-

Posts

150 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Owen Hinsman

-

Thanks Chris!

-

Chris, if you got to some local blacksmith meet-ups, with plenty of cash you should be able to find an anvil. That one cost about 550 I think.

-

Just picked up a 146# Peter Wright at the NEB fall meet, along with a Picard cross peen, a hot cut hardy, and a scythe peening anvil.

-

I like that idea of a tool box on wheels. One of the other members of New England Blacksmiths uses a couple of five gallon buckets. Any thoughts on those?

-

As I don’t have my own forge (yet), I go to all the hammer ins and smithing meets I can find. As my tool collection grows, the little tote bag I’m using just isn’t enough. How do you guys and gals organise your tools, whether in the shop or at meets?

-

The largest tongs I have are about 27” long, but with some really odd jaws: 58698029287__65549A62-080E-4B0F-8B71-E2A6AB3F2BE2.MOV

-

I looked into it some more and it appears that the little cone around the tang is part of the piece, and covered in some sort of tacky, black material.

-

So I was thinking about sword canes, and I had an idea for a spike that would sort of pop out of the base of the cane when a button was pressed. It would lock out when extended, and a little door would cover it when retracted. Any idea as for how the mechanism would work?

-

How can I sharpen my tools to a razor edge? I don’t have any fancy machinery, just a few files, a vintage whetstone, a diamond file, and a Dremel. I made a nice hook knife for my dad for Christmas out of some O1, but it is still not sharp enough to cut paper.

-

I quite like that saw with the stepped teeth. It seems like it would be easier to forge than a saw with triangualr teeth.

-

How would I go about smithing a saw? I’ve looked on YouTube, but have only found a few videos. I want to make something for cutting ice.

-

Thanks for the help! I was guessing that from the tar adhesive on the tang and the cast steel label it was from the late 1800s.

-

So I found this old gouge/chisel in my box of goodies, and began my research. But all the info I could find was from November 2007, and a timeframe of 1822 - 1965. Any help would be greatly appreciated. Here’s the website I found the info: http://swingleydev.com/ot/get/174006/thread/

-

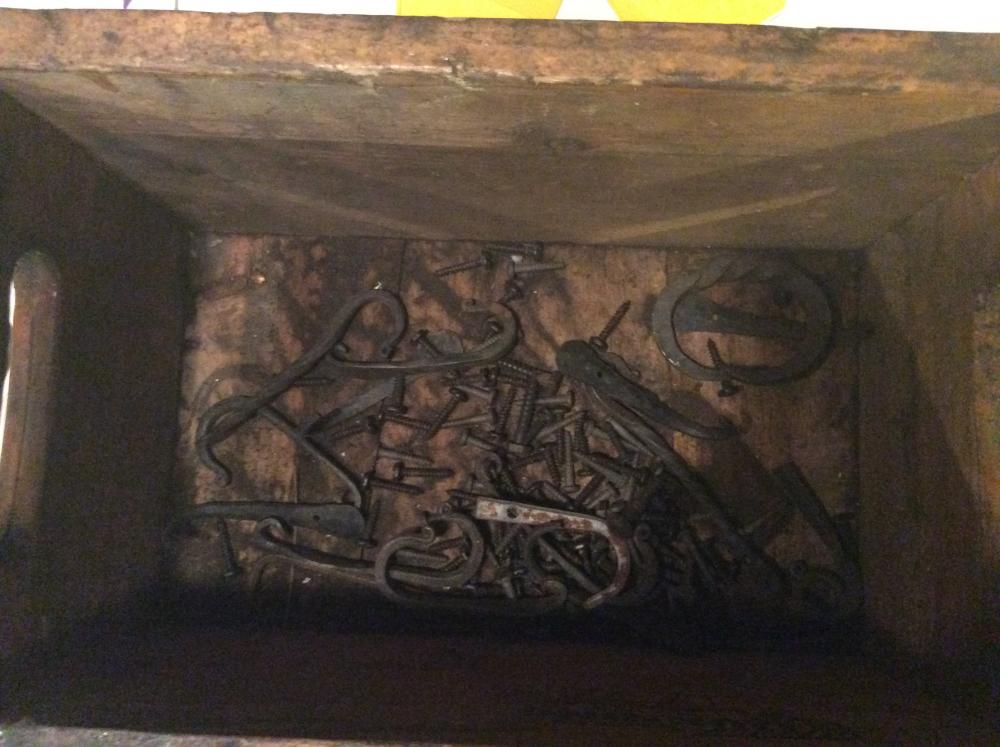

You may remember a massive stash of hardware that followed me home in May. I wa going through it (again) and I found these beauties. The file is 19 and 1/2 inches, aka as long as my arm, and the gouge is nine inches. The little cone around the tang of the gouge looks and feels to be pitch or tar of some sort.

-

How would I go about making throwing darts? Not the bar kind, but something larger for hunting small game. I have tried doing this in the past, but the dart just tumbled in the air.

-

A couple of weeks ago I picked up 70+ lbs of random hardware. I also went to the NEB Spring Meet today and picked up some other stuff. WARNING: PIC HEAVY

-

What did you do in the shop today?

Owen Hinsman replied to Mark Ling's topic in Blacksmithing, General Discussion

Das, what fair are you going to? I'll be at the NEB Spring Meet. is it there? -

What did you do in the shop today?

Owen Hinsman replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice job Dylan! -

What did you do in the shop today?

Owen Hinsman replied to Mark Ling's topic in Blacksmithing, General Discussion

Daswulf, you can get rose cutouts online BTW, i am not trying to advertise, just help a fellow smith. -

Yes I currently forge. I don't have a personal forge, but I go to open bench. Where can I get some of that static line? it could be very useful even for non-climbing uses.

-

13 and one half

-

I am right here. You, sir, have been very helpful, pointing out all the things I don't know (A lot). I never considered that a single hook would be better then a triple or quadruple hook. Wouldn't the off balance hook be detrimental to accuracy? and its MA’AM not sir

-

As I have now awakened, I shall now answer your questions. getting from tree to tree is mostly because i want to see if i can, and as for your idea, i will most defininetly give it a go.

-

And now I am laughing my harbor seal laugh.