly right about the dangers associated with using a powered wire brush. When cleaning my vice after bringing it home I ended up wishing I had been wearing a leather apron. Those bristles may as well been needles as easily as they buried themselves in my abdomen and thighs. If you go without PPE normally, you will not want to do so when using a wire cup brush. The worst part happened after I had been using the brush for an hour or so. I got careless and caught my left hand with the brush when it kicked back. That hurt so badly I couldn’t look at my hand for a bit. I was sure I was going to see a broken, mangled mess.

-

I’ve never seen it pink, but then I’ve never seen it on media without nutrients. Usually it produces a greenish pigment. It is a nasty bug though. It is a rather common cause of nosocomial infections. It is also commonly the ultimate cause of death for those with COPD, Cystic Fibrosis, or must be on long term ventilation. It is very difficult to get rid of. Sometimes the colonies will have a very gummy texture because the organism is encapsulated. Horrible bug.

-

Spring Fuller (Or so I hope it will be)

Donal Harris replied to Donal Harris's topic in Tools, general discussion

Shoeshine the contact surfaces? -

Old microwaves have two very powerful magnets inside. Just be careful you don’t touch the capacitor unless you first drain it. I am not sure if the shock would kill, but it would hit you pretty hard. Another concern is the magnetron. Some contain beryllium oxide which is a carcinogen. Do not break the ceramic center of the magnetron.

-

San Mai blades. Hawks and such.

-

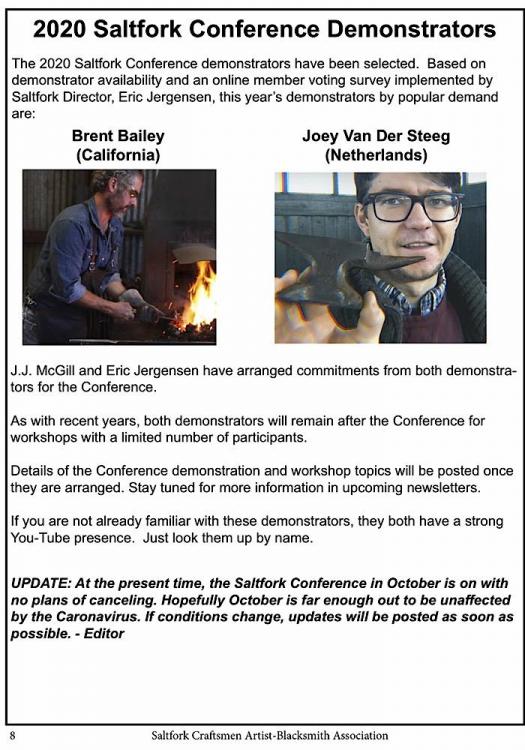

Assuming it doesn’t get cancelled, this year’s Conference will be October 17. I’ve been intending to go for the past three years, but something always comes up. Not this year. Nothing could keep me away (except COVID-19). I am hoping it will not be cancelled as all other meetings have been since this bug popped up. The demonstrators this year are: Brent Bailey (who is from California and not Texas as I had wrongly assumed) and Joey Van Der Steeg from the Netherlands. I am sure pretty much everyone here knows who they are. I am looking forward to seeing them in person.

-

He shot himself about 12 years ago. He lived with it for about a decade.

-

My baby brother had schizophrenia. There really wasn’t a lot of decent help. Still isn’t. Plus people don’t really understand mental illness. If you have cancer, people are sympathetic. Someone with schizophrenia is just avoided and whispered about. Someone with major depression, same thing except normally people aren’t afraid of them. They are full of helpful advice for them as well. “Just get happy” is a common thing they say. I will be praying for you both.

-

I thought Vulcans were cast? Are you thinking of Arm & Hammer? Both had a similar logo, but being cast, the Vulcan logo was raised and the Arm & Hammer logo was not. They are great anvils, just not nearly as common as HB, PW, and Mouse Holes.

-

Not only that, they are a pain to remove when you want to move the anvil to another base at some time in the future. I had to use an angle grinder to cut the heads off.

-

Material to line tire rim charcoal forge

Donal Harris replied to Phoenix Action Films's topic in Solid Fuel Forges

Orthographically? Sometimes I think you people just make up words of your own. -

Material to line tire rim charcoal forge

Donal Harris replied to Phoenix Action Films's topic in Solid Fuel Forges

“Worsens”? -

It won’t go on the wall. I plan to sit it in the corner by my sink. i had considered oak, but it seems a bit plain. i have plenty of copper sheet. I had considered forming the copper over the oak. I may do Osage Orange. I have plenty of that. And I have an old Delta bandsaw to cut the hearts 3/4 inch plate was just because it was what I have. But I was concerned about my ability to cut it into hearts. i have no stainless, so mild steel it will need to be. How can I connect the straps to the wooden hearts and still have the copper riveted look I was wanting?

-

I am wanting to reproduce this in steel. The slats from 3/4” x 1/8” flat bar. The shelves from 3/4” steel cut as valentines. I am thinking of connecting the slats to the shelves using blind copper rivets. The shelves will not need to hold anything weighty. Just personal hygiene items, tooth brush, razor, beard cream, manly moisturizing items, brush and beard comb. Perhaps a small copper bowl for pocket change and keys. Will copper rivets hold? I forgot, it is 24” high