Les L

Members-

Posts

855 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Les L

-

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

DHarris, you’re more than welcome to copy the angel. I don’t have the imagination that most of the people on here have and copy their ideas all the time. Your right about the dog, he was letting me know it was his supper time and I wasn’t paying attention to him. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Das, thanks it’s steel with a copper sulfate finish -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Dharris, the tree and knife look great. Das, your imagination never ceases to amaze me. Made my wife a figurine to add to her decorations yesterday. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Great job Das -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Das, the copper wire will work harden when worked cold, heat it and dip in water to soften it again if you need to work it cold. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Das, Great job on the cross -

Amazing, as always.

-

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Billy, I agree with Frosty that it’s a good looking piece, but needs a little more work on the holder and plate to really bring it over the top. Frosty, I’ve got all my wood stacked at the house also, about 40 pieces that we’ll use sitting around the fire pit roasting weenies and marsh mellows with the grandson, but we have several cords cut and stacked at the hunting camp ready to sit around the fire and tell stories. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Yes, I figured that out years ago, I just try to keep my head above the water, keep the list short, and the heat in the forge instead of on me. I’m not afraid to tell them tomorrow hasn’t got here yet. Frosty, thanks to you and all others for advice on mounting anvils. My tripod stand and mounting it with silicone has brought my soderfors to a quite thump, except for a slight ring from the horn and heel, I haven’t worked on either yet to see how loud, but the main body is quite. Das, I think we’re in the same boat! You think our wives are sisters, and didn’t tell us, or maybe it is just a common trait? -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Das, I think we all have it in common, but that’s why we love them. This morning I was asked what I was going to do today, I said going fire up the forge and make the items you requested, went out to the shop at 8:30, 1 1/2 hr later my phone was ringing with “ I need “ , 2:50 finished with today’s list. Needless to say I didn’t get much done, but did get to test the new anvil, and stand, which was the main goal. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Das, that’s great advice and thanks for your concern, I’ve been a certified welder for the last 45 years, so I’m not worried about it falling apart during the testing period. I worked with it some this morning and am happy with it so I plan to finish it tomorrow, if someone else doesn’t come up with too long of a list of “I needs” for me. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

I got started on the stand for my new anvil yesterday. Didn't have time to finish and install the leg braces with shelf, had to stop and make a gumbo for the wife, but I think I'm going to use it some as is in case I need to make adjustments to the height or the angle of the legs before I add it and the base plates. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Buzzkill, have you been sneaking around in my shop while I’m distracted with my work? I thought it was me, but I’m having second thoughts now. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Billy, I like your knife and bracket. Great job on both -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Great looking dragon -

Thanks Frosty and TW, I’ve been searching the web all morning and I’m thinking Soderfors also. Frosty, I’ve read about your love of them so I’m going to put it to the test as soon as I have time to build my tripod stand for it. I definitely noticed the ring when I dropped a ball bearing on it, much more than my Mouse Hole. The edges aren’t chipped, someone used it while cutting with a torch and gouged it in a few places, but not enough to complain, especially when I got it for $500

-

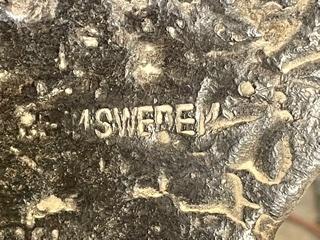

I went to our blacksmith club meeting yesterday and this followed me home. It's stamped 211#, but my two scales each weighed it at 230#. It has 85-90% rebound across the face. I can see it's made in Sweden, but if anyone knows who the maker was I'd appreciate the info. Thanks.

-

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Pat, I cut them with a diamond masonry wheel on my 41/2 inch grinder. I have a cheap one, about $8, and it cuts them like butter. Wear a mask and face shield when doing it. -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Pat, great job on the rose -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Pat, I arc weld my leaves on -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

John, you’re heading in the right direction working it out on paper first, I’m waiting to see the finished project -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Lary, when you put it on, I use a chip brush, the color is there no waiting time needed. Depending on the project I’ll leave scale on purpose, or I can’t clean it 100% like the roses, to add details. I haven’t tried the electroplating, like Frosty described, but it’s on my list -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Jennifer, more information on the knife please -

What did you do in the shop today?

Les L replied to Mark Ling's topic in Blacksmithing, General Discussion

Lary, I use copper sulfate on several of my projects. I just wire brush the project when I finish forging and apply the copper sulfate mixed in water. it will not stick to areas where scale is left, but sticks to the clean areas with no problem. I wash it in hot water after applying, let it dry and brush it with a stainless brush to achieve the finish I want. -

That should be pipe thread (tapered) I would guess 1/8 or 1/4 NPT. I would just get a plug and put it in the hole. I would take and warm up the area around the broken off piece then spray with penetrating oil, giving it time to cool and penetrate, do it a couple times then try to back it out.the cast iron should be good, you may need to dress the threads, but I doubt it. I’ve taken a torch and blown steel bolts out of cast housings without hurting the threads. JHCC, those look similar to the elevator rail brushes I use a lot, I think you will enjoy them.