-

Posts

67 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Marske, north east UK.

-

Interests

Backyard Engineering

Recent Profile Visitors

1,354 profile views

-

Thanks very much for your help with this 'twar'. Your a star. I was given the motor a couple of years ago by a work buddy and didn't get any terminal bridges with it however, I can make a few from a piece of 0.5mm brass plate I have laying around so they should suffice. Clarke do still make motors like mine, so I sent them an email asking if they could help me with a wiring diagram for it. Unfortunately, I've not received a reply from them but thanks to you, I don't need one now. Thanks again twar Gav

-

Thats good to know"Buzz". Gives me a bit more confidence in my plan of attack. Just need the motor wiring problem sorting and I'll be at it. U any good with 240v electrics Buzz?

-

I kind of had an idea that that's what it was but wasn't sure so thanks 4 the explanation. Like the saying goes "you learn something everyday" Gav

-

I like the way you used a 1/4 rod to 180 your block over, so it lined up. I may well use this technique when I drill my block. I'll see how it goes. Gav P.s. What do u mean by "buttered the block" Sorry, " buttered the wood "

-

Yeah, I lined up the 2 chunks of wood with the grains running roughly at 90° to each other. Used PVA wood glue and left them clamped up for 24hours. Just need my motor wiring up now so I can crack on with it.

-

Unfortunately all my friends use hammers and gas-axe's for a living aside from one who's a joiner. Hence, I can't find anyone to help with this

-

Thats news 2 me Frosty, altho' I don't really understand the difference between 3 phase and single phase, I always thought its 240v single. Not exactly positive about that one cheif

-

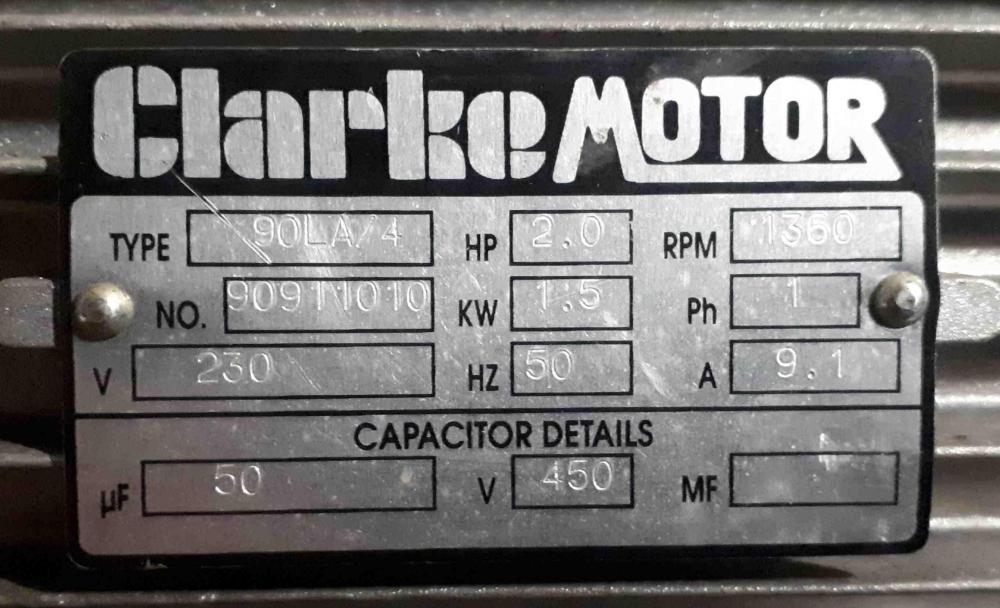

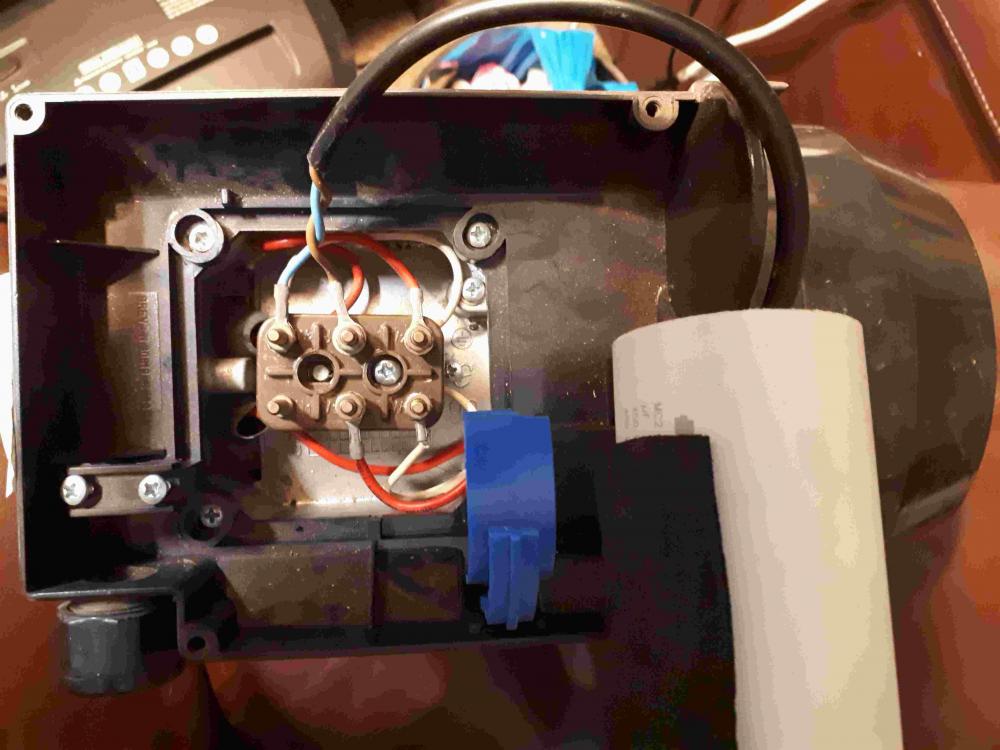

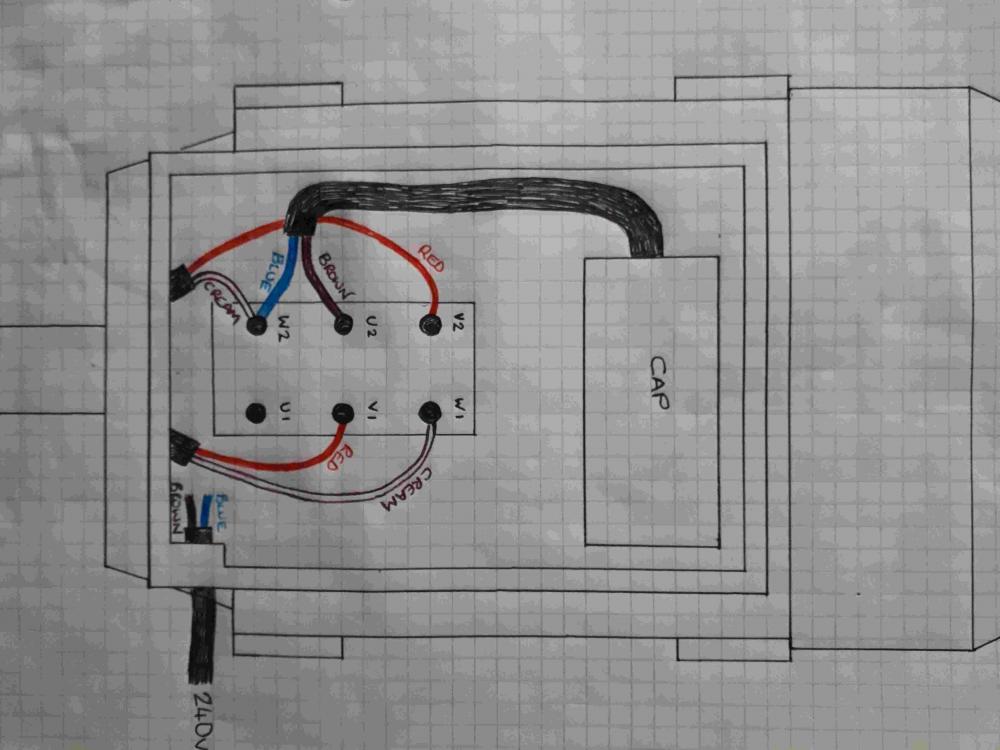

I really aren't sure which heading this should be under so opted to put it here. I have no experience of electrics apart from putting on a plug and paying the bill so hopefully someone can guide me with this. I need to wire up my single phase, 2hp motor with a 240v plug but have no clue at all. There are 6 terminals and a capacitor to consider and I've been told it's a relatively simple task. I've added a drawing of how the wires are connected on it in order so you can see it clearly and help explain it to me. I've tried looking this up online but could only find an explanation with 2 capacitor's attached to the motor so thought it best to seek out exactly what I need rather than try to interpret that. Thankyou in advance to anyone who can help. Gav

-

As soon as the anvil post is finished I've got the small problem of making my drive wheel. Getting one turned is definitely not an option as I was laid off from work last Friday, along with 30 other lads, so I now have even less money to spend on it than before. My idea is to make one from 2 bits of hard wood glued together to make a block roughly 4" × 4". It's teak apparently.I'm going to grind a 25mm wood drill bit down to 23.9mm, ish(the motor shaft is 24mm)then drill and attach the block to the motor. Then build an improvised wood lathe around that to turn the block into my wheel. Thats the plan anyway. I'll let you all know how it goes.

-

Hey Ted, I just wanted to say good luck with the build(altho' u've probs finished it now) and also that ive really enjoyed reading this thread. Im guessing your a bit like me in the fact that u like to experiment with your own idea's before copying somebody else's. What do u do for a living Ted?

-

Just a couple of pic's of my anvil post (still not fully welded)for you all to check out. The hole in the middle is so I can weld it up and achieve, at least a small amount, of solid core material. With the equipment l have to work with, I think this is about as good as I can get. The pics

-

first trial towards forging a conrod

Gavj75 replied to BeaverNZ's topic in Power Hammers, Treadle Hammers, Olivers

Epic. Your obviously a very skilled chap indeed. I wish I had access to your toy cupboard -

- 17 comments

-