Vincent Tai

-

Posts

5 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Vincent Tai

-

-

Glad to hear Mike and others think that the twisted strip will work in the NARB, I had been thinking it would create too much turbulence/air resistance for the air to be drawn in fast enough.

-

23 hours ago, DHarris said:

I found this on eBay. They seem to be pretty spendy, but I am not sure why. It looks like it would be easy to make one.

This one caught my eye, I wonder if these could be modded so hole is at the centre of each twist, and then we stick it in a NA burner. Probably would cause too much turbulence but would be a fun test.

thematrixiam,

as for making these, what about cutting some steel part way through and then twisting? with a blown burner would it matter if these static mixers are super accurate?

Vincent

-

On 4/11/2019 at 10:56 PM, Frosty said:

Welcome aboard Vincent, glad to have you. If you'll put your general location in the header you might be surprised how many members live within visiting distance.

Thank you for the information, I THINK that's where we were going, it certainly fits in with it.

Frosty The Lucky.

Thanks for the welcome Frosty. This Forum is a goldmine.

I'll get onto adding info to the header.

Vincent

-

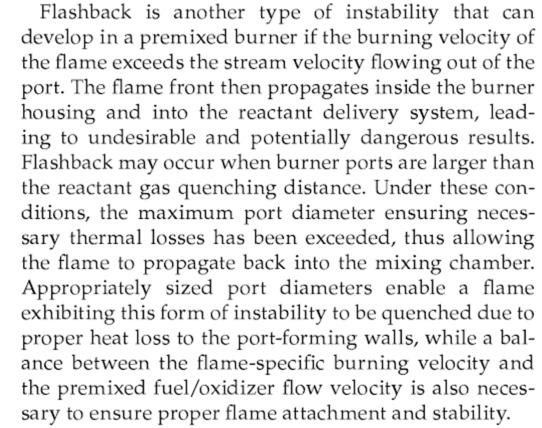

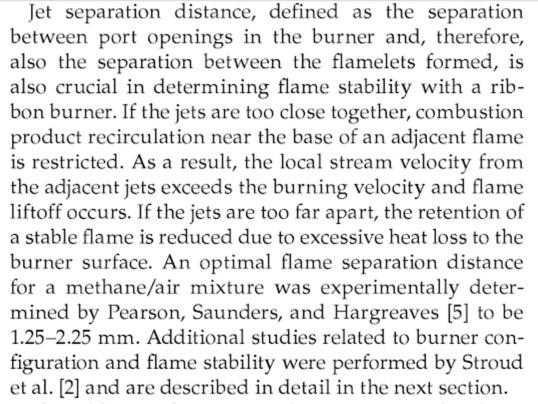

Heres a couple screenshots from a book I stumbled across. I've only had time to give one section a quick look but I think some of you guys would find something useful from this book. I think some real fine tuning could be done with the holes sizing and location in all homemade ribbon burners, NARB and blown. I've been lurking for a while, can't wait to make a NARB and hopefully get a frankenburner attached to it one day. I don't have any welding equipment so I am mulling over no weld solutions (haven't thought of a good one yet) or get a cheap arc welding machine, might get some use out of it for future projects too.

3D printed plastic burner experiments (photo heavy)

in Gas Forges

Posted

Until AFB gets his burners released for sale, I do want to try modelling/printing a few myself. With the burner pointing upwards do y'all think the printed ones would last a few months? Planning to put one in a NARB too; again nozzle pointing up. AFB; how did your printed prototypes fare; did they ever see extended use in a forge?

Or am I on a dead end, too much heat radiating to be safe? I can picture printed burners faring better in a NARB.