paulgatx

Members-

Posts

71 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by paulgatx

-

I've been using the TPAAAT actively in the past week which as been fun. Hasn't turned anything up yet (yes, I know, 1 week is nothing), but this Mousehole did just pop up on CL. It's not a huge value at $4.26/lb ($550 for 129 lbs), but to be honest it's by far the cheapest decent quality anvil that I've seen recently in Central Texas. I haven't had a chance to see it and test it in person yet, but the sway in the picture was the first thing that struck my eye. It doesn't look crazy but it is noticeable. Also, there's the chip. Pritchel holes puts it > 1835 I think, but can't make out anything else from the picture of the stamp to tell anything more about it. Any thoughts without any other info beside the pix? Thanks in advance.

-

No worries, I do really appreciate the information and input from the experts. That's why I came here. And yes, I'll do the right thing. Out of curiosity, does anyone use SCBA? I couldn't imagine doing that while forging, but I'm surprised it isn't mentioned with the types of concerns raised about point-of-use CO generation. Thanks!

-

No, certainly not. But I have no data to say they are equivalent. I hear people saying it, so I am listening, but I'm also asking if anyone has data? Sorry, again, I'm an engineer so I let data speak for itself. If I have no data then certainly I will err on the side of caution.

-

MCHammer, thanks for the candid feedback. 1) re: insurance, good point. I will check on it. If it is a definite roadblock, then I will resign myself to the driveway or the back patio, which I didn't want to do because of two steps that I'll have to have ramps for to move the equipment around. Other than the summer heat, which can be dealt with, I'll have long periods of really good weather here in Austin (i.e., not much cold and/or rain). 2) Agreed, I hope you don't get the impression that I am any less careful with my family. I'm simply gathering the information now. There is risk in many things we do, and the key is a thorough risk assessment and mitigation strategy (can you tell I'm an engineer and project manager). 3) I have a vented attic directly above this area, so perhaps it would be easy to run a pipe up and out through the attic. BTW, do you know of any good studies on the amount of CO produced by these forges? It is mentioned so often in these discussions that there must be. I have a full-time 60hr week job that I will not be retiring from anytime soon, so this really will be an every other weekend type of hobby (for now) and I don't see a lot of continuous hours with the forge on. If I can calculate how much CO I will be producing in a session, that can help with the mitigation strategy. Cheers!

-

Thanks. Do you do anything special for ventilation for the CO? I'm wondering if the through-breeze with fan will be sufficient to move it out. Does anyone wear a respirator when forging? I know people do when grinding for the particulates, but I don't think I've seen anyone forging like that with a CO-proof respirator.

