-

Posts

970 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Donal Harris

-

-

On 12/4/2022 at 10:37 PM, JHCC said:

A stylized yarn ball to go atop a new sign for my wife’s yarn shop:

How do you clean up the welds inside the corners? I have been wanting to buy a die grinder for that and fixing wonky hammer eyes, but those which aren’t air tools seem like they would be too bulky to use. Dremel carbide bits do the job, but are really too small for it.

On 12/5/2022 at 10:44 PM, Daswulf said:Finished this guy.

Psycho jack.

Have you considered making a small axe to put in his hands?

-

-

My daughter wants me to make her something she says is a wahintke. I don’t have access to elk antlers and deer antlers would be too small. I figure I will use bois d’arc instead, because it is almost like a weed around here.

I figure I will bevel the blade as it is in the attached photo. Is the edge sharp at all?

-

On 11/29/2022 at 5:31 AM, lary said:

In Oregon you can salvage roadkill, Elk/Deer. A permit has to be filled out within 24 hours of picking it up. Now that I think of it, haven't seen that many dead deer on the side of the road since the that law was past 2 years ago.

I am not sure I would want to do that. There may have been a reason the deer was hit. To date there have been no documented cases of transmission of Chronic Wasting Disease from deer to humans, but no documented cases doesn’t mean it cannot happen.

My Precious came in today!!!!

I ordered it without a handle because I want to make my own from bois d’arc and I wanted to rust blue the head. If it already had a handle, I would have had to cut it off prior to that. Brent told me he usually tries to discourage people trying to make their own handles, because his head are drifted to fit his handles. I probably should have listened. It appears to have been blued already.

It is almost too pretty to use.

-

On 11/28/2022 at 10:32 AM, Daswulf said:

Hospitals are no fun but it is better to spend some time in one than a long time in a box.

In addition to being no fun, they are incredibly dangerous places to be. If you are not sick when you get there, odds are pretty good you will be before you leave. Your odds are improved by watching them to see if they wash their hands and be sure they check to make sure you are who they think you are before they draw your blood, give you a medication, or perform a procedure. Also make sure the surgeon knows why they are cutting, where they are cutting, and especially which body part is to be removed.

-

That was a board I had found. If I understand what I read correctly, he can switch to one of the standard guns, but will lose the ability to make adjustments for some things on the fly that he used to do with the guns microswitches. I’m taking the pictures by the local welding supply place sometime this week to ask them if they can tell me anything about it.

-

15 minutes ago, bluerooster said:

I've been thinking about making a cone mandrel that fits the Hardy hole for stuff like that.

Rather than a cone mandrel, I made a bickern? from a jackhammer bit.

And all those 16ths and 32nds reminded me of modifications I helped my dad make to his smoker over Thanksgiving. He made a math error and we cut a piece of pipe a half inch short. Had he not been using Freedom Units, it was probably one he wouldn’t have made. When working at home I’ve been toying with moving to metric. I saw in one of Jennifer’s videos where she was using a tape that was marked with both. I ran across one in late October and have been using it. Makes the math a bit easier.

-

It was punched and drifted. I made both the drift and the punch at the workshop. The little small punch I made from a piece of tie rod is not it. That picture was taken a couple of months ago to show what boiling does to rusty tools. The small drift beside it is the one I used. It was too small though. It was only used for the first two passes. To finish I had to use one of the other student’s which was fatter. I used a power hammer to punch the hole, but we drifted it by hand.

I don’t think you would be able to fill in the depression by forge welding a small piece to it. It would likely just get too thin.

-

9 hours ago, Goods said:

DHarris, I have a couple problems:

I see now. Your hatchet is something similar to what a good friend of mine refers to as a “30 footer” when talking about cars. Doesn’t look half bad when looking at it from 30 feet away, but when you get up close, you can see the rust spots, body filler, and orange peel in the paint.

I have made a total of of one camp axe and it was made from a section of thick leaf spring, meaning no forge welded bit. So this is just me guessing. You could chop it off and try again with new steel for the bit. But what I would do is cut the top off below the level of the crack. I don’t really like a lot of curve on the top of the head anyway. The area in the bottom circle I would fill by MIG welding. This should allow you to then finish the head into something which looks good and is functional. But you are right. You are going to need to grind a lot of it away.

This is a photo of my only axe to date. I can’t truthfully say I did it though. It is more an axe forged by Brent Bailey last year at a workshop after our club’s annual conference. I would say maybe 75% Brent and 25% me. The shape though is pretty close to being what I consider perfect. The top is basically flat. The toe does extend up a bit, but not much. The bit extends out beyond the toe and heel a little, but the curve isn’t pronounced. The ears are there, but aren’t overly large. My only real regret with it was where the beard meets the ears. That junction where they meet is not sexy at all. I don’t know if you’ve ever seen a real Brent Bailey axe or hatchet, but that is what I was shooting for: sexy, but not flashy. Sort of Mary Ann vs Ginger.

-

So, is that a Vevor with the area around the Pritchel hole built up? If so, how do you like it?

-

It looks OK, Goods. That is what grinders are for. No need to start over unless you are looking at something like this.

What don’t you like about what you’ve done?

This is my mallet. Made it from a bois d’arc limb a few years ago. Put a new handle in it at the end of this summer. The new handle wasn’t fitting well and rather than taking the time to do it right, I drove in a couple of shims along the sides. Wasn’t watching what I was doing and drove them in too far, splitting the top of the mallet. Thanks to Glenn’s advice on the other page about wooden mallets, I now know what to do to keep it from splitting further, or at least slow it down. Use a strip from a copper pipe around it.

-

My dad’s welder doesn’t get hot. A welder repair shop told him it is the gun. I’ve searched online for replacements, but none of them have the same pin arrangement. They all have the same pins as what is in the last photo. Even the online owner’s manual has pins like those in the bottom photo.

Has anyone any experience with guns for this welder?

-

I bought the Inventor series this morning at Tractor Supply. It didn’t occur to me to check and see if they are ANSI certified. They are. It didn’t occur to me to look for that. It should have since I am accustomed to looking up CLSI, ISO, and OSHA standards for lab quality and safety standards.

I saw they were ANSI Z87.1-2015 certified when Googling to learn the difference between 2, 3, or 4 arc sensors. Evidently when welding with the helmet awkward positions, it is possible for a lens to not darken. It seems 4 arc sensors makes that very unlikely to happen.

I almost waited too long to make a decision. The store I went to had only one Inventor helmet left, likely because it was on the very top shelf sitting behind some other helmets. It was the plain black one, but that actually suits him better then flames, skulls, or other such patterns.

Thanks.

-

I have two actual blowers. The first one is a Champion #40 that I bought when I first started. The second is a Canedy Otto Western Chief I bought a year ago at the auction they have at our annual conference. Both work fine, but I’ve just never hooked them up. I probably will soon, because my latest hair dryer is showing signs it is going to fail soon. I’ve gone through 4 or 5, but they are cheap at thrift stores. I never built any sort of valve or damper. The low setting was ok for normal forging and the high was ok for when I wanted to weld something. Reaching down to the switch was/is a pain, but to turn it on and off I mounted a switch to the bottom of my forge table.

It wasn’t until I began using charcoal to light the coke that I noticed I really have little control over how much air I am putting in the fire. What I want is an electric blower, but I never see them for sale. (Probably because TwistedHollow finds all of those for sale in Oklahoma and buys them.

)

)

As for flammable liquids, I would never use straight gasoline. Or rather not again. I tried mixing diesel with gasoline, but never could get the right mix. I may as well have been trying to light water. The gas/oil mix for seemed to be perfect and I already had it around for the weed eater. It seems to light and the flame spreads slowly. Much slower than lighter fluid one might use in a charcoal grill.

-

My Dad had a Lincoln auto-darkening helmet he used for many years that finally died. It was in just the right spot for a leak in the barn to fill it with water.

His Lincoln was on the lower end of what a professional would use. I wish I knew the model, but don’t. Since I do not, my question is probably impossible to answer, but I will try anyway. Are the Hobart Inventor or Creator series helmets good enough for an old guy puttering about in a barn? I don’t want to buy him something which could fail to darken quickly enough or is just generally unreliable.

-

Jobtiel, that scarf rack looks great, but I am more impressed with the screwdriver bit.

I’ve done the copper pipe thing for my vise jaws. In addition to not marring the what I am working on, it seems to be hold better. I assume this is because it is so soft. I believe someone here told me about the trick maybe two or three years ago.

-

I was pretty sure that wouldn’t fly. But no sentence is complete without at least one or two. I could barely speak when my Mom was around for at least a year or so after Basic.

I was pretty sure that wouldn’t fly. But no sentence is complete without at least one or two. I could barely speak when my Mom was around for at least a year or so after Basic.

-

[edit}

”He/she is squared away”

I no longer refer to my hat as a cover, but I still feel odd if wearing one inside or not wearing one outside.

I still inhale my food and surprisingly the mess hall is what I miss most. Best breakfasts I’ve ever had.

-

Was trying a wheat twist for the first time today. I probably should’ve tried with mild steel instead of wrought iron.

I wouldn’t have had nearly as much trouble fighting cracks and splits, having to do one side all over again because I made two left sides because I forgot to reverse the way I was turning the tool wouldn’t have been as painful.

Another thing I plan to do is go back to a glove on my hammer hand. Had I been wearing a glove I wouldn’t have been burned by the random bit of flaming scale.

-

When using bituminous, I used to put a few bits of coke from the previous fire on the bottom, followed by tightly crumpled newspaper. Over the top of that I would build a “cabin” out of kindling which had been boiled in wax. Around the outside I would place green coal and leftover coke. Once that was lit, I would slowly put on green coal but by bit.

For a while I really liked the ritual, but now I just have to get the fire going as quickly as possible. I get maybe an hour or hour and a half a few days after work. I just have to get the fire going as fast as possible. Newspaper,a few pieces of charcoal, a little slosh of weed eater fuel. Lights easily and fast.

This evening I tried putting the hairdryer on the lowest setting, that seemed to do the trick. Still sparked, but much less. Thanks

-

I’ve found it to be much easier and more reliable to use a couple of pieces of lump charcoal to get a coke fire going, but the sparks are terrible. Any way of using charcoal to start the fire without all the sparks?

It is a pretty show at dusk, but I get burns on my hands and wrists from them, plus a few going down my shirt.

-

Wonderful railings!

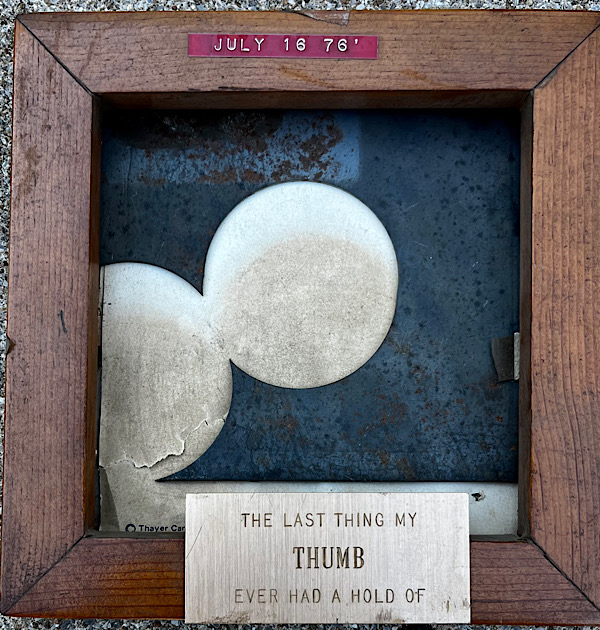

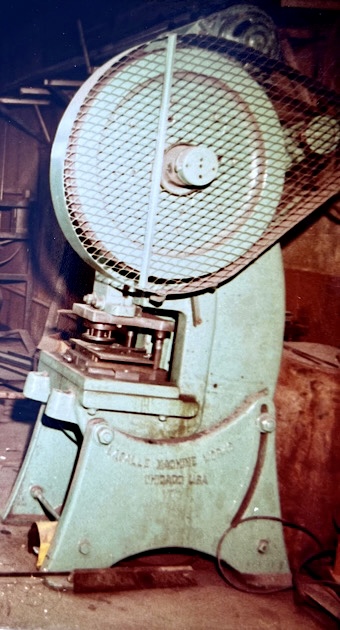

I forget the thread where I talked about it, but that steel in the frame is the last thing my father-in-law’s thumb ever touched. His joker of a nephew was the one who took the piece out of the scrap bin and had it framed for him. Below that is the punch die that took it off.

This morning I did a prototype for a thin slot punch to put a slit in pieces of old wagon tires. If it works I will make a better one. The small piece of leaf spring I used had a crack in it in the where the bolt passed through to hold the spring bundle together. I don’t think it should affect my experiment.

I have a slot punch that I used to punch the hole in the wagon tire I used to make the raven’s head cane. It worked ok, but I am thinking a wider slit would allow me to drift the slit for a hatchet or axe eye without having to stretch the sides too thin.

Before I try to use the punch, I will heat the struck end and try to upset it till it is maybe twice as thick as it is now.

-

-

And much more durable than jewelry pliers. I broke my wife’s pliers twice before I learned should probably get a pair of my own and definitely stop using them on stuff too large for them to handle. I tried blaming it on the grandkids, but she didn’t buy it.

What did you do in the shop today?

in Blacksmithing, General Discussion

Posted

Thomas, I don’t know what to say except we are praying for you.