-

Posts

89 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Zrognak

-

I use what I can get a hold of but I try to stay away from heavy hard woods for hammers and axes, I cant speak for other people but I found it is too hard on the hands to use that. So I tend to use the following Hickory for hammers and axes (Don't know if this is standard or not) Beech, Birch and Moose antler for Files, chisels, and a few other tools. Also use birch for carving knives. Hickory and beech i can buy pretty cheap in town, Moose antler I got a lot of and can get pretty easy as well as Birch I got a abundance of cause it grows everywhere.

-

Cool never heard of Simonds or Johnson files so thank you for sharing

-

Thank you, and don't be to hard on yourself im sure your leather work is good. Thank you sir. Yea scrap steel is not fun to work with at times, for example I forged a knife from a old truck spring and it ended up being cracked in multiple places, thought I had failed with the heat treat but took a closer look at the leaf spring it had a lot of micro fractures ones that didn't show up on cause of the rust. Lost time is not good if you are trying to make money, but as I see it im not selling anything im just working right now to get better at forging and fit and finish, so if I have to start over as much as it is frustrating the only thing I lose is the fuel I use for the forge, for me the time is not lost cause I learn a lot. But I hear ya man, as soon as I can afford to buy a good amount of good quality steel I will start using that instead cause I still need to learn how to heat treat certain steels and how to work them so it is a good idea. And thank you for your kind and encouraging words.

-

Thank you for sharing, I will definitely look these up, as for price i do not have a lot to spend but I would still pay for a good file. I would love to find some new files, think i just had bad luck with the new ones, but yea I found most of my files from auctions and such. Cool I never tried to remove rust on files with vinegar, doing it to some tool steel wire as we speak, but it is a good idea for files too ill try that next time, thx

-

Sorry missed this post yesterday, thank you and yes indeed it is neat, ill cherish this anvil for the rest of my life That is really cool, thanks for sharing.

-

That is really interesting, thanks for sharing.

-

I found getting a touchmark or signature was really hard for me took many years before I decided on a design, I sketched over 400 different designs before choosing one. I never made one before and I could not afford to pay someone to make one for me at the time so I had to give it a go myself, it is not a professional level but it will do for now, going to get a professional to make me a few different sizes for silver and for hot steel in the future but for now these will do and I been using em for about a year soon. they are pretty small. The symbol is supposed to be made from my initials SH, i don't know how well other people can see it or not know it might not make sense to some cause of the design i made but for me it is clear. So many cool designs in here, thank you all for sharing. Bless you all.

-

Greetings, I love files but I am mostly familiar with Swedish files, Öberg files being my favorite brand, they don't sell em anymore or at least not the same quality but I got a few I been using for years. So Im interested in hearing what kind of file brands people here on the forums use, im aware of Nicholson files but that is the only one i seen here and they are pretty good only got one so haven't gotten to test em much, so im curious what brands are used by other blacksmiths. I found it is hard to find good quality files these days, they are not bad but not the same quality as the old ones I been using, cause I had those for years and before that they where used by other people for years and they still cut great, compared to a new file that lasted only a few years while the old ones are going strong. I like to add I don't abuse my files, if it is one thing Im actually good at it is how to use a file, I like files if you already didn't know Also like to add this is not a promotion for any file companies, since the files im using Öber is no longer in production.

-

Im Swedish and I didn't know that, that is pretty cool.

-

-

What did you do in the shop today?

Zrognak replied to Mark Ling's topic in Blacksmithing, General Discussion

-

What did you do in the shop today?

Zrognak replied to Mark Ling's topic in Blacksmithing, General Discussion

Heat treated my small anvil today. Pardon my bad filming, hope it is not too messy. https://www.instagram.com/p/BmTldOGAfNV/?utm_source=ig_web_copy_link -

NoName that is Awezome, yea I heard of em, they made good anvils, never gotten my hands on one but I live in Sweden so it is just a matter of time, that one you got there is a nice weight 155kg real good weight, and it is really cool that one made it all the way to where you live, that is quite the trip for an anvil. Frosty indeed Sweden is a really small country, a long country but still small. Ill take some pictures when I go down to the forge later today.

-

What did you do in the shop today?

Zrognak replied to Mark Ling's topic in Blacksmithing, General Discussion

Irondragon forge & Clay and Frosty thank you that is good to hear, it is partially what I will be using it for so, as for polish that is a great idea i got it at 400g right now but im going to heat treat it so though I continue after it is treated. ThomasPowers that is cool, I found the rail near a house my mother and father owns, believe the house is around 120 years old or so, no idea how it got there there was a old barn there but it did not have any huge sliding doors could also be a rail they used for hanging up game and livestock for butchering , maybe the people that lived there ones brought it home to use for something, but that is cool did not know they used such small rails in mines good to know, either way it seems to be some type of steel, never been good in knowing these things by just doing tests, but the piece i tested to treat broke off cleanly and the grain structure was quite smooth actually, so we will see how hard it gets. Going to search the forums for info on heat treating similar things cause never done one of these before. Awezome stuff in this thread, always fun to look at talented peoples works, even if you are just cleaning the shop it is fun stuff it is good to see peoples workshops. Cheers! -

What did you do in the shop today?

Zrognak replied to Mark Ling's topic in Blacksmithing, General Discussion

Got invited to my brother for dinner but before I left I made a really small anvil or if it can be called that. It is made from some type of rail, dont know if it is a rail from a barn door or if its from some kind of lumber rail and don't know what type of steel it is, but it can be heat treated from the testing I did of smaller pieces from it so ill do that in the morning, im out of coke but I think i can scrape together some charcoal even though my lungs hate it will be wearing a dust filter. It is nothing fancy, I know some might wonder what it can even be used for cause it is so small with a thin neck, but I will use it for really small works, with my extremely tiny hammers. it is 64mm tall and 110cm long. going to make a hard wood base for it so it sits a bit more sturdy on the work bench. Hope everyone had a good day. Cheers! -

Could not have said that better myself, exactly what it needs

-

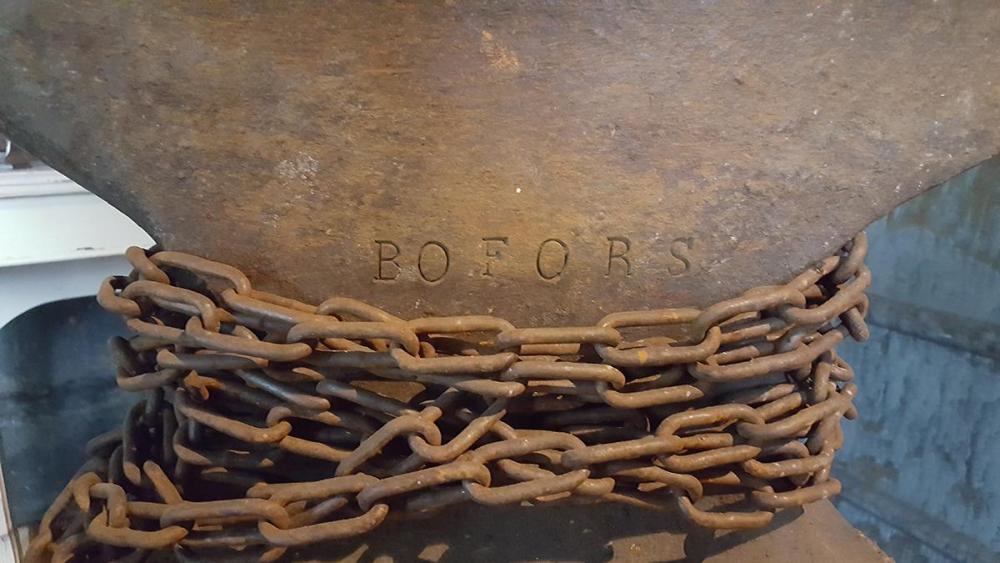

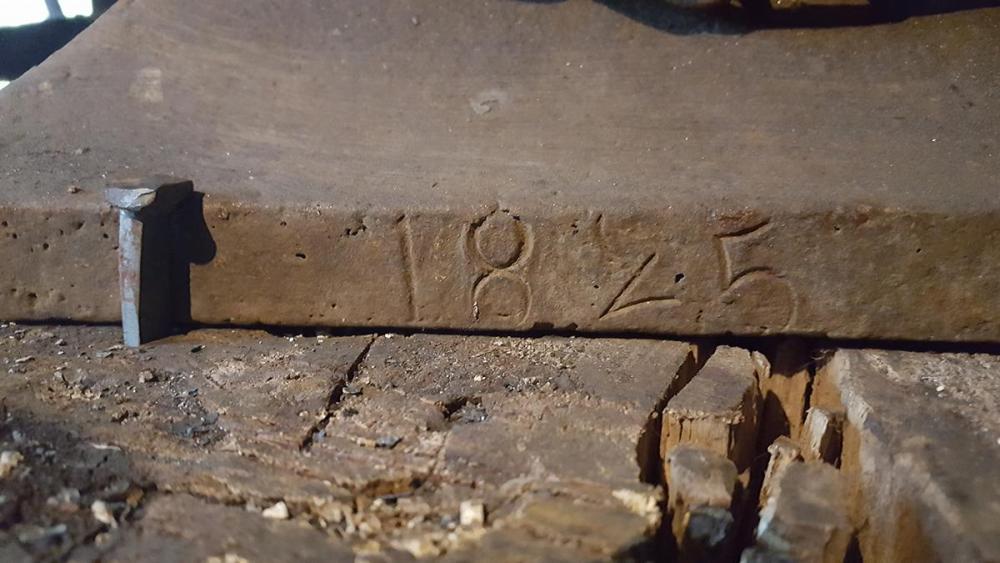

I got a old Bofors Anvil from 1835 that my ancestors worked on in a iron foundry or iron works is maybe the right word, I found on a site this guy close by was selling it for 2000kr which is around 200Usd like 12 years ago maybe, I got the whole story behind where it came from hes fathers father or father i don't remember exactly, but he bought it home after they closed back in 1892 i believe and I also found out we where related, as well as had more relatives working in the iron works at the time. it is a bit banged up, think someone been cold forging on it after it left the iron works for a few years reason it has chipping but could also be damages not caused by it being over 180 years old. The man i bought it from was around 70 or so, really strong guy, he lifted the anvil into our car by himself so fast I didn't have time to help him, compared to when I got home later it was tough for me to carry it into my smitty and on top of my birch stump not a problem for me but man it was felt heavy, but he lifted it like it was nothing, admire that kind of strength. I love my anvil, will cherish it for the rest of my life. It weighs 93kg (roughly 205 pounds) dont worry this is a old picture of it probably from when I bought it, it is secure now. Not going to try to renovate it i will leave as is.

-

Tools that pay the bills and feed the mouths...

Zrognak replied to templehound's topic in Folding Knives

Just realize this is a 1 year old thread, my bad. -

I start with 180g move to 400g then 800g then move to the polish wheel for a mirror finish if I want it to be polished that is, as for handles i sand with 180 then wet the handle with water so the fibers rise if im using wood that is then finish with 400g then use 0000 steel wool(not recommended for some wood types that have a lot of pores) I like to add im not a professional knife maker, just a amature so take what I type as possible suggestion, you chose your own way of doing things.

-

Tools that pay the bills and feed the mouths...

Zrognak replied to templehound's topic in Folding Knives

Not personally a fan of these types of handles, but it works well I dig it this time, the craftsmanship is really good, these should sell like butter. Could easy see myself buying one of these in the future. -

These are beautiful, question though about the burl and resin handle, will that handle hold up, I never worked with the material myself but I read that they can break where the resin meets the wood if they don't have a reinforced backing? not that you would use much force with these so it should be fine, just curious cause I have never worked with the material.

-

Wow, really interesting design, all of them are great works of art. Is that mokume-gane on one of em handles? It is good to see new ideas for folders, it is a unusual shape i never seen before good job!

-

Thank you sir that is kind of you to say. And yea personal preference on things we like can be so different, its a good thing though cause so much variety to look at, I been having a good time going through the forums, so many talented people, both who are new to blade making and veterans, so much great stuff. But anyone can speak their mind about what they think about my stuff even if it is a personal view, I never think there is such a thing as bad critique. And you are right it works pretty good as a utilitarian knife, I can have it on my belt and on a cord around my neck so it is a bonus.

-

Thank you, yea I did specially like point 2, think respecting ones elders is something that people lost these days.

-

Thank you, that is great feedback. Knife 01 took longer to make then the 2nd knife, here is a pic from the side. im happy with this knife from a functional standpoint cause it works great as a hunting knife. We are all different, it is great cause something has been bugging me about knife 02 and now I know its the guard in buffalo horn think the shape of it and the color of the horn does not fit at all now that i come to think of it, it is not the only thing though. as for the square handle that is a preference for me personally what it was going to be used for was going to be doing a lot of twisting motions with it and needed a firm grip, but yea it is more a art project than anything cause i never used it much, but it is good practice to get better. I like the rock pattern personally but it can be useless to have on some knives, like the knife I made cause it can scratch the wood if im not careful. I love all knives, if they have art or if they are simple, think it that sometimes knives though considered "simple" are masterful art pieces, and should be acknowledged as such, just like this forum has a great variety of blade makers so have a great variety of blades, think the world would be so boring if everyone made the same stuff. And the great thing is we learn from each other, like someone who is detail heavy can learn from someone who makes clean knives and vice versa, think balance is key. For personal preference, I seen so many knives with too much going on that it takes away from the over all craftsmanship, though greatly crafted think sometimes It can be a bit too much, so personally I would want to find a balance, cause Im not a blade smith right now but I might become one in the future, I would want to make artsy knives but I don't want all my stuff to sit on some shelf someplace, I want em to be used. Thank you again for your feedback, greatly appreciated.