-

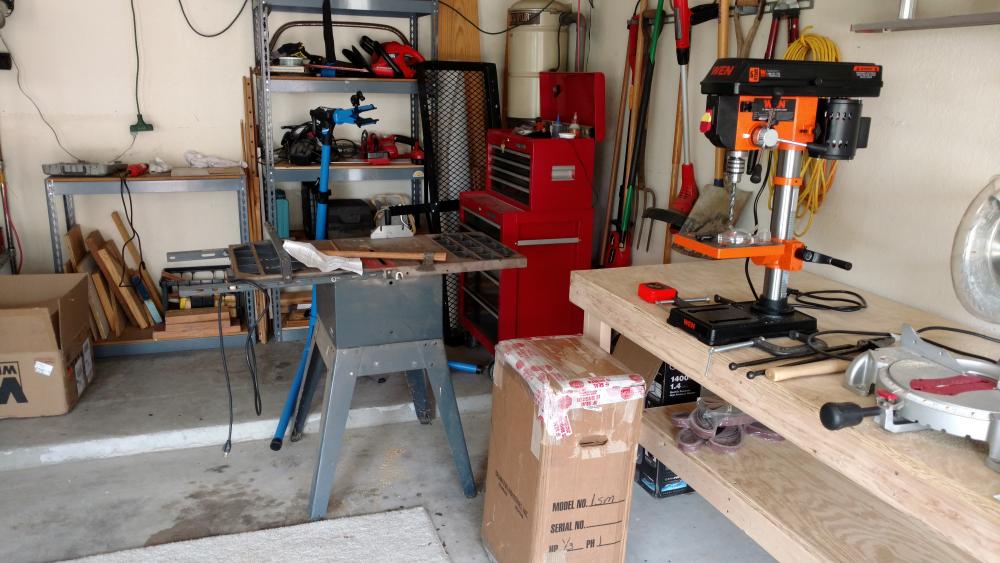

Hi all, new guy here. I'm planning on starting up my own small home hobby shop in my garage and I've been doing some research on this sight, but I wanted to get some more specific tips for my setup. I live in medium density suburbia (lots < 1 acre but not zero lot line). I have a 3 car garage and plan on setting up in the third bay furthest from the house as you can see from the pictures below. There is an attic directly above the workspace. I have small work benches and shelves in an L-shape against the back and right side of the garage for the various tooling. At first I'll likely set the forge (smallish 2-burner propane with 20lb tank) on top of the small table saw in the middle of the space in the picture. The anvil (100-200lbs) will be on a homemade 2x12 vertical stack stand in the open area where the rug is now ... yes, the rug will be removed. However, I plan to make both the forge and anvil mobile so that I can move them just outside the garage in the driveway shown in the picture when the weather is nice. When I am working inside the garage, I would plan to have the back door (back left of the picture) open to the back patio and the garage door open with a large fan blowing out for air movement. I plan to have an extinguisher handy and a CO monitor. At least initially I will be making smallish knives and axes and a friend will be doing decorative metalwork. The small table-top finishing tools (grinders, sanders, drills, etc.) will all be on the workbench on the right side. Now for the constraints (self-imposed or otherwise): 1) I will use this third bay, I will not be building an extra shop building or setting up on the back patio. 2) I don't plan to make any modifications to the construction of the garage in terms of replacing walls or ceilings, or adding extra ventilation. 3) I don't ever plan on using a coal forge in the home shop, as I will have access to those in the smithy that I train in. So now it your turn to pokes holes in the plan or give extra helpful tips that I didn't think of. Thanks in advance!

-

Hi Doctor, thanks much. Yes that's how I'm making it after having seen several of them made in the smithy I trained in. I really like the simplicity and versatility.

-

Talked to the owner again. He thinks it's either Kohlswa or Soderfors, but not sure why it's not marked. I made an offer (sight unseen so far) of $4/lb without the stand (I am making my own 2x12 stacked wood stand) and he is considering it. He priced the anvil at $1000 and stand at $400, so my offer of $740 for the anvil only is what he is considering.

-

Marc, exactly my thought. If it is worth that much then I'm out of my league, and if it's not then I need him to come way down. No idea how he got Swedish from no markings, but who knows. But it is beautiful isn't it?

-

Found this on CL in the area. He says it's likely Swedish cast steel, but has no markings so I'm not sure how he is guessing that unless just by experience. Asking $1400 including the iron stand, which is nice but I don't necessarily want to pay for. At $7.50/lb it seems steep even though it's a very nice looking anvil with very good rebound according to him. I might take a look if he's willing to come down in price, but I'll need him to come well under $1000 if I'm going to consider it. Thoughts (I know, tough without any other info). Doctor, thanks for the advice. I'll keep thinking about the tradeoffs until I can find a steel of a deal. Twisted, I did just stop by there today to look at the Kanka vs the TFS. they didn't have either in my size, but I did compare them on different sizes. I also did pick up my first pair of tongs and cross-peen hammer. all I need now is a xxxx forge and anvil ... the two biggest pieces. I already have all of the tooling for blade shaping/sharpening and handle making. I'll have to contain my excitement for a bit longer. Oh, the CL anvil is 185 lbs, but I guess you could have done that math, too.

-

Nevermind, I was not searching at the top level. 14 pages of TPAAAT and 3 pages of TPAAT. Anyway, appreciate the advice again.

-

Interesting, 99% of the posts referencing TPAAAT call it TPAAT ... guessing everyone took the Applied out and consider it more theoretical?

-

Thomas, oh boy did you send me on a wild goose chase to find what TPAAAT was (did you throw in the third "A" just to mess with me? haha). Google apparently doesn't know about your prowess either. Joking aside, sounds like I need to start talking to right people. The upper middle class suburbanites in my hood are not producing anything useful at the moment. I'm aware of Balcones Forge but will give them a closer look. 'The classes I've been taking are through a place called Pioneer Farms where they have a period-accurate (late 1800s) smithy, so all of my knowledge and experience at the moment is through them, and that's where I'll be able to apprentice if I choose.

-

Thanks for all of the quick replies. I updated my profile to show my hometown as Austin, TX. Unfortunately the guy doesn't have any in hand yet. He is ordering them when he builds up enough pre-sales to justify the order. This alone is leading me to stay away since I can't see the product first. So this ultimately became an exercise in understanding if cast steel with a [name the method] hardened face is a good anvil. He claimed the rebound was 75%, but that sounded high to my newbie ears. Thomas, I agree that searching for a great deal and anvil is fun (and frustrating at the same time). I've spent about 2-3 months looks since I started the blacksmithing classes and everything I've seen on CL, ebay, Nexdoor, FB, etc. is > $5/lb for new or vintage. My guess is that 2-3 months is not nearly long enough. Perhaps I'm not looking at the right reputable new dealers. centaur forge is certainly not cheap. Any recommendations on vendors? The good thing is that I can apprentice at the smithy for free (pay for steel only) until I get my own shop finished. I still have a lot of research on propane forges to do, too, so I'll be visiting that section of the forum soon. Price is in US$. For reference, the TFS 100lb I'm looking at is $580 and the Kanca 110lb is $660.

-

Charles, thanks for the clarification on making vs improvising. I rather like the features like horn, holes, step, etc. for what I have done and what I and my friend plan to do (knives, axes, decorative, tools). Perhaps it's a function of the training I've already received and I don't realize how I could improvise those functions in a non-London pattern anvil. I'll continue to research and learn. Any opinion about cast steel vs ductile iron?

-

Thanks for all of the tips and opinions on the use of this forum and anvils. sorry about posting the CL add. To clarify, I understand the risks of going with an imported product of questionable quality. However, I am not one of those people who thinks everything made in the US is good and everything made outside is bad. So I'd rather look at the specs and technical aspects and then make a decision based on that info + price + risk. So for now what I'm looking for more is an assessment of the pros and cons of an anvil made of cast steel, 1053 steel, middle frequency induction quench, etc. Also, I'm not interested in making my own at this point. I understand this is much cheaper and offers a certain type of satisfaction, but I have the money and not really the time right now. I'm also not interested in paying through the teeth for a vintage anvil. JlBlohm, what do you like about the kanca anvil. I have a centaur forge in town and am leaning towards the TFS 100lb from there. Thanks again.

-

Hi, I'm just getting into black/bladesmithing as an at-home hobby. I've taken 40 hours of classes so far, and am starting to set up my home shop. The smithy I trained in had TFS 100lb anvils for the students, so I am comfortable with that one and am considering buying one since they are available at in my hometown. That is about the size and style that I am looking for. However, I found an interesting post on Craiglist from a guy starting up a business. It's a great price for what could be a decent anvil (60kg for $450). It is cast steel, which I understand can be bad. But it is 1053 and tempered to 55-62 hrc. I talked to him a bit for more info, and he said they are being made in China and use middle frequency induction quench (I know nothing about that) for the hardening. He also said they are the same manufacturer that makes Cougar anvils in Australia, for what that's worth. I checked them out and they look pretty cheap with a bad flat horn design, but these horns look nice and round. I'm a total newbie at this, so can someone take a look at this add and give me their honest first opinion about it? Thank you.