DungeonX

-

Posts

24 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by DungeonX

-

-

It is my first hardy, actually my first tool. I have started with a 1" round bar 40" long of 1045. I have tapered it down to 3/4" to fit my anvil and it slides in to about 1.5 ".

The rod is too tall to upset on my anvil so I need to cut a piece off.

Q1. how much do I need above the shank?

3-4 inches or more?

-

-

-

Ok so this afternoon I ran the forge for an hour and hammered my first spike in to something resembling a knife shape(to me anyway). The forge ran well and the refractory actually was glowing a soft orange.

Q1. is that expected? I am assuming yes.

Q2. I am trying to draw out some length and width while battling the tendency to twist. Any advice?

I need to work on my grip strength cause after swinging the 2lb hammer for an hour I can barely type this message... haha

-

Ok I will look in on the kiln shelf. I couldn't wait I went back outside. It took less than 8 minutes and the spike was red hot.

-

ahhhhhh, haha yes I should have known that. Yes I do plan on doing that. I still have to learn how to weld

-

Ok I will move back the burners. What would be a better floor, I was thinking that using the brick would allow it to be replaced easily later. and I'm not sure what you mean by "You need angle on the forge face to use bricks to control heat loss."

-

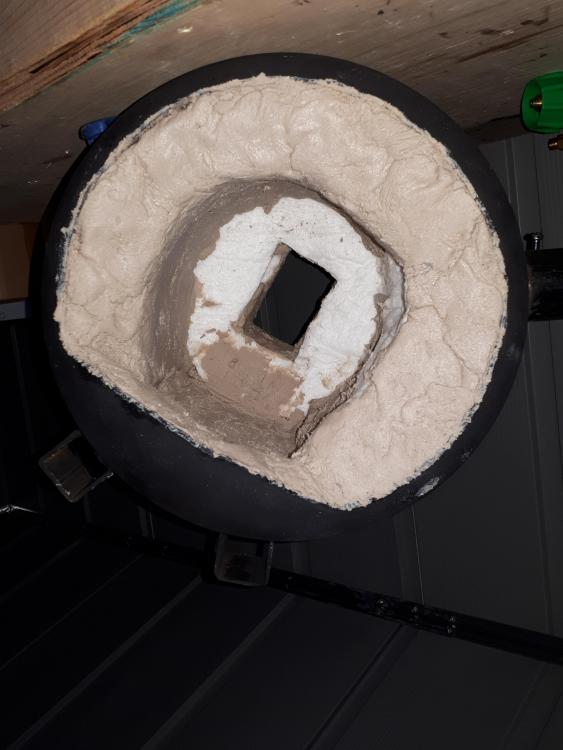

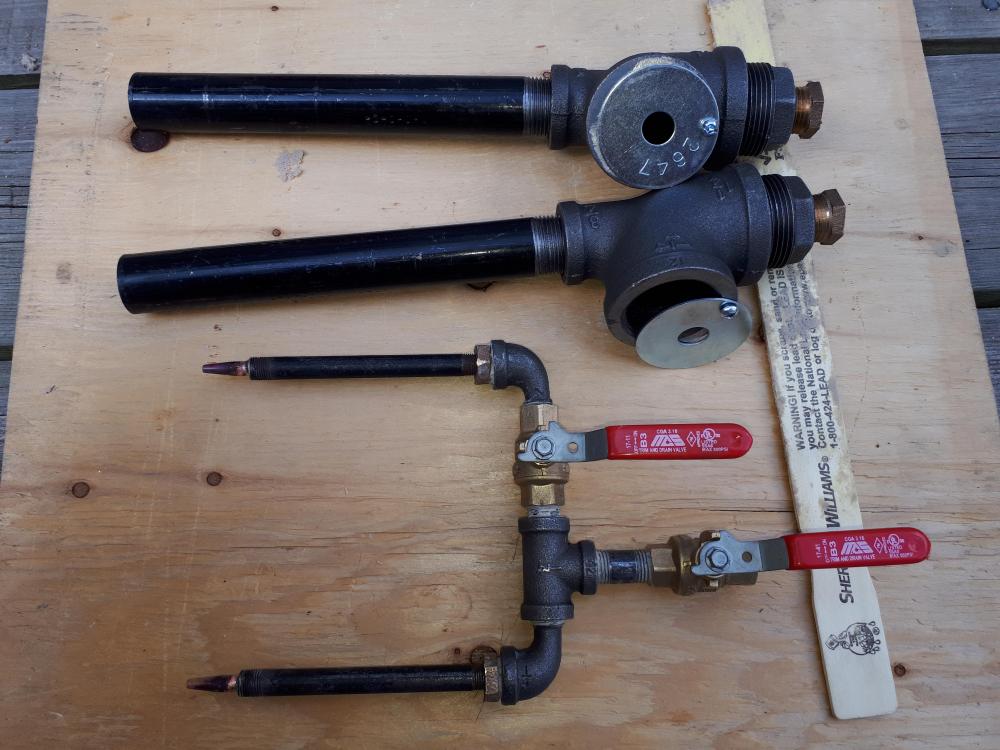

20# propane forge is operating Kaowool, refractory cement and plistix. double sidearm 3/4" burners with stainless flares. Good blue flame seems to jump out a good 2 or more inches.

Q1. How long should a single railroad spike take to heat up to forging temp? Avg.. just to have something to expect or compare too.

Q2. Should the stainless flares get red hot or does that mean I should get them pulled back a little more?

Q3. Flames run blue but have an occasional orange flame puff and then continue blue. Does this mean something else needs adjusting?

-

I am just going by what I was told by the man I bought it from. I am not really sure myself I will get some pictures of the identifying Mark's later.

-

-

no I wasnt saying that. I am just starting to try this as a hobby and would like to learn from someone. but I do have a job that has me on the road a lot and dont want to inconvenience a professional

-

looking to learn from any hobby Smith's near Peterborough Ontario

-

yes I found them at Bardon supplies

-

-

-

I have 14T mig tips but they are not "tweco" they have an "ms" stamp on them. I asked at the pipe cutting shop for 1/8" schedule 80 and I believe that's what they gave me. I was thinking about getting and end cap and drilling and tapping it to screw the mig tip in to.

-

Thank you for the help Frosty. I have gotten to a larger city and have been able to get 2 of the proper ward reducing tees, and I am ordering 2 SS Flares from Zoeller forge. My biggest problem now is that the 14t mig tips seem to be to small for the 1/8" black pipe. Any ideas for me?

-

my front end opening is 10" wide by 8" high and back is 3x5

-

-

Hi All,

I am new and from Ontario Canada. I just started gathering the pieces to construct my first burner for my 20lb propane tank forge. i got 14T mig tips but they seem like they will be too small for the 1/8" schedule 80 pipe and that's before threading. what should I do? I'm having trouble finding a 1.25" x 1.25" x .75" reducing tee. And I have red handle plumbing ball valves,can I use those or do I need to find gas ball valves .25". I will probably come up with more questions.

-

Hi All,

I am new as well. just started gathering the pieces to construct my first burner. i got 14T mig tips but they seem like they will be too small for the 1/8" schedule 80 pipe and that's before threading. what should I do?

My first hardy w/ pics

in Hot Cuts, Anvil devils, metal cutting on the anvil.

Posted

Ok so I cut it off at 5" and tried to upset it to create some shoulders which didnt really work for me. I flattened and flared out the service end which turned out alright. It wound up being a flat side hot cut rather than a peaked. I still need to clean it up.