-

Posts

290 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by HojPoj

-

Even though I don't have them out at the airfield where I work, when I host contractors for meetings and they ask me about dress code I usually say business casual (and then they show up in ties). I've taken to telling them that I will be very angry if I see any ties- what some fail to recognize is that there's the threat of getting choke-slammed by the tie.

-

Thanks for this continuous output of material, Joe! It has been quite informative and entertaining to follow along.

-

Latticino, most computer muffin fans top out at 200-500 mA at twelve volts, so the fan in question should conceivably push more than a computer fan. As for the fan's performance, even as a shrouded axial fan it's unlikely to develop sufficient static pressure to do the job reliably. Also note that it's probably louder than you'd expect.

-

A collection of improvised anvils

HojPoj replied to Charles R. Stevens's topic in Anvils, Swage Blocks, and Mandrels

At the heaviest that'd be 257.51754 lbs. (884.9ish cubic inches multiplied by a density of 0.291 lbs/in^3, though the density is cited as somewhere between 0.28 and 0.291) -

What did you do in the shop today?

HojPoj replied to Mark Ling's topic in Blacksmithing, General Discussion

Aesthetics aside, that last part's the most important. The second question is "Do they work well enough for your needs?" If yes, then Bravo! Heck all that work you've done is more than I've accomplished in my attempts at making tongs. I've yet to do some from scratch that have been worth finishing. -

Not sure how trash collection occurs in your area. Around here there's bulk pickup weeks where such stuff is put to the curb for the claw truck to come by and pick it up. Those would be the opportunities while doing 'necessary' errands ;-) As for the capacitor, I've not come across one that DIDN'T have a bleed resistor on it (something like 1MegaOhm). by the time someone goes to throw an old microwave out it should have done its job and discharged the cap. As with most high power electronics, have a pair of rubber gloves and a sacrificial screwdriver handy to be sure the job's done all the way. Thanks for the heads up on that ceramic- I was unaware of its composition.

-

Also look for old microwaves being sent to the tip, when the magnetron is disassembled you get a couple of decent ring magnets- I've amassed a few over time and they certainly help on my small anvil.

-

Well, I can say the 28th edition doesn't have anything in the index for Blacksmithing, Forging, Forming, or Tongs.

-

What John said, mostly a concern that they might not like being forged if they are, in fact, a leaded steel. Only one good way to find out! I hope you're lucky and they're something way more useful :-)

-

Not sure if it was cautioned before, but they might be 12L14. I know you'd mentioned they had some end drilling/machining done before, but in fairly low stress applications it tends to be favored for the ease of machining (or deep hole drilling). I know most of the bars of it I have are either square or hex. Guess you'll find out when you start to forge it.

-

What did you do in the shop today?

HojPoj replied to Mark Ling's topic in Blacksmithing, General Discussion

Glenn, yeah I was going to fatten up the top of the ring, probably use some hose. However, busting a knuckle is incentive to pay closer attention! -

What did you do in the shop today?

HojPoj replied to Mark Ling's topic in Blacksmithing, General Discussion

Not much smithing aside from cold-bending the ring and flattening the mower blade, but I fabricobbled up a small kindling splitter so my Kindergartner can help her daddy 'chop wood'. Just need to screw the feet down to some chunks of 2x4 to raise it up, but it's suprisingly stable as-is. -

The stuff you've listed is why I've been hunting for 'em, JHCC. It would figure I finally get these after buying a few feet of 1.25" Hex 1045.

-

After some back-and-forth I finally met the owner of an equipment rental place and made off with some of their unusable breaker bits. If I had the time and skills I'd look at sharpening some and see what he'd be willing to pay for re-pointing the worn ones he has (the heat treating requirement is what keeps me from looking into it further). Something like 18-20 bits here, I gave him $20 and a bottle opener.

-

What did you do in the shop today?

HojPoj replied to Mark Ling's topic in Blacksmithing, General Discussion

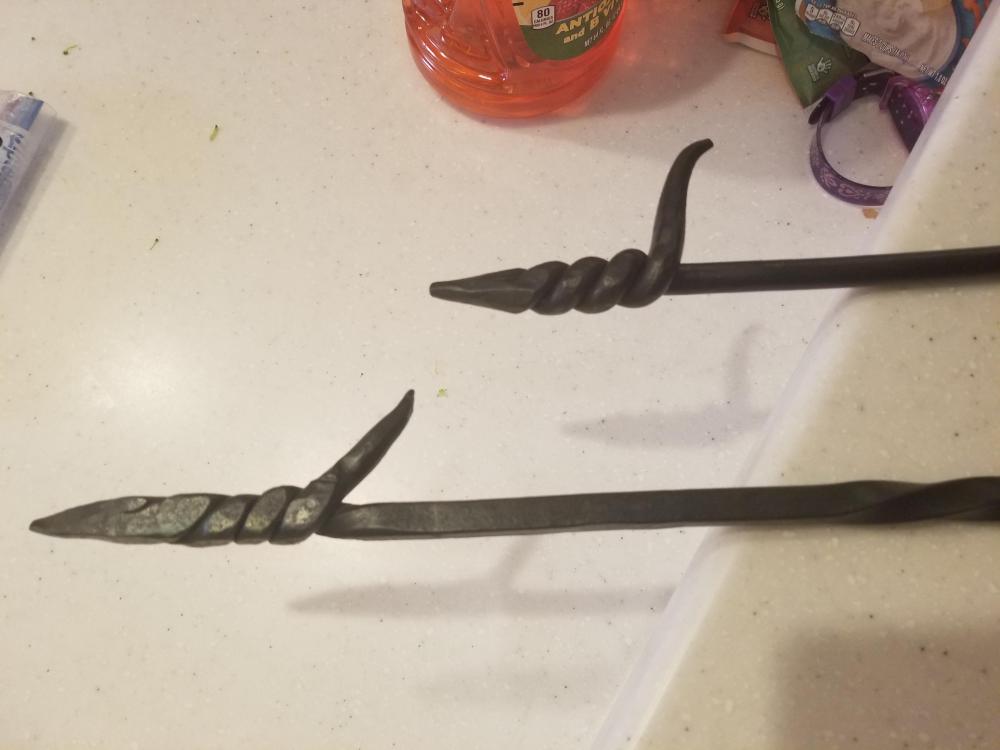

Got a few hours today in what seems like forever. Made a couple fire pokers because I needed one for my fire pit- was playing around with twisting the tip since forge welding isn't something I'm able to do at this point in time. Also made a couple bottle openers and hooks, though one isn't pictured since i gave it away. -

Recently found a 100 lb. Hunk of steel at the scrapyard. Will be far more manageable than the other giant hunk o stuff I have. The are two shallow 1/2" threaded holes in it that should aid in manipulating it for use on-end or on its side for striking. Forgot to measure it, though... d'oh!

-

acciaio anvils, still ok?

HojPoj replied to bertie_bassett's topic in Anvils, Swage Blocks, and Mandrels

That's where I do most of the work, I rounded off the corners there, and stay away from the rest in order to preserve the sharper corners for when I need 'em. -

acciaio anvils, still ok?

HojPoj replied to bertie_bassett's topic in Anvils, Swage Blocks, and Mandrels

For mine, my best guess is that they are induction hardened since the outer skin is hard, but dents fairly easily. -

Mine is a 66 lb version of what you have, I am aware of the space limitations. It may just be that your current ones are too stiff at the top, hence the suggestion to thin the arm out a bit. I made mine from something that was 5/8 inch Diameter for a 3/4 inch hole, and when it sticks I pick the anvil and stand up by it... it occasionally it doesn't stick and has to be smacked a few times before it works.

-

Though if you want to try and salvage what you have, I would suggest flattening the arm section (or draw it out a bit more) so that it's a bit more flexible, this may help create more of the side force necessary to hold it in place.

-

Oh definitely. I only say 'in theory' because after using it a few times it might get wedged in, or it might wallow the hole out too much to be useable. Just figured it was worth the experiment.

-

Haven't used the hot cut yet, but in theory it can come out.

-

It can be shortened, but the whole thing's pretty light so it wouldn't do much damage. I was in a hurry when I made it, so I wasn't thinking about the added length when tapering the material down... whoops.

-