jlblohm

Members-

Posts

196 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by jlblohm

-

could use some anvil advice

jlblohm replied to boattlebot's topic in Anvils, Swage Blocks, and Mandrels

Im hoping it is medium carbon. Something like 4140 would be great. I found a piece of stock in the pile with a company name which is Johnson's technology which is a well known manufacturer of turbine engine parts so im really hoping it is medium carbon steel. On the plus side i know quite a few people that work for them and maybe i can get some info out of them about what the hex stock is used for and maybe an alloy. -

could use some anvil advice

jlblohm replied to boattlebot's topic in Anvils, Swage Blocks, and Mandrels

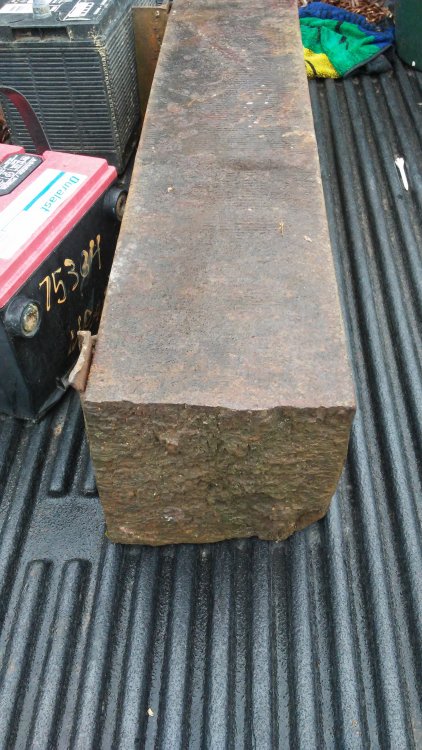

Well to get back to the subject of anvil advice i also grabbed one of the solid bars that is 3 inches by 40 inches that im going to use for my small power hammer build. But i might use it as a post anvil for a bit first. -

could use some anvil advice

jlblohm replied to boattlebot's topic in Anvils, Swage Blocks, and Mandrels

So i found 3 of the hex bars. They weren't as long as i thought but i grabbed one thats about 38 inches long and it has a 2 inch cross section. Here is 5160 spark. Hex bar spark. -

Opinion of my possible first anvil

jlblohm replied to Dark wing Duck's topic in Anvils, Swage Blocks, and Mandrels

My vulcan has really sharp edges and horn. I have the horn facing the wall so i dont run into it. I keep the vulcan with sharp edges for when i need them but that is abput the only time she sees a hammer. It was given to me by a really good friend and it is literally like brand new and i plan to keep it that way. I have other anvils with rounded edges that see most of the work. -

could use some anvil advice

jlblohm replied to boattlebot's topic in Anvils, Swage Blocks, and Mandrels

I might grab the big lengths any way. I was looking up hex bar and found a lot of it is 1018, 4140 and some is another alloy 12L14 that has lead as an alloy to make easier machining. If its 1018 it would make great tong material. It just sucks having to work the steel down to tong usable dimensions. If its 4140 it would be excellent for hammers. -

could use some anvil advice

jlblohm replied to boattlebot's topic in Anvils, Swage Blocks, and Mandrels

There was a couple hex bars in that pile. I am going back tomorrow for more after i get the gas line back in my truck. I think the one in the picture was about 12 feet long. There is another one above the one you see. It is laying on that tire under the leaf spring. I also grabbed the small bar poking out in the bottom of the picture and the other one laying on the ground at the top of the picture for making tongs. -

I pulled all of mine out of large flange bearings. I was at the scrap yard the other day and found all kinds of bearings. Look for something like this the bigger the better. If you find one like this or similar the bearing will spin out of the housing and you then cut the outer race to get to the "ball bearings". If you find one post a picture and we will walk you through getting the balls. I have thought of making a video showing different common bearings and how to get the balls out.

-

Power hammer anvil requirements

jlblohm replied to emtor's topic in Power Hammers, Treadle Hammers, Olivers

Here is a link to the hammer i built and i used 2 pieces of C-channel welded together filled with sand and capped with a section of rail. I have hardly used it because you can almost move steel as fast with hammers. I have now acquired 2sets of forklift tines a piece if steel 2x6x72 and a 7.25x7.25x30 block that weighs in at 469lbs that will be replacing the current anvil. https://www.bladesmithsforum.com/index.php?/topic/35630-60lb-power-hammer-build/&page=3 -

could use some anvil advice

jlblohm replied to boattlebot's topic in Anvils, Swage Blocks, and Mandrels

Went to my local scrap yard the other day and found this pile of solid round bars. I grabbed the one square bar that is in the right hand side of the picture. All of these bigger ones would make great anvils. -

It looks like a Vulcan with a fisher top...definetly a southern cresent anvil!

-

Anvil Identification and History?

jlblohm replied to AggieBlacksmith's topic in Anvils, Swage Blocks, and Mandrels

Im not sure about the anvil bit here is another thread with an anvil like yours.- 3 replies

-

- identification

- blacksmith

-

(and 8 more)

Tagged with:

-

Nice hammer. How are you liking the NC anvil?

-

Old double bick 252lbs anvil EW french??

jlblohm replied to OCForge's topic in Anvil Reviews by brand

It is a yorkshire pattern with some french features. Very interesting... -

New to me 190lb Hay Budden

jlblohm replied to Pyrostic's topic in Anvils, Swage Blocks, and Mandrels

I would have to agree with pyrostic that the horn is how it is supposed to be. When you look close at the advertisment the one on the left is what he has. Here is a picture of the 2 types of farrier patterns hay budden made. -

Help identifying Anvil Find

jlblohm replied to Nate Friesema's topic in Anvils, Swage Blocks, and Mandrels

The false edge does help with chipping though. Thats why you see so many vulcans missing half the face but you rarely see a chipped up fisher. The only anvils that could be milled without doing major damage would be something like a rhino anvil that is through hardened. -

Help identifying Anvil Find

jlblohm replied to Nate Friesema's topic in Anvils, Swage Blocks, and Mandrels

It is the best way to do it none the less. -

Help identifying Anvil Find

jlblohm replied to Nate Friesema's topic in Anvils, Swage Blocks, and Mandrels

Forge welding a new face on would be the best way to repair it. -

Makers Mark Triangle with the letter C??

jlblohm replied to Peppie's topic in Anvils, Swage Blocks, and Mandrels

Any pictures of the Columbian? -

Makers Mark Triangle with the letter C??

jlblohm replied to Peppie's topic in Anvils, Swage Blocks, and Mandrels

Not necessarily. There is a couple factors to take into consideration. Columbian anvils are known to be quite hard which has its ups and downs. Ups would be hard for it to take a dent from a missed blow but that missed blow might catch an edge and chip it. Newer anvils are tempered a little softer and the edges aren't as easy to chip but the face will take a dent. -

Makers Mark Triangle with the letter C??

jlblohm replied to Peppie's topic in Anvils, Swage Blocks, and Mandrels

You are in the perfect place to get a new anvil. Rhino, nimba, and mathewson metals anvils are all made in washington and reasonably priced. -

Makers Mark Triangle with the letter C??

jlblohm replied to Peppie's topic in Anvils, Swage Blocks, and Mandrels

No hardened plate. It is solid steel. -

Makers Mark Triangle with the letter C??

jlblohm replied to Peppie's topic in Anvils, Swage Blocks, and Mandrels

It is a Columbian and is excellent cast steel! -

At least he has the wool sealed and is a basically turn key unit. Better than what this guy is selling! I have no need for a forge. I have been building my own forges for quite a while. K-9JAX asked fir our opinion and we all gave him our opinion. So my honest opinion is i have seen way worse forges built and have personaly built worse. Its a little on the pricey side but he has to make money...he isn't doing it for fun.the wool is sealed and the option to have 2 inches is good. I belive it would be worth the money. So there it is...my honest opinion.

- 14 replies

-

- gas forge

- propane forge

- (and 5 more)

-

Seriously if you looked into them you would find out that is just a square hole in the door NOT glass. I see no reason for the burner to be "out of date"....i still use and make my own charcoal. People have been doing that for thousands of years. He also has video on the website of one running. He offers an option for 2 inch for $30 more. Come on guys this looks like an EXCELLENT forge for the money. Look a little deeper. If im missing something please enlighten me!!!

- 14 replies

-

- gas forge

- propane forge

- (and 5 more)

-

Looks like a Wilkinson to me with the fat throat at the horn and thick waist. But they have a little more sweep under the heal